FR4 PCB

FR-4 PCB refers to the PCB processed with FR-4 copper clad laminate. It has good electrical insulation function, excellent processing performance and flame retardancy, so it is widely welcomed by the market. Almost all double-sided and multi-layer PCBs on the market use FR-4 material. At the same time, some special FR-4 PCBs are also used in the market, such as high TG value FR-4 PCBs. The higher the TG, the higher the thermal, chemical and mechanical stability of the PCB. JHDPCB can produce 1-20 layers of FR-4 PCB to provide you with one-stop purchasing service to meet all your PCB needs.

What are the types of FR-4 produced by JHDPCB?

Regular FR4 PCB: It is a standard FR-4 PCB with a heat resistance of about 130°C and a CTI value of 175.

High TG FR4 PCB: High TG FR4 PCB refers to the TG value≥150, such as fr4 tg150, fr4 tg155, fr4 tg170, fr4 tg180, fr4 tg190

High CTI FR4 PCB: High CTI FR4 refers to CTI>600. CTI is the relative tracking index.

If The Operating Environment is Humid, It Is Necessary To Consider CTI>600 FR4.

Lead Free FR-4 PCB / Halogen Free FR-4 PCB: These types of PCB meets environmental protection requirements

High frequency FR4 PCB: This is a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as frequency above 1GHz. This type of high frequency signal transmission generally requires tight impedance control. If you are not familiar with PCB circuit impedance, you can learn it through our “Impedance Control On PCBs: What For? How To Control? Impedance Calculation“.

According to the number of layers, it can also be divided into single-sided FR-4 PCB, double-sided FR-4 PCB, multi-layer FR-4 PCB and HDI FR-4 PCB.

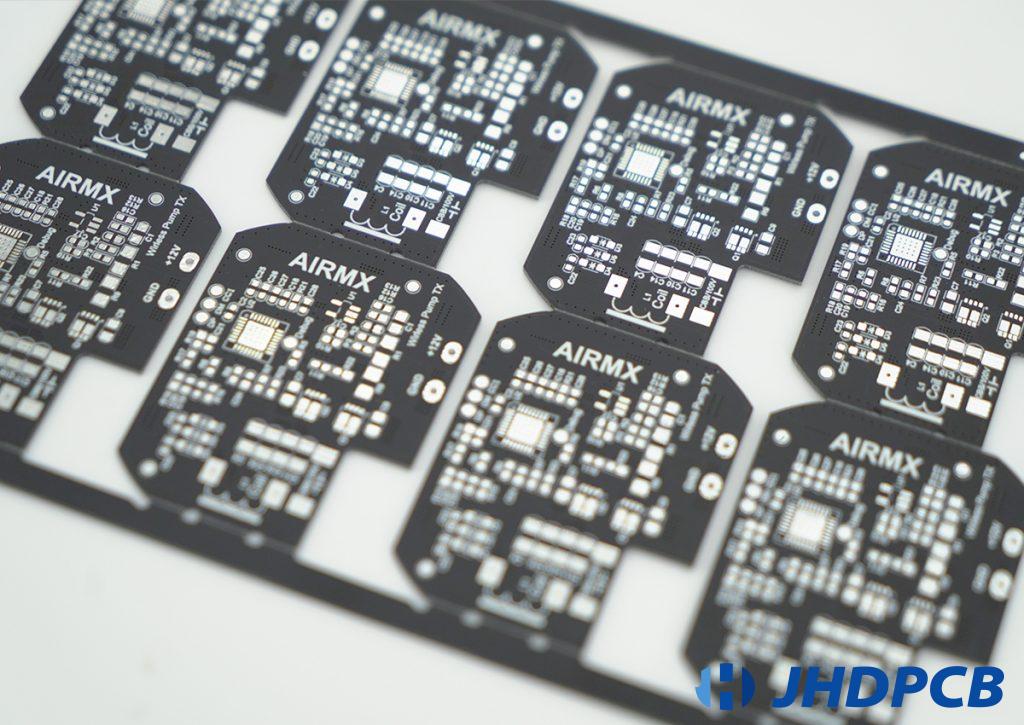

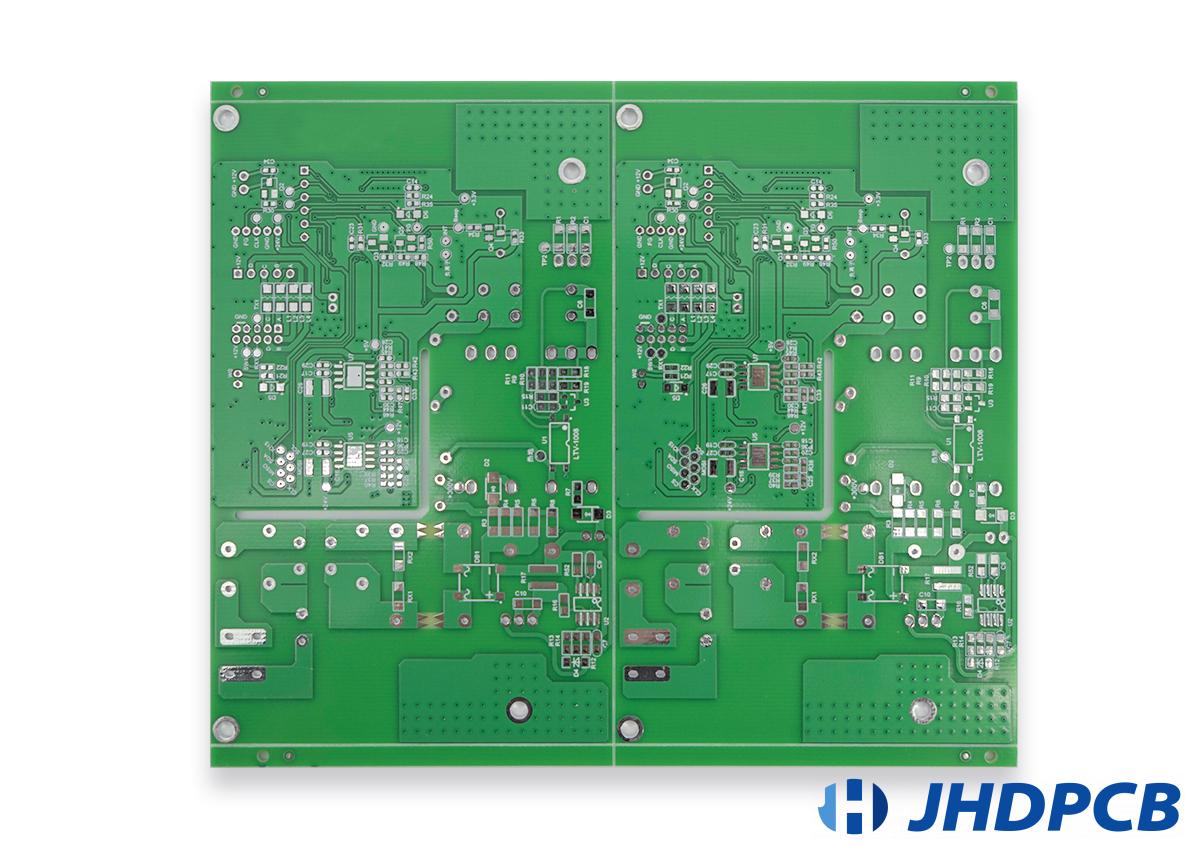

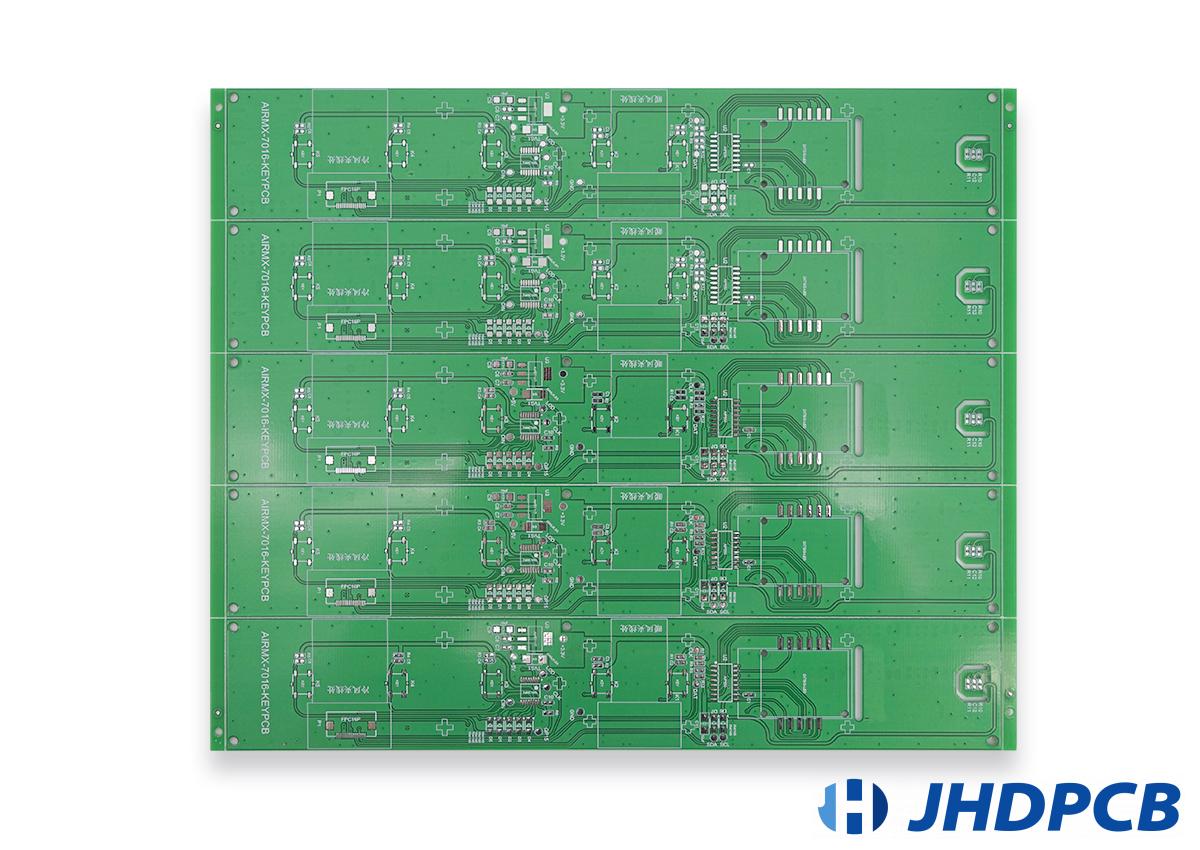

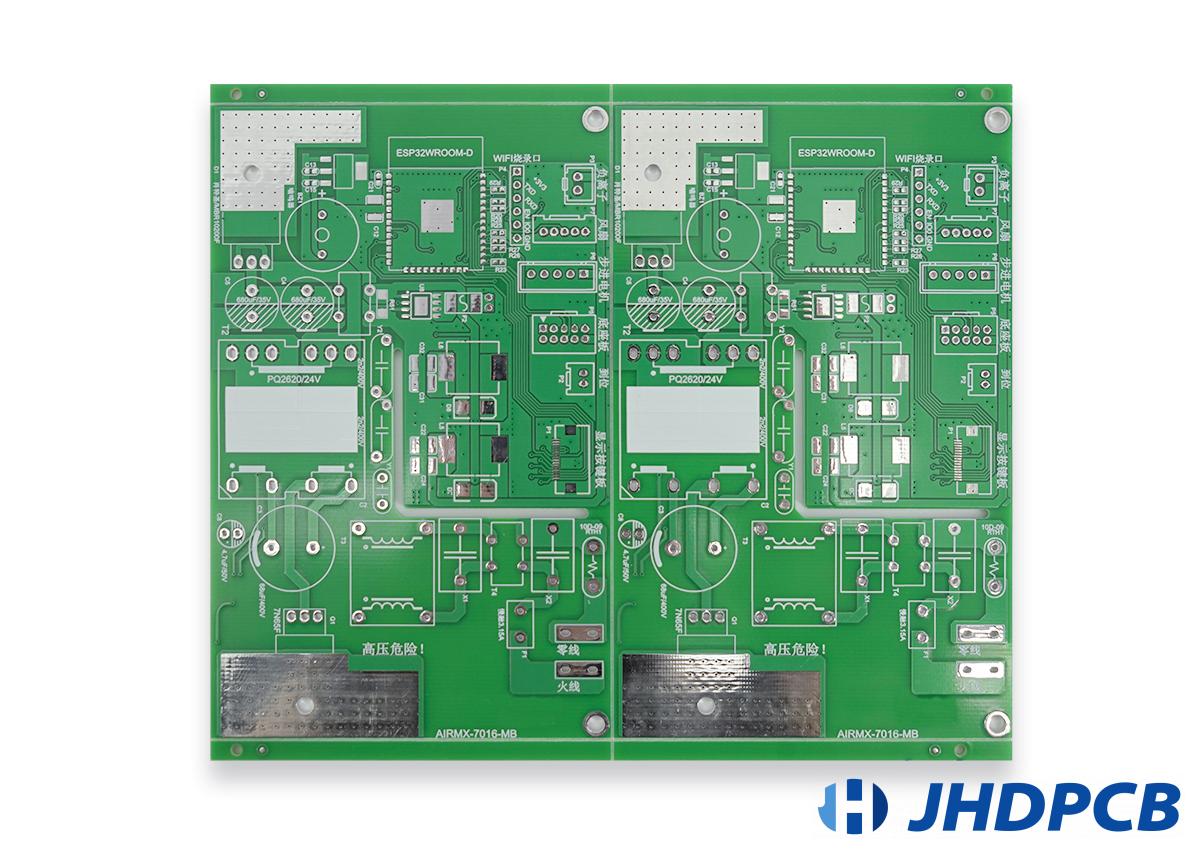

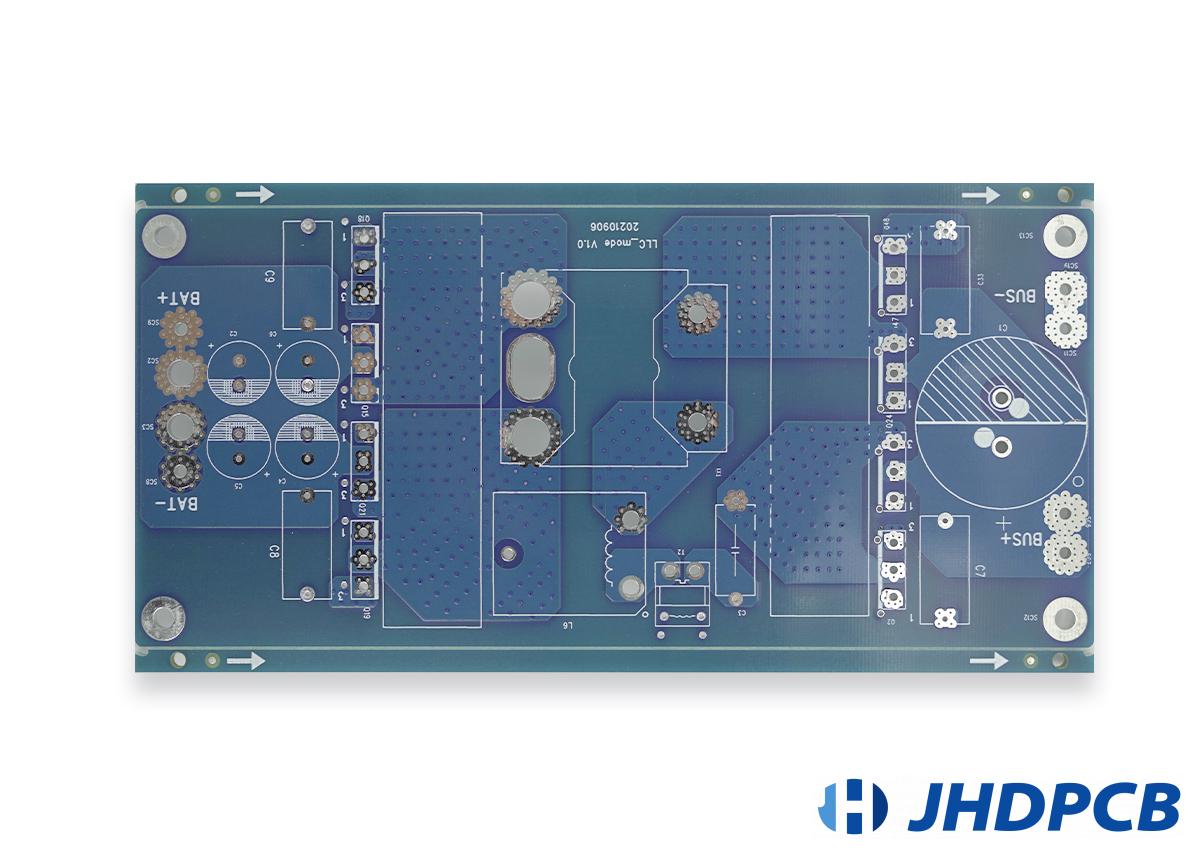

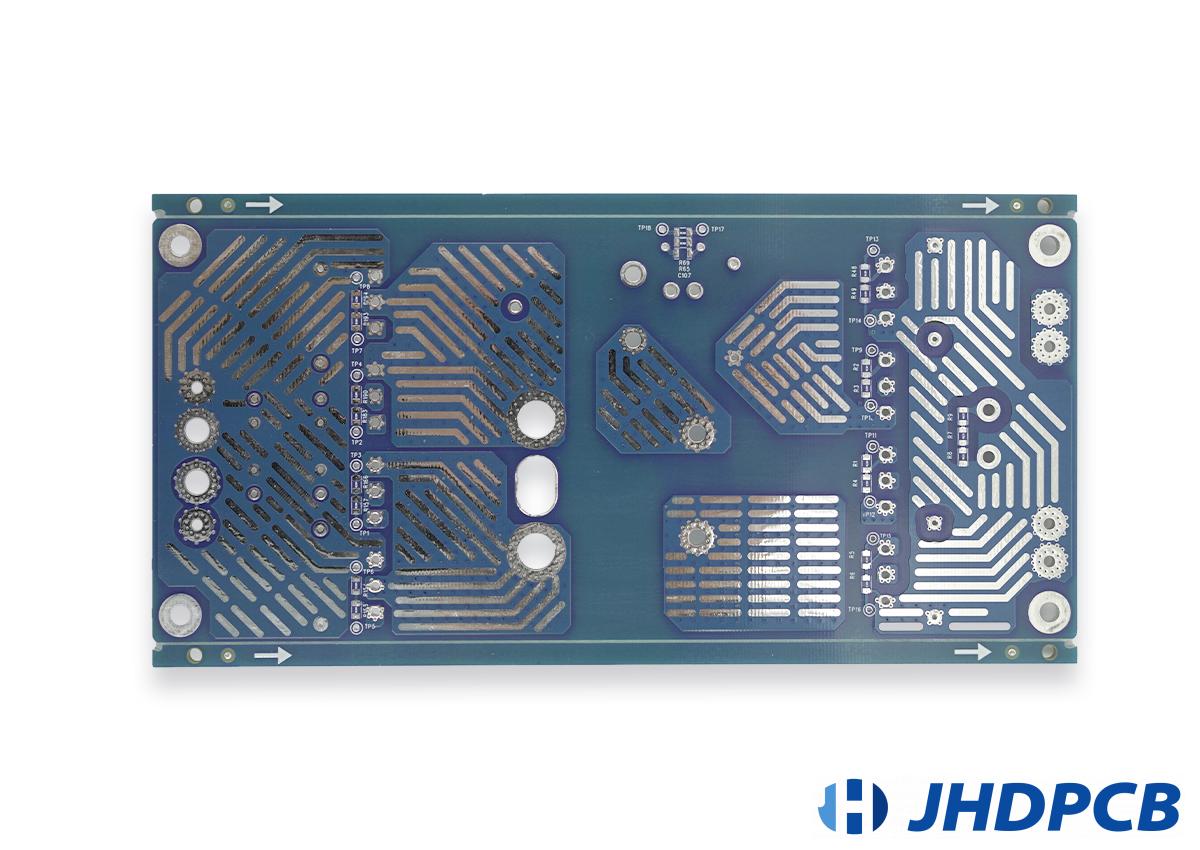

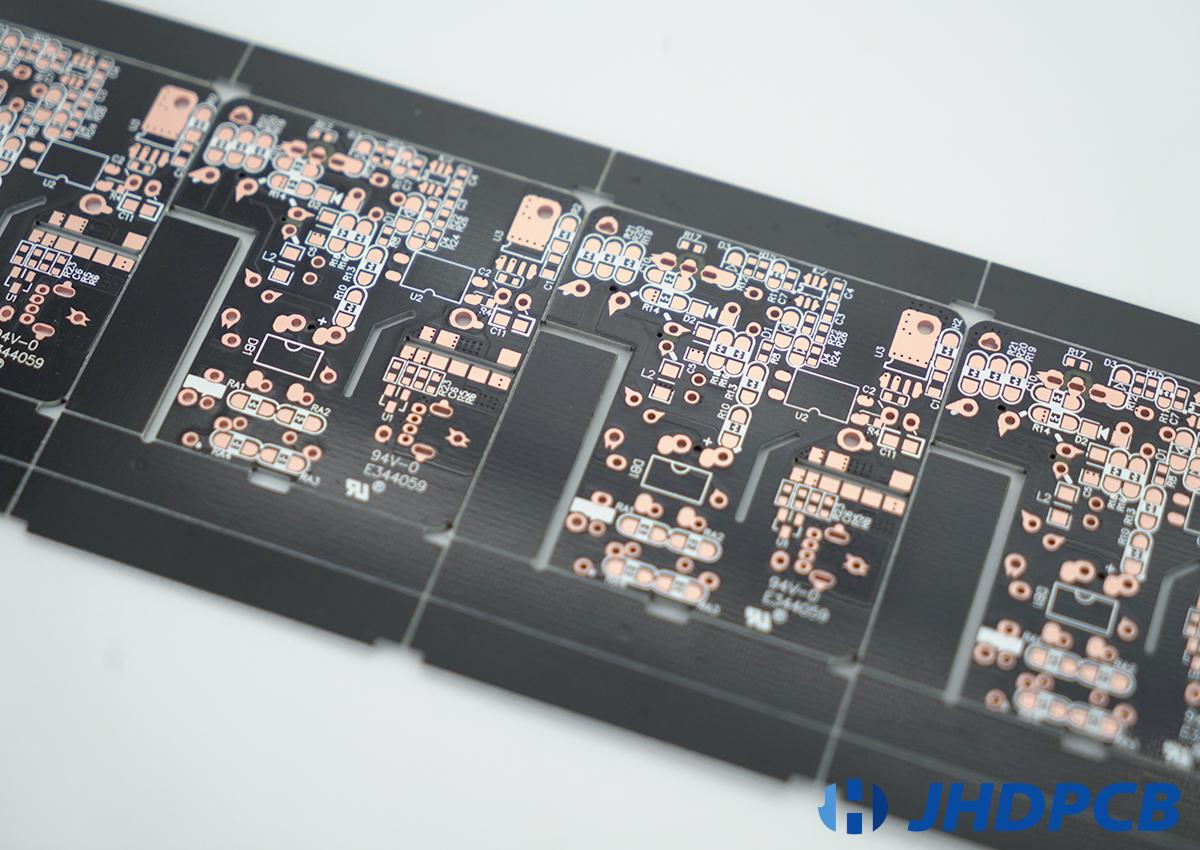

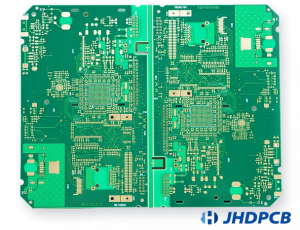

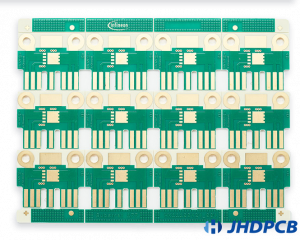

JHDPCB FR4 PCB Product Case Show:

What is FR-4 PCB?

The “FR” in the name is short for flame retardant, and the 4 designates a material class. The most basic layer of FR4 material is glass fiber. Fiberglass woven into a thin cloth-like FR4 sheet, surrounded and bonded with flame retardant epoxy, ensures the necessary structural stability of FR4. Therefore, FR-4 PCB made of FR-4 material has good electrical, thermal and mechanical properties.

What Should Be Paid Attention To When Purchasing FR4 PCB?

Flame retardant. For safety reasons, FR-4 PCB shall comply with UV 94V-0 standard. Because when the PCB is short circuited or overheated and catches fire, the fire will go out immediately without causing fire.But at present, some PCB manufacturers in the market use non-flame retardant FR-4 production in order to save their cost, which has a great potential safety hazard. JHDPCB promises that all the FR-4 PCBs we produce are made of well-known brands of CCL that meet the 94V-0 standard, to know which materials we can use, please refer to TYPES AND DATABASES OF COPPER CLAD LAMINATE(CCL).

Another important parameter of FR-4 is the TG value. Which refers to the glass transition temperature (TG). The range is between 115°C and 190°C, the higher the TG, the higher the temperature that the FR-4 PCB can withstand. The FR4 PCB produced by JHDPCB has a fr4 material properties TG value of up to 280°C. More detailed TG value introduction for PCB production. Please see HIGH TG PCB product page.

FR-4 PCB thickness. Common fr4 pcb board thickness ranges from 0.6-3.0mm, such as fr4 0.8mm, fr4 1.0mm, fr4 1.6mm, fr4 2.0mm. The thickness of fr4 pcb board less than 0.6mm is called ultra-thin FR-4, and the thinner the fr4 pcb, the more difficult it is to produce.

FR4 PCB Below 0.6mm is Called Ultra-Thin PCB, And JHDPCB Can Produce Ultra-Thin Boards Of 0.2mm.

Fr4 substrate copper thickness. The normal copper thickness is 1OZ (35UM), but if the circuit carries a high current, 2OZ or 3OZ copper thickness is required. JHDPCB can produce FR4 PCB with 1-6OZ copper thickness. If the copper thickness exceeds 3OZ, it is called heavy copper PCB. For more information, please refer to our heavy copper PCB product page.

JHD FR4 PCB Production Line:

JHDPCB is the leading FR4 PCB manufacturer in China, we have more than 10 years of experience manufacturing full range of FR4 PCBs. From simple 1 or 2 layers PCBs to high complexity multi-layer PCBs or HDI PCBs. Our goal is to be China’s TOP5 PCB manufacturer. We are committed to providing high-quality, industry-leading PCBs on time at competitive costs.

For more of our advantages, please visit Why to JHDPCB. No matter what kind of FR-4 printed circuit boards you are looking for or boards of any other material, JHDPCB can help you in supplying high-quality PCB in any quantity while maintaining extreme quality and on-time delivery.

Check Out The JHD FR4 PCB Production Line Video:

What Are Advantages Of FR4 Material?

- Wide operating temperature range (50°C to 115°C).

- Higher T g values (about 180°C).

- Provides good mechanical properties to maintain circuit board structural integrity.

- Compared with other materials, the cost is lower.

- Excellent flame retardancy.

- Good electrical properties.

- Low hygroscopicity.

According to the requirements of the application products, select some special FR4 PCB, such as high TG PCB, high CTI PCB. Combined with environmental protection requirements, some lead-free or halogen-free PCBs are used. JHDPCB can produce these special PCBs for your one-stop shopping.

Please note that although fr4 circuit board has many advantages and low cost, not all products should use FR-4 PCB. With some high frequency products, such as 5G products, it is not suitable to use FR-4 PCB . Instead, a high-frequency circuit board substrate should be used. Fluorine resin, PPO or PPE resin and modified epoxy resin. Fluorine-based dielectric substrates (such as PTFE) with the lowest dielectric properties are typically used for products with frequencies of 5GHz or higher.

FR-4 usually uses bromine, a chemical element called halogen that is fire resistant. It replaces G-10, another compound with lower resistance in most applications. JHDPCB can produce lead-free or halogen-free PCBs to meet some boards with environmental protection requirements.

FR4 has a good strength-to-weight ratio. It does not absorb water and maintains a high and good insulating ability in dry or wet environments. In addition, FR-4 has good machining performance, it is easy to do shape processing and can maintain certain rigidity, and the price is relatively low, which is one of the best choices for PCB production.

What Is The Maximum Temperature A FR4 PCB Can Withstand?

In PCB design, the same monitoring of PCB temperature requirements will cost more than balloons and ice cream. You need to know how much heat a PCB may bear before it begins to suffer structural damage, especially if it is deployed in a high temperature environment.

As you know, FR4 means the flame retardant rating of the PCB. FR4 PCB is made of multi-layer fr4 fiberglass epoxy resin laminate. Since the physical characteristics of fr4 pcb material are consistent, it is preferred among manufacturers.

FR4 PCB is very strong when exposed to high temperature, but its physical properties will change at a certain temperature. The heat resistance of FR4 is expressed by TG or glass transition temperature, at which it changes from solid state to soft and rubbery state. Generally, the rated Tg of FR4 PCB is 130 ° C.

In other words, if a PCB with a rated temperature of 130 ° C is heated above its glass transition temperature, it will lose its solid state form. Not only is your mechanical structure unstable, but also the electrical performance of PCB will decline when it exceeds the rated TG. This is why the importance of FR4 maximum temperature must be considered when designing PCBs for the applications where the temperature exceeds the typical TG value.

Medium high tg-pcb: exceeding the typical maximum temperature of FR4.

If the application requires a fr4 circuit board with a higher Tg value, you need to select a fr4 pcb material with a medium or high Tg value. The maximum temperature of medium TG PCB usually exceeds 150 ° C, while the rated temperature of high Tg PCB exceeds 180 ° C. PCB with higher Tg value also has better moisture resistance and chemical resistance, as well as stronger physical structure under thermal conditions.

Unless otherwise specified, manufacturers will use low Tg PCBs for manufacturing. PCB with medium and high Tg is usually more expensive. Materials such as S1141 and s1002-m are commonly used in the production of high Tg PCBs. Due to the high glass transition temperature, the lamination of high Tg PCBs involves a lot of heat. In terms of price, the high Tg PCB is more expensive. Some applications require a high Tg PCB.

What Are The Important Things To be Aware of When Using FR4 At The Highest Temperatures?

A common error is to use the TG value to determine the operating temperature of the PCB. When selecting the correct FR4 PCB, always allocate a margin of at least 20 ° C. For example, a lower TG FR4 of 130 ° C should have an operating temperature limit of 110 ° C.

As a PCB designer, you need to understand the thermal adjustment technology in the design. The power regulation module will generate heat, so appropriate heat dissipation technology shall be adopted. The use of heat sink or heat dissipation through hole helps to prevent the hot spot from overheating, so that the temperature of PCB exceeds its limit.

TG rating and PCB operating temperature are not the only factors that determine its function in high temperature environment. The operating temperature limit of a single component must also be considered in the design.

How Thick is The FR4 PCB Normally?

The most commonly used fr4 pcb board thickness range is 0.4-3.0mm, such as fr4 2.0mm, fr4 1.6mm, fr4 1.0mm,fr4 0.8mm, PCB manufacturers define fr4 pcb boards with a thickness of less than 0.6mm as ultra-thin FR-4 pcb.

What Does FR4 Is Short For?

The “FR” in the name is short for flame retardant, and the 4 designates a material class. FR-4 is flame retardant, and the flame retardant grade is 94V-0 or higher.

Are PCBs Made of FR4?

Most PCBs are made of fr4 pcb material, especially double-sided PCB and multi-layer PCB. Of course, there are also PCBs that use other materials, such as cem1, cem3, FR1, FR2, aluminum PCBs, etc. Different materials are selected according to different applications. To learn more about the classification of PCB basic materials, please refer to our corresponding articles.

Why we Use FR4 Substrate?

First of all, as a base material, FR-4 material has excellent electrical insulation, moisture resistance, can also withstand a certain high temperature, and is light in weight. It is suitable for making double-sided circuit boards and multi-layer circuit boards.

What is a Good FR4 PCB Thickness?

There is no standard answer to this question. The thickness of FR4 PCB ranges from 0.2mm to 5.0mm. The common FR4 PCB thickness is FR-4 1.0mm/FR-4 1.6mm.Please select the appropriate FR4 PCB thickness according to the space of the application product.

What is FR4 Made Out Of?

FR-4 is a kind of plate-shaped material made by dipping electronic glass fiber cloth or other reinforcement materials with resin, covering one or both sides with copper foil and hot pressing. Its main raw materials are copper foil, glass fiber cloth, resin, etc. Electronic copper foil accounts for about 40%, glass fiber cloth accounts for about 27%, and resin accounts for about 23%.

Does FR4 Material Absorb Water?

FR4 material has low water absorption, usually between 0.1%-0.4%, and is suitable for FR4 PCB fabrication.