JHD PCB Assembly

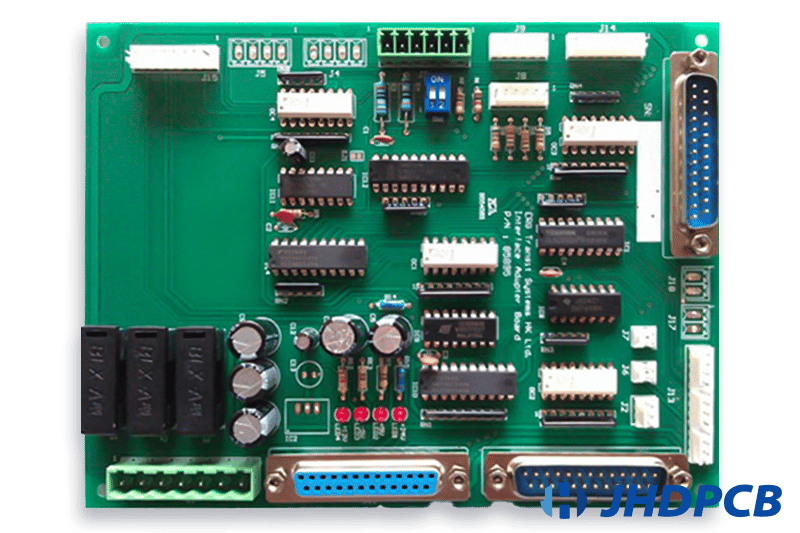

The PCB assembly business is the assembly of components on a PCB. After the customer receives the PCBA, it can be used as long as it undergoes a simple product matching test. JHDPCB has more and more PCBA demand. Therefore, we carry out pcb and pcba business, aiming to provide customers with one-stop service, strengthen the cooperation stickiness with customers, which is a useful supplement to our PCB fabrication.

content

What Does PCBA Means? What Is PCB assembly Board?

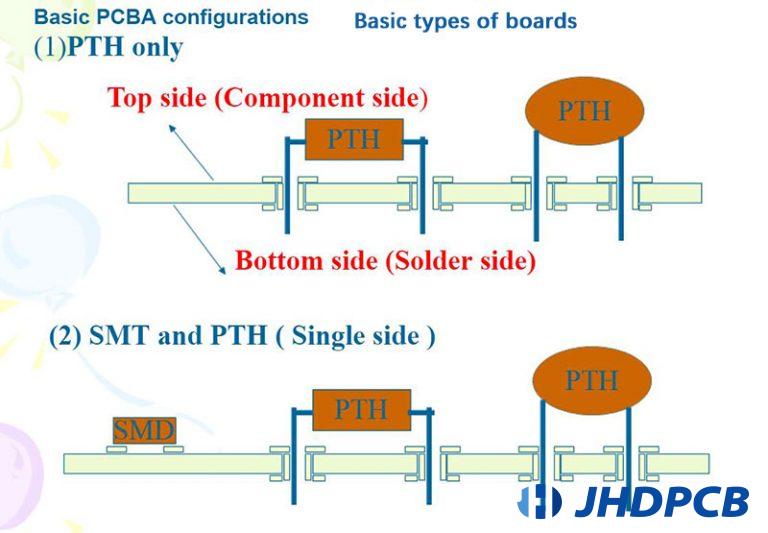

PCBA is the abbreviation of Printed Circuit Board Assembly. It refers to the use of SMT patches or DIP to paste components and other electronic accessories on the PCB. SMT and dip are both methods of attaching components to PCB. The difference between them is that SMT does not need to drill holes on PCB. While dip needs to infix the component pins t into the drilled hole on the PCB. The assembling requires both passive and active components. The list of these electronic components include:

Resistor SMD capacitor

Transformer Diode

ICs Transmitter

SMT PCBA:

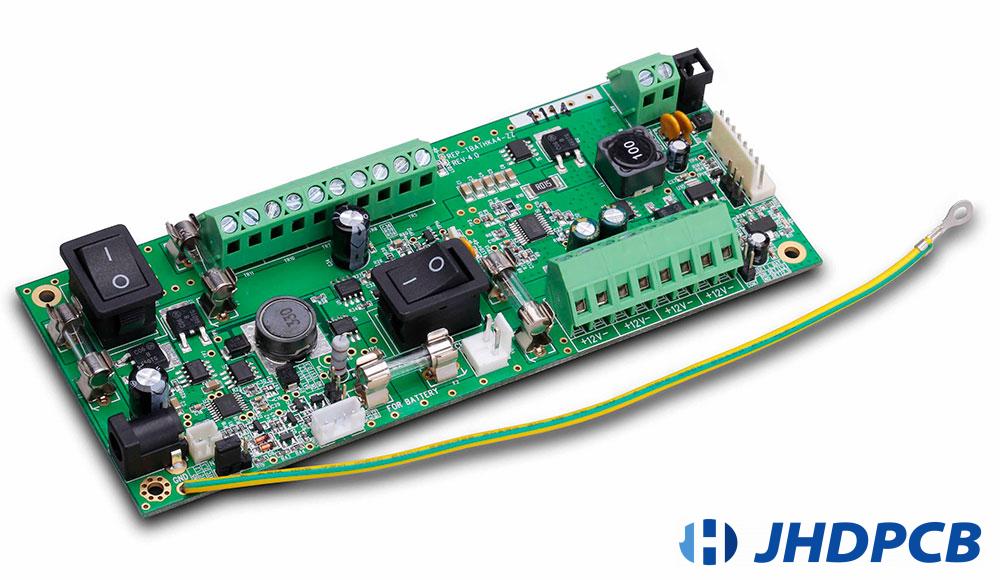

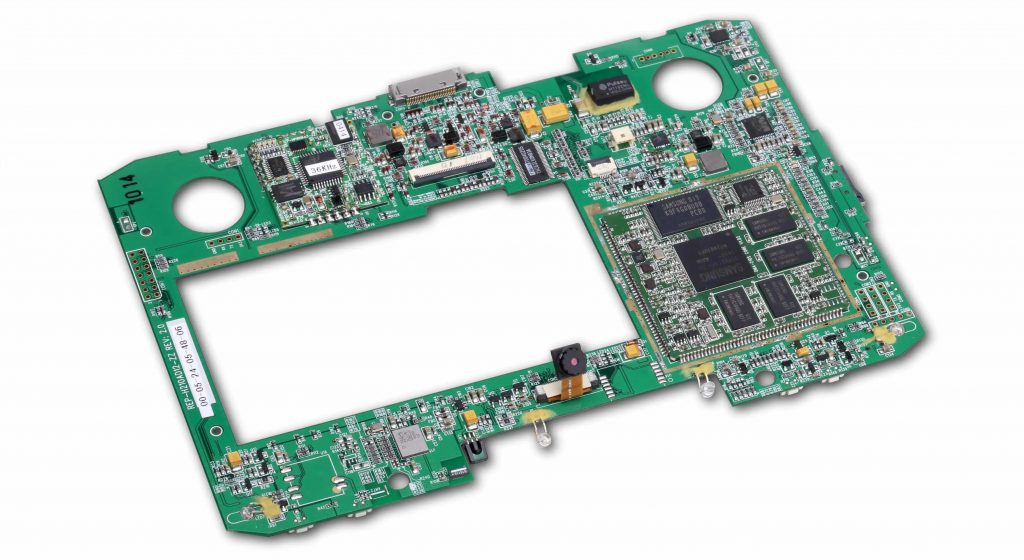

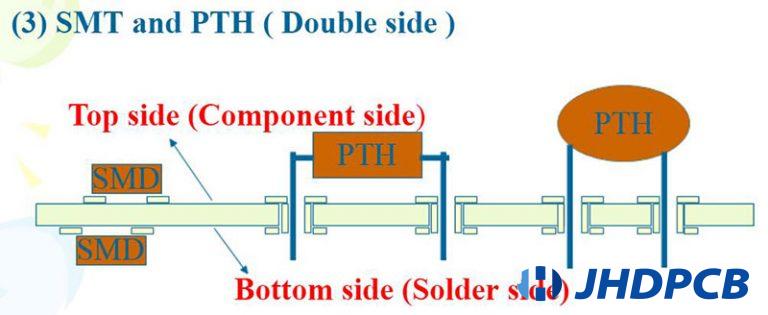

Smt pcba (surface mounted technology) refers to the use of SMT equipment to mount s micro miniature components on PCB. Full production process of smt pcba includes PCB board orientation, solder paste printing, components mounting, reflow oven and pcba fabrication inspection. And we generally recommend using SMT assembly for surface mount.

DIP PCBA:

Dip pcba refers to “plug-in”, infix the component pins into pcb holes. You must drill holes(PTH) on the PCB surface to insert through-hole components. This process is called through-hole assembly.

If some components are large in size and are not inadequacy for mounting, dip pcba way needs. Its main production processes are: sticking adhesive on the components, components plug-in, pcba inspection, wave soldering, and pcba fabrication inspection.

There are two ways to assemble printed circuit boards. You can choose automatic soldering to install the electronic components on the PCB. The most popular soldering technique is wave soldering. It is used in traditional through-hole components.

Another common technique for soldering components on PCBs is reflow soldering. It is mainly used for SMD components. You can also use hybrid welding techniques. Some professionals also use manual welding. But this is a very difficult task.

What Are Our Advantages Of PCB Assembly?

We manufacture PCB by ourselves.

The quality of the PCB can be well controlled, and the time of PCBA production can be shortened. Because once the PCB is finished production, we can proceed to PCBA manufacturing right away.

Advanced full-automatic pcba production lines.

We have introduced advanced full-automatic pcba production lines from Japan, South Korea and other countries. The equipment is tailored for the mass production of medium and high-end products with high quality requirements, such as network communications, automotive electronics, security, consumer electronics, LED display and AI, intelligent wear and so on.

Industry-leading PCBA technology.

In order to better cooperate with our customers and realize the perfect presentation of PCB from design to final finished product. We invest a lot of energy to break through the industry PCBA technology. We can paste 01005, BGA spacing of 0.2mm, QFN, CSP, con and other components. The incoming materials are checked at every level through 9 inspection processes, with a daily production capacity of 40 million points and top-level quality control and testing equipment. After multiple testing processes, they are strictly checked at every level, with high standard anti-static and 10000 square meters of dust-free production workshop. Every pcb pcba products will pass optical inspection. We undertake OEM and ODM businesses of various electronic products such as patch, plug-in, post welding, and testing and assembly.

More advantages and capabilities about JHD PCB Assembly;

What Requirements May PCBA Have On PCB?

The pcb must meet the pcba fabrication requirements in field of pcb dimension, distance of solder pads, etc, so that facilitate the PCBA soldering process. PCBA processing has the following requirements for PCB boards:

- Regarding the dimension of the PCB, the width of the PCB should be greater than or equal to 50mm and less than 600mm, and the length of the PCB should be greater than or equal to 50mm and less than 1200mm. In order to facilitate the pcba manufacturing, the PCB needs to be designed as a panel or set.

- PCB frames width: >5mm, the distance between pad and board edge>5mm.

- According to the acceptance criteria of IPC600A and the process requirements of PCBA. It is required that the upward bending degree of the PCB must be less than 1.2mm, and the downward bending degree of the PCB is less than 0.5mm. The warpage of the PCB can be calculated by the formula of maximum deformation height ÷ diagonal length, or it can be tested with a plug gauge.

- Fiducials(Mark point) of PCB board. The shape of fiducials should be standard circle shape with square triangle frames; Fiducials size; range from 0.8mm to 1.5mm; Fiducials’ surface requisites: the surface should be flat, slick and sly, no oxidation, no grime; Fiducials circular requirements: There should be no solder mask within 1mm; For more PCB design rules see our Design Guidance blog.

What Is The Difference Between the PCB&PAB Assembly?

Although the difference between PCB and PCBA is only one letter, it represents something completely different.

PCB refers to a blank PCB without any components. After purchasing the PCB, the customer needs to arrange the assembly of the components by himself. PCBA refers to the PCB with components. Customers only need to send the BOOM LIST to JHDPCB, and we can provide one-stop PCB procurement services, saving customers a lot of time and improving their procurement efficiency.

What Are the Main Characteristics of PCBA?

Many customers feel a little unfamiliar with PCBA. Although they often hear PCBA, some people do not know what the main features of PCBA are. If you can have more understanding of PCBA from multiple different angles, so that PCBA will have more guarantees in the use and matching of subsequent products, so now let’s take a look at the specific characteristics of PCBA.

- The assembly density of pcba is relatively high;

- PCBA products are relatively small in size and light in weight.

What is PCBA Manufacturing Process?

Base PCBA configurations;

| Manufacturing PCBA Processes | ||

|---|---|---|

| Sequence | Steps | Description |

| Pcba manufacturing Stage 1 | Material Kitting | Before PCB assembly, need to prepare all materials. |

| Pcba manufacturing Stage 2 | Feeder Set up | Feed the materials to the smt pcba, pcba production. |

| Pcba manufacturing Stage 3 | Solder paste printing-DEK | Print solder paste onto solder pads. |

| Pcba manufacturing Stage 4 | Pick/Place SMD-CP & IP | Pick and place pcba components to the smt pcba. |

| Pcba manufacturing Stage 5 | Reflow | Pcba across the reflow oven. |

| Pcba manufacturing Stage 6 | Smt pcb QC | Smt pcb inspection. |

| Pcba manufacturing Stage 7 | Hand load PTH | Load the components in to holes. |

| Pcba manufacturing Stage 8 | Wave soldering | PCBA across wave soldering machine. |

| Pcba manufacturing Stage 9 | Touch up | Cut the unnecessary tin feet and touch up. |

| Pcba manufacturing Stage 10 | Final QC | Final QC of pca. |

| Pcba manufacturing Stage 11 | In Circuit Test | In circuit test of pcba. |

| Pcba manufacturing Stage 12 | Burn- in test | pcba burn- in test. |

| Pcba manufacturing Stage 13 | Functional test | Functional test pcba. |

| Pcba manufacturing Stage 14 | Box Build & final test | Pcba final test. |

| Pcba manufacturing Stage 15 | OQA | Outgoing Quality Assure. |

| Pcba manufacturing Stage 16 | Packing | Packed with foam and holder. |

Meet all your PCBA project needs with JHDPCB.

JHDPCB is a trusted and experienced PCB manufacturer. We provide customers with high-quality PCBs with rich experience and first-class precision equipment, not limited to any type of PCB. Just contact us and send your Gerber file and request for material and quantity and we will give a price shortly.

We also offer a free PCB file check to help you get the correct PCB design before full production and avoid costly mistakes. All our designers are compliant with the ISO9001:2015 quality management system and our in-house quality control department will verify that your prototype meets our and your high standards before we send it to you.

The full-link production line also provides assembly services after you complete the PCB manufacturing. We can do everything from prototype assembly to commissioned PCB assembly, turnkey PCB assembly, and partial or full assembly according to your unique needs. All turnkey services are IPC Class 2&3 compliant and ISO 9001:2015 certified.

From small batches to large batches, different types of PCBs to multi-variety assembly, we will take advantage of our advantages and ingenuity to help all customers solve their PCB needs. For more product information, please contact us via online live chat. Or contact JHDPCB customer service staff by email. We will use our expertise to do our best to meet all your PCB project needs.