Aluminum PCB

When your product operates at a high temperature and requires a circuit board with good heat dissipation performance. The first choice is the aluminum PCB. Because the heat of the components is relatively large, if they are not dissipated in time, the lifespan is easily attenuated, and even burns out immediately. Aluminum substrate PCB is an excellent thermal conductive material, which can quickly transfer the heat of components to the radiator.

What is Aluminum PCB?

Aluminum PCB is kind of metal core PCB. Aluminum PCB is a metal-based copper clad laminate with good heat dissipation. They are also known as Aluminum circuit boards, MCPCB (Metal Clad Printed Circuit Board), IMS (Insulated Metal Substrate), Aluminum substrate pcb, aluminium core pcb etc. Actually they all refer to the same kind of PCB. Among all metal core PCBs, aluminum PCBs are the most common and popular type. The base material is composed of an aluminum core and an insulating layer, which can efficiently dissipate heat, cool the components, and prolong the life of the components. At present, aluminum PCB is considered as the solution for high-power LED applications, such as for LED street lighting, car headlights, LED high bay lights etc.

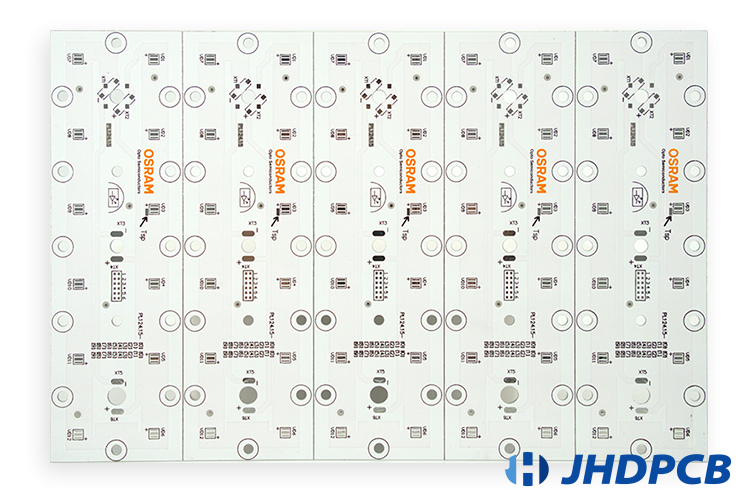

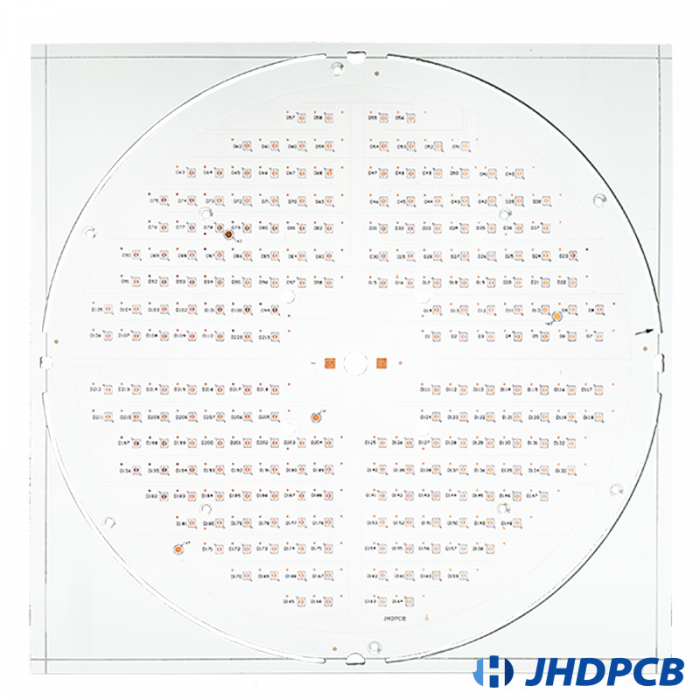

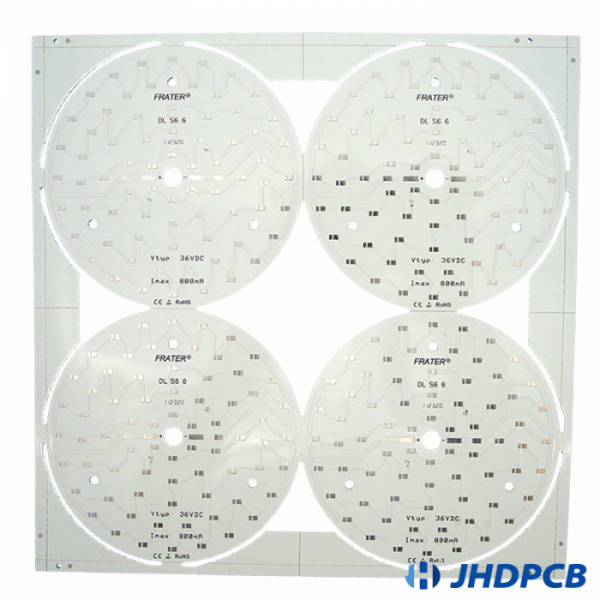

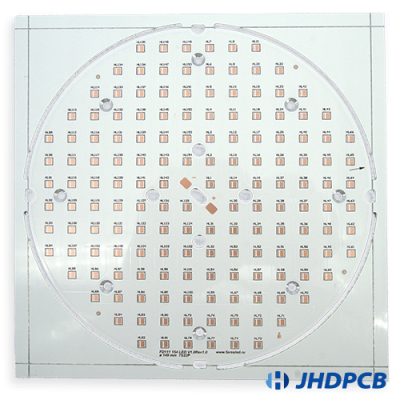

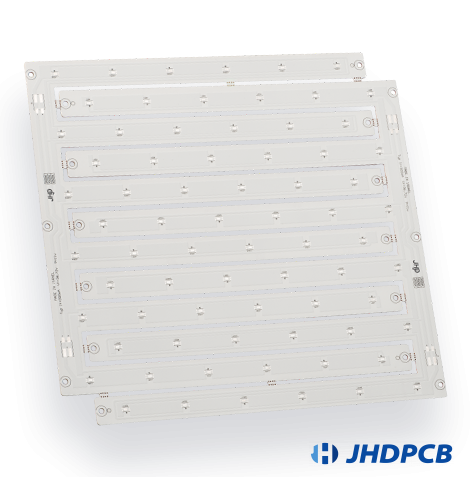

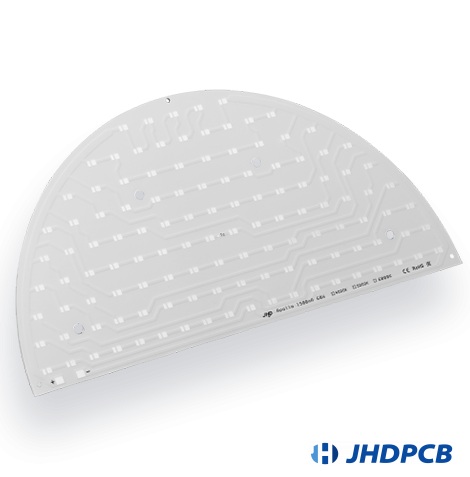

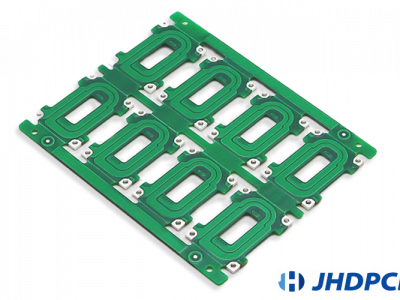

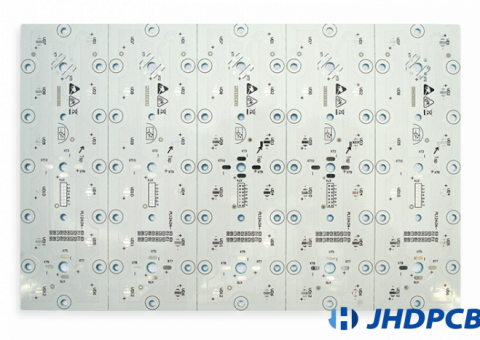

Some Cases Of Aluminum Pcb Produced By JHDPCB:

What are JHDPCB’s Advantages In Aluminum PCB?

JHDPCB – China’s top 5 aluminium pcb board manufacturers. Has helped global 2K + aluminum substrate demand customers to complete a series of one-stop new project development to implementation such as design, sampling, and lamp bead placement. Save worry and effort, and help global customers achieve projects at the most affordable price.

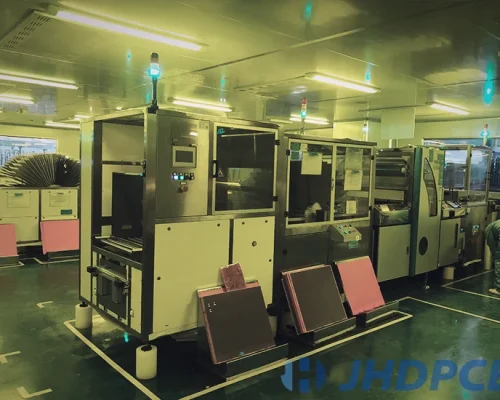

Large-scale production – equipped with 4 fully automatic single-layer PCB production lines and 2 fully automatic double-layer PCB production lines. We can reduce costs through mass production and provide customers with the most cost-effective PCBs. Check out the JHD PCB manufacturing facility.

Excellent procurement supply chain management – We reduce material costs through centralized procurement and large-scale procurement of raw materials, such as aluminum copper clad laminates, photosensitive solder mask ink, etc.

Experienced Production Team – We have been engaged in aluminum-based PCB production for more than 12 years, and supported by an experienced production team, we can provide customers with reliable quality aluminum-based PCBs.

Fast Delivery – To shorten the delivery time. Everything is manufactured under one roof with our state-of-the-art equipment. We have many brands of laminates in stock, such as aluminum copper clad laminates. More lead times can be found in “PCB Quick Turn“.

JHD Aluminum PCB Production Equipment Workshop:

How Are Aluminum Substrate PCBs Produced?

| Sequence | Steps | Description |

|---|---|---|

| Aluminum Pcb Fabrication Stage1 | PCB Sheet Cutting | The size of aluminium pcb sheet is 1200*1000mm or 1500*1000mm, we cut them to custom PCB panel size. |

| Aluminum Pcb Fabrication Stage2 | Grinding and cleaning | It can helps PCB exposure film and the copper layer connect very closely |

| Aluminum Pcb Fabrication Stage3 | Circuits exposure and development | Transfer the circuits graphics from the dry film to the PCB |

| Aluminum Pcb Fabrication Stage4 | AOI circuits inspection | Check if the circuits is broken or short circuit, etc. |

| Aluminum Pcb Fabrication Stage5 | Circuit boards cleaning before solder mask | Clean the PCB to avoid subsequent solder mask defects |

| Aluminum Pcb Fabrication Stage6 | Cover with solder mask | Solder mask can ensure that some places of pcbs will not be soldered when the subsequent PCB SMT is carried out. |

| Aluminum Pcb Fabrication Stage7 | Baking | Bake to dry solder mask. |

| Aluminum Pcb Fabrication Stage8 | Silkscreen printing | Print logo,PCB or circuit information. |

| Aluminum Pcb Fabrication Stage9 | PCB shape processing | Include holes drilling, router,V-cut or punching |

| Aluminum Pcb Fabrication Stage10 | Finished PCB testing | Use e-tester to test every pcs of pcb and avoid short circuits. |

| Aluminum Pcb Fabrication Stage11 | Surface treatments | Include OSP, HASL, Lead free HASL, ENIG |

| Aluminum Pcb Fabrication Stage12 | FQC/QA | Manual inspection for aluminum pcb defects. |

| Aluminum Pcb Fabrication Stage13 | Packing | Protected with foam, packed in cartons and taped. |

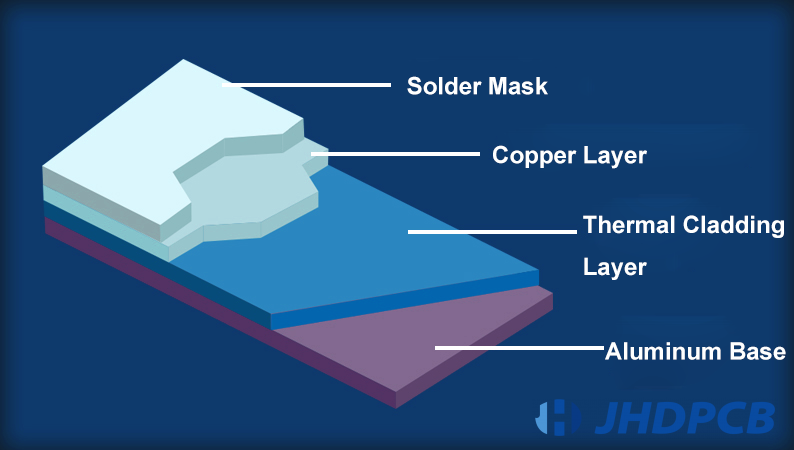

What is The Structure Of Aluminium Core Pcb?

Aluminum Base:

This layer consists of aluminum alloy metal. The use of metal aluminum makes aluminium backed pcb has better thermal conductivity and is suitable for high-power products. In addition, aluminum alloy also has a certain rigidity, which can support components well, making it suitable for large-size PCB design.

Thermal cladding layer:

The thermal cladding layer is usually made of FR4 prepreg(fr4 1080) or thermal adhesive film. The dielectric layer has relatively low thermal resistance and is ideal for conducting heat. The thermally cladding layer absorbs heat when current flows through the circuit. Then transfer to the aluminum base, and finally dissipate heat through the aluminum base. The thickness is generally about 50 μm to 200 μm.

The aluminum PCB has excellent thermal conductivity performance, suitable for products with large heat dissipation requirements. JHDPCB can produce aluminum PCB with thermal conductivity up to 10W/m.k.

Copper layer (Circuit Layer):

The copper layer (Circuit Layer) is usually a layer of copper foil, ranging in thickness from 0.5 to 20 oz. After correct etching, it can realize the function of conduction, which is the most important layer of the PCB. Thicker copper layers mean more current-carrying capacity for the circuit.

Solder Mask:

The solder mask can prevent the circuit layer from directly contacting the air and prevent the oxidation of the circuit board. There are other optional protective film layers such as: conformal coating. It helps protect aluminum surfaces from unwanted scratches and etching.

JHD's aluminum PCB manufacturing capabilities.

| Item Content | Description |

|---|---|

| Layer Counts: | single-sided/double-sided |

| Material: | Aluminum core, Copper core, FR4 covering |

| Thermal conductivity: | 1.0~2.0W/(m*k) |

| Board thickness: | 0.4-4.0mm |

| Via process: | Vias not covered, tenting vias, plugged vias, Filled vias. |

| Surface finish: | ENIG gold, HASL(LF),OSP, Immersion Silver,Immersion Tin, Electroplated nickel gold,,ENEPIG |

| Min. hole size: | 0.8mm |

| Thickness of copper: | 1-20oz |

| Min. spacing: | 4mil |

| Impedance control: | ±10%,50Ω and below:±5Ω |

| Shape tolerance: | ±0.15mm |

| Lead time: | 2-3 days |

| Solder mask color: | Black, matte green, green, yellow, red, white, purple, matte black |

| Silkscreen color | Black, white etc. Customized colors. |

JHDPCB is one of the top 5 aluminum aluminum pcb manufacturer in China, and we have been committed to providing customers with cost-effective and high-quality aluminum PCBs. We have a full set of automated production equipment and precision testing equipment for metal PCB (aluminum core pcb, copper PCB) production. Over the years, we have been focusing on the R&D and manufacturing of metal circuit boards, Years of experience in aluminum PCB manufacturing. We can be your best source for purchasing aluminum base PCB boards when you need them.

For more of our advantages, please visit Why to JHDPCB. When you need aluminum-based PCB, please let us know. Our customers rely on us to deliver on time. JHDPCB have been dedicated to providing PCB products for various companies in Fortune 500 companies or start-ups.

Check Out The JHD Aluminium PCB Production Line Video:

content

What Are The Applications Of Aluminum PCBs?

LED lighting: LED PCB is the best solution for LED lighting, especially for some high-power lighting.

LED TV backlight: Aluminum PCB is used for LED TV backlight, which can dissipate heat well and prolong the service life of TV.

LED display: MC PCB are used in large LED displays, especially outdoor displays.

3D Printer: Aluminum PCBs are used for the hot bed of 3D printer, which can transfer temperature well and has natural advantages.

Power supply equipment: switching regulator DC/AC converter, SW regulator, etc.

Communication electronic equipment: high frequency amplifier; transmitter circuit.

Automotive: car headlights PCB, electronic regulators, igniters, etc.

Power supply: module converter, solid state relay, rectifier bridge, etc. Learn more about PCB power design.

What Should We Pay Attention To When Purchasing Aluminum PCB?

1. PCB Thickness:

According to the size of the product, choose the appropriate thickness of aluminum PCB. The thickness of commonly used aluminium core pcb is between 0.8mm-8.0mm

2. Copper thickness:

The choice of PCB copper thickness is related to the current through the circuits. In the case of a certain line width, increasing the copper thickness can make sure the circuit can bear a larger current. The normal thickness of the aluminum substrate is 18um-75um (0.5OZ-2OZ). Above 2OZ, heavy copper PCB is recommended. JHDPCB can produce heavy copper PCB with copper thickness from 4 OZ – 12 OZ.

3. Thermal Conductivity:

Thermal conductivity is an important criterion for judging the performance of aluminium pcb board. Aluminum pcb are also divided according to thermal conductivity, into ordinary thermal conductivity, middle thermal conductivity, and high thermal conductivity. Commonly used aluminum substrate pcb thermal conductivity is 1.0W/m.k to 3.0W/m.k,

4. Surface treatment:

There are many kinds of surface treatment of PCB. The most commonly used surface treatment methods for aluminum substrates are OSP, HASL and LF-HASL. To learn more about surface treatment, please refer to our surface treatment blog.

What Are The Advantages Of Aluminum PCBs?

1. Lower cost:To achieve the same heat dissipation performance, aluminum PCB is often the best choice. It is far cheaper than other metal substrate such as copper base PCB.

2.Light weight: Aluminum is a surprisingly lightweight metal due to its incredible durability. Aluminum adds strength and resilience without adding extra weight. This is why it is widely used.

3. Better heat dissipation performance: High temperatures can severely damage electronics or LED lights. Aluminum PCBs transfer heat better and reduce thermal wear on all components, making your device more durable. Aluminum can actually transfer heat away from vital components, minimizing the harmful effects it can have on the board. Typically, aluminum PCBs transfer heat 8 to 9 times faster than PCBs made with FR-4.

4. Higher durability:Aluminum provides products with strength and durability that FR-4 or CEM1 cannot provide. Aluminum is a strong base material that can reduce accidental breakage during manufacturing process and daily use.

5.Dimensional stability: As environmental conditions change, especially in high temperature environments. The size of the MCPCB is more stable than the PCB made of FR-4, or CEM1, and it is not prone to some board edge bending problems. After a heating process from 30°C to approximately 150°C, the dimensional change of the aluminum PCB is very small, ranging roughly between 2.5% and 3.0%.

Of course, if your electronics generate a lot of heat during work. And you don’t want to compromise the durability and performance of your product for that reason. Then we still recommend using high TG PCB. It has excellent heat resistance and dimensional stability.

6.Environmentally friendly:Aluminum is non-toxic and recyclable. Therefore, the use of this aluminum PCB helps maintain the health of our earth.

How To Choose Good Quality Aluminum PCB?

Thermal Conductivity:

The thermal conductivity of the aluminum substrate is the heat dissipation performance parameters of the aluminum substrate. Thermal conductivity refers to the heat transfer through 1 square meter area in 1 second with a temperature difference of 1 degree (℃) on both sides of a material with a thickness of 1 m under stable heat transfer conditions, and the unit is Watts/meter degrees (W/(m K),

The common thermal conductivity of aluminum substrates is 1.0, 1.5, 2.0, 3.0 W/m.k. The aluminum PCB manufactured by JHDPCB can reach up to 10W/m.k after testing, and can be used in products with a total power of 1000W when used together with a heat sink.

Comparative Tracking Index (CTI):

The highest voltage value at which the surface of the material can withstand 50 drops of electrolyte (0.1% ammonium chloride aqueous solution) without forming leakage traces, in V. JHDPCB can produce aluminum PCB with CTI>600.

If the use environment of aluminum PCB is humid, consider choosing PCB with CTI>600. JHDPCB has produced several PCB cases with CTI600 for customers.

Peel Strength:

Peel Strength means the force required to peel a conductor or foil from a substrate. Usually we test them according to IPC-TM-650 criteria.

Trace to Laminate>9 lb/in (Normal Tg Material)

Trace to Laminate 6 lb/in (High Tg Material)

Layer to Layer>4 lb/in

Heat resistance:

The heat resistance of the PCB mainly adopts the immersion tin method or the float tin method. The method is to set the tin furnace at about 285 degrees Celsius, immerse the aluminum substrate in the tin furnace, take it out after 10S, and observe the phenomenon of layering and foaming after cooling. Our aluminum-based PCB will easily help you control the heat generated by the required equipment, reduce the cost of PCB size and enable you to have a reliable high-performance PCB.

Breakdown Voltage:

In order to prevent lightning strikes, some outdoor products require aluminum substrates to have higher withstand voltage values. High Pot. Test is a commonly used test method. Please refer to our blog for details on how to test the withstand voltage of a PCB.

Why Is The Aluminum Substrate PCB Not Short-Circuited?

Aluminum PCB is a metal core PCB that conducts electricity, so there are concerns that aluminum substrates are prone to short circuits. As a professional aluminum pcb manufacturer, JHDPCB can tell you responsibly that if the circuit design is reasonable and the PCB manufacturing is error-free, the aluminum substrate will not be short-circuited. Because the aluminum substrate has an insulating layer, which is also a thermal conductive layer. It is possible to separate the aluminum-based and copper circuits, and only conduct heat from the circuits to the aluminum substrate, but not conduct electricity. If you have no confidence in your PCB design drawings, you can send the relevant documents to our professional engineers. We will provide a free file check to ensure the normal working of the PCB.

What Is Black Aluminum PCB?

Black aluminum board is an aluminum substrate pcb with black solder mask ink, usually with bright black solder mask, or matte black solder mask. Black solder mask is usually used on some optical products that require the PCB to be non-reflective. Black solder mask ink is easily scratched during production and transportation, resulting in poor appearance. JHDPCB has passed countless ink tests and can produce black solder mask that is not easy to scratch the surface.

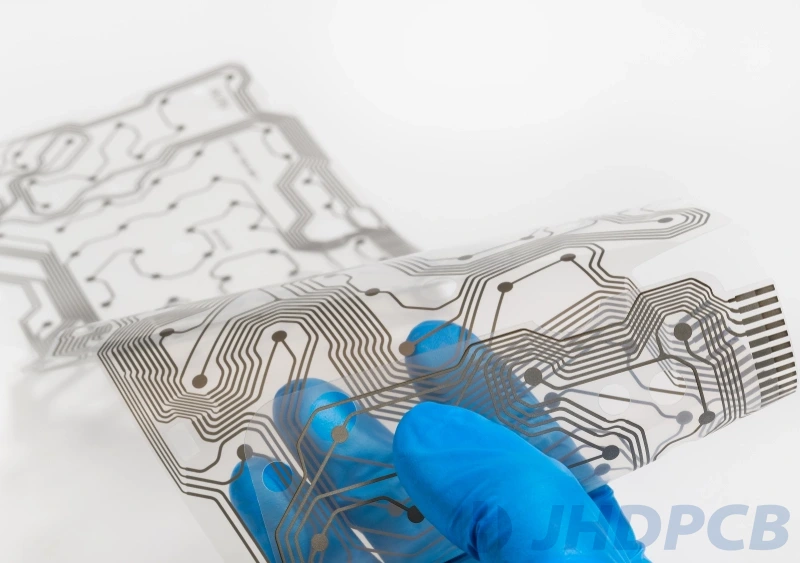

What Are The Types Of Aluminum PCB?

- Aluminum substrates can be divided into: flexible aluminum PCBs, rigid aluminum PCBs, hybrid aluminum PCBs (two or more layers of FR-4 boards are fused to aluminum substrates using thermodielectric materials).

- According to the number of layers, aluminum PCB is divided into single-sided aluminum PCB, double-sided aluminum PCB, and multi-layer aluminum PCB.

- According to the thermal conductivity, aluminum PCB is divided into ordinary thermal conductivity aluminum circuit board, middle thermal conductivity aluminum circuit board, high thermal conductivity aluminum circuit board.

- According to the thickness of copper, aluminum PCB is divided into standard copper thick aluminum PCB, heavy copper aluminum PCB.

- According to solder mask color, aluminum PCB is divided into white aluminum base pcb, milky white aluminum base pcb, black aluminum base pcb, green aluminum base pcb.

Where Are Aluminum PCBs Produced?

Since aluminum PCB production will produce metal pollution, many countries or cities have banned the production of aluminum PCBs. But China still allows the production of aluminum PCBs due to its good metal wastewater treatment technology. And it is the largest aluminum PCB fabrication country in the world. As one of the top 5 aluminum PCB manufacturers in China, JHDPCB strictly abides by relevant environmental laws and regulations.