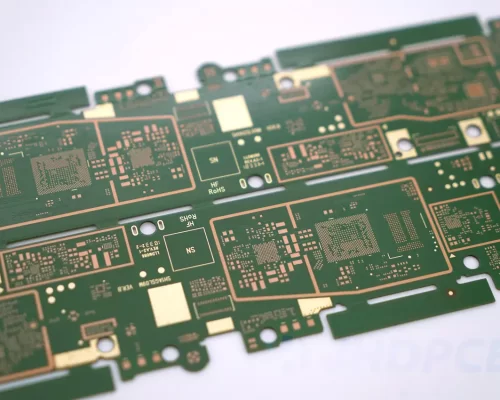

Aviation PCB manufacturing

The Role Of PCBs In The Aviation Industry, New Technologies And New Industry-Specific Needs Challenges:

The Role Of PCBs In The Aviation Industry, New Technologies And New Industry-Specific Needs Challenges:

Role of PCBs in Aviation:

PCB is involved in flight control, communication and navigation, airborne electronic equipment, sensor systems and other aspects in the aviation industry, providing high reliability and stability.

New Technologies in Aviation:

New technologies in the field of aviation PCB cover embedded component technology and embedded component technology to improve system performance and reliability, providing more advanced and reliable solutions for the design and manufacturing of avionics equipment.

Industry-Specific Challenges:

Due to its special nature, avionics equipment has very strict requirements for high reliability and safety. Therefore, the design and material selection of PCB need to take into account a variety of extreme environmental conditions as well as ensure the performance and stability of communication and navigation systems at the same time.

The application of circuit boards in Aviation:

Printed Circuit Boards (PCBs) are integral components in the aviation industry, facilitating the operation of critical systems in aircraft and spacecraft. The aerospace sector relies heavily on PCB technology for its reliability, performance, and adaptability to demanding environments.

- Flight control system: Various key equipment in the flight control system, such as autopilot, flight management computer (FMC), roll and pitch rudder, etc., rely on PCB to transmit and process flight control instructions to ensure the stability and safety of the aircraft.

- Communication and navigation system: Communication navigation equipment, radar systems, and radio high-frequency communications transmit and process navigation and communication signals through PCB to ensure accurate positioning and communication.

- Airborne electronic equipment: Aircraft monitoring, control and information display such as instrument panels, displays, and flight recorders require circuit boards to realize circuit connections and data transmission.

- Airborne sensor system: The circuit board can manufacture various sensor modules for data collection, processing and transmission to monitor aircraft status and environmental parameters.

- In-flight entertainment system: PCB transmits and displays multimedia data for the entertainment screen and audio equipment in the cockpit.

PCB Development Trends In Aviation Industry:

As a pivotal component in aerospace technology, Printed Circuit Boards (PCBs) continue to undergo rapid evolution to meet the demands of the dynamic aerospace industry. From avionics systems to satellite communications, the role of PCBs in aerospace applications is indispensable.

- High-frequency and high-speed transmission technology: PCBs required by the aviation industry will tend to adopt more advanced high-frequency and high-speed transmission technology. PCBs need to use low dielectric constant and low-loss materials to reduce transmission line losses, enhance signal integrity and impedance matching.

- Lightweight and compact design: By using flexible PCB, high-density interconnect (HDI) technology, blind via and buried via designs, etc., a thinner and more compact design can be achieved to reduce the size and weight of the PCB.

- High reliability and safety requirements: Any PCB failure may lead to serious consequences, so the design and manufacturing of aerospace PCBs will tend to adopt higher quality standards and stability to ensure their reliability in harsh environments and high pressure conditions .

- Environmental adaptability: PCBs will tend to have stronger environmental adaptability and be able to operate stably under various extreme environmental conditions, including high temperature, low temperature, high humidity, high pressure and vibration.

- Advanced material technology: Aviation PCB will adopt more advanced material technology, such as high-frequency dielectric constant, low-loss dielectric materials, high-temperature tolerance materials, etc., to improve the performance and reliability of PCB.

- Thermal management and heat dissipation design: In high power density and high temperature environments, more advanced heat dissipation design technology will be used to ensure the stability and reliability of PCBs in high temperature environments.

The Development Prospect Of Aviation PCB Technology:

The future of PCBs in the aviation industry is brimming with promise and potential. With rapid technological advancements, expanding markets for UAVs and small satellites, emphasis on reliability and safety, and integration of environmental sustainability, PCB manufacturers have ample opportunities to drive innovation and growth in the aviation sector.

Technological innovation and progress: With the continuous development of science and technology, high-frequency and high-speed transmission technology, flexible PCB technology, embedded component technology, thermal management technology, etc. in aviation industry PCB need to be improved to provide more possibilities and opportunities for aviation PCB technology.

Market demand growth: With the rapid development of the aviation industry and the popularization and application of avionics equipment, the civil aviation market continues to expand and improve the performance reliability and safety requirements of avionics equipment. Aviation PCB technology will have more market space and development opportunities.

Application of emerging technologies: The continuous emergence of emerging technologies in recent years has also provided new opportunities for the development of aviation PCB technology. Applications such as artificial intelligence, the Internet of Things, and drone technology will promote the development of aviation PCB technology in the direction of intelligence, automation and interconnection.

International Competition and Cooperation: Through cooperation with advanced foreign companies, learning and introducing advanced aviation PCB technology and management experience will help domestic companies gain greater market share in the international market.

Aviation PCB Application.

- Instrument panel

- Display screen

- Flight recorder

- Air pressure sensor

- Temperature sensor

- Accelerometer

- Autopilot

- Flight management computer (FMC)

- Roll and pitch rudder

- Radar system

- Audio equipment

- Fuel system

- Hydraulic system

- Alarm system

- Cockpit display

- Satellite

- Spacecraft

- Radio high-frequency communication equipment

Why Choose JHD Aviation PCB:

High-frequency PCB: High-frequency PCB uses low dielectric constant and low-loss materials in the aviation industry, optimizes wiring design to reduce transmission line losses, enhances signal integrity and impedance matching, etc.

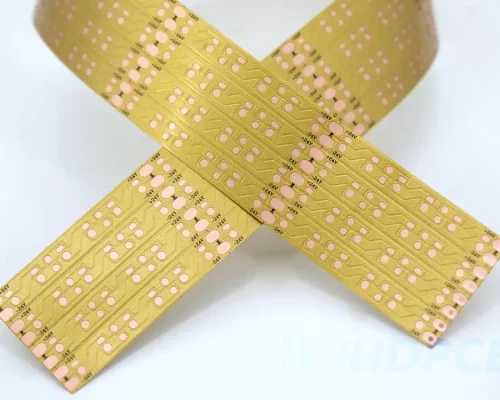

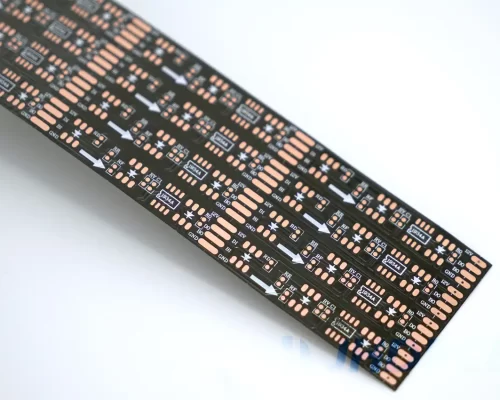

Flexible PCB: Flexible PCBs are increasingly used in the aerospace sector, especially in compact and lightweight designs. Flexible PCBs use flexible materials and foldable designs to meet the flexibility and lightweight needs of avionics equipment.

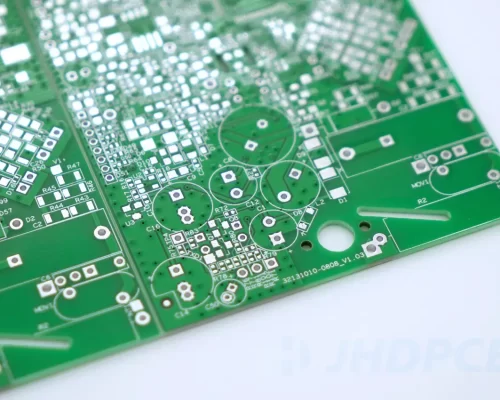

Multilayer PCB: As the demand for high performance and high density in avionics equipment increases, multilayer PCB is used more and more frequently. Multi-layer PCB has high-density interconnection (HDI) technology, blind and buried via design, inter-layer stacking of RF and digital signals, etc., which can improve the integration and performance of PCB.

Ceramic PCB: The aviation industry uses ceramic circuit boards mainly as the basis for power-led technologies. When deciding whether using ceramics will be beneficial for a desired application, the necessary process conditions need to be evaluated using a combination of calculations and balancing the pros and cons.

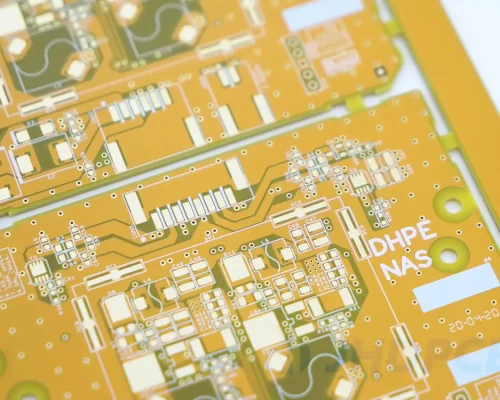

FR-4 PCB: FR-4 is one of the most dominant board types in the aviation industry PCB market. FR-4 has the advantages of high strength, excellent moisture resistance, light weight, low cost and fire resistance, making it widely used in the aviation industry, mainly in radar systems, satellite tracking systems and autopilots.

- ISO 9100

- AMS2750E

- AS478N

- AS5553A

- AS9006A

- AS9100D

- AS9101E

- AS9102B

- MIL-50884

- MIL-PRF-31032

- MIL-PRF5511

Choose high-quality materials:

In the aviation industry, reliability and durability are must-have requirements. In such applications, the circuit must operate continuously and without failure for long periods of time. The general rule is to use high-quality materials and components that will last in the market for a long time.

Correctly determine tolerances:

Tolerance is one of the important items when designing PCB. It ensures that the PCB design has the correct tolerances and has adequate clearances, drill holes and spacing for better heat dissipation.

Use a highly protective coating:

PCB facing materials should be selected to protect against heat, moisture, water and vibration, and withstand the worst conditions. The coating is then sprayed with an acrylic base to protect the final printed circuit from contamination or accidental short circuits.

Use a highly protective coating:

PCB facing materials should be selected to protect against heat, moisture, water and vibration, and withstand the worst conditions. The coating is then sprayed with an acrylic base to protect the final printed circuit from contamination or accidental short circuits.

Strict testing before leaving the factory:

Some aerospace PCBs require rigorous testing in special environments. Some PCBs need to be tested in a vacuum area and at negative temperatures. If PCBs are designed for use in geostationary or low-orbit satellites, they must perform extreme temperature testing to ensure the reliability of the PCB.

- 1.High temperature resistance: Since aerospace electronic equipment is often in a high temperature environment, polyimide (PI) and polytetrafluoroethylene (PTFE) have high temperature resistance.

- 2.Corrosion resistance: There are some corrosive substances in the aerospace environment, which requires the use of materials with good corrosion resistance, such as special polyamides and special coatings.

- Moisture resistance:In a closed environment, humidity can be an issue. Electronic devices and circuit boards can malfunction due to moisture. Such as nano coating, normal temperature fluorine coating, etc.

- Radiation Resistance:Depending on the spacecraft’s location in the Earth’s atmosphere, it may have to withstand radiation or harmful RF. Because these types of interference can wreak havoc on communications and other circuit operations, circuit boards need to be resistant to them, such as boron polyethylene.

- Fire resistance:The aviation industry has strict requirements for fire safety, so it is necessary to use materials with good flame retardancy, such as polystyrene (PS) and Australian flame retardant epoxy resin.

JHDPCB has been continuously working hard to produce better PCBs for customers. With our state-of-the-art facilities, advanced manufacturing processes, and experienced team, we are confident that we can meet and exceed your PCB expectations. We understand the critical role PCBs play in aerospace applications where precision, durability and performance are critical. Our strict quality control measures and compliance with industry standards ensure the reliability and safety of our products. Please feel free to contact us to discuss how we can support your PCB requirements for aerospace applications. We hope you will choose JHDPCB as your trustworthy PCB partner.

Aviation PCB manufacturing