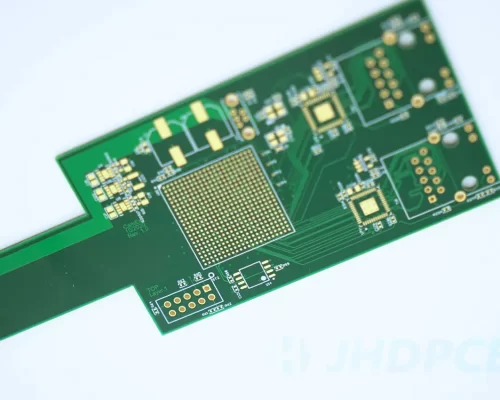

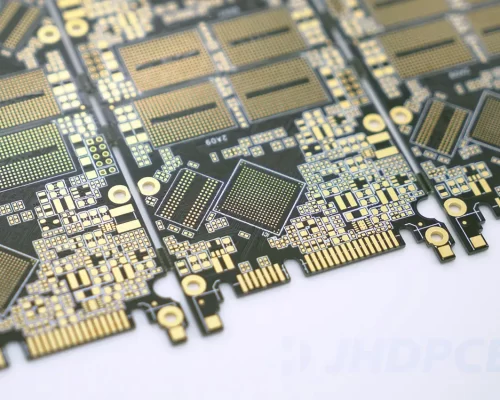

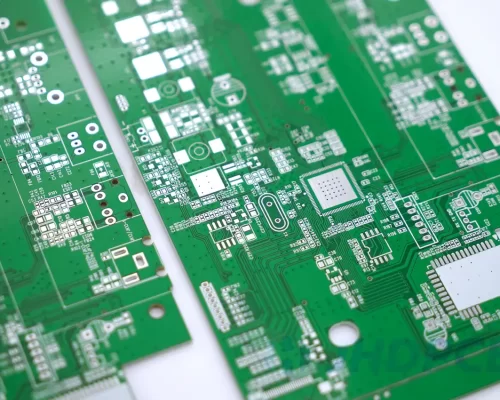

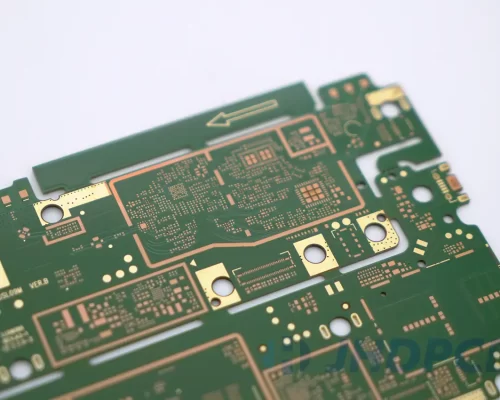

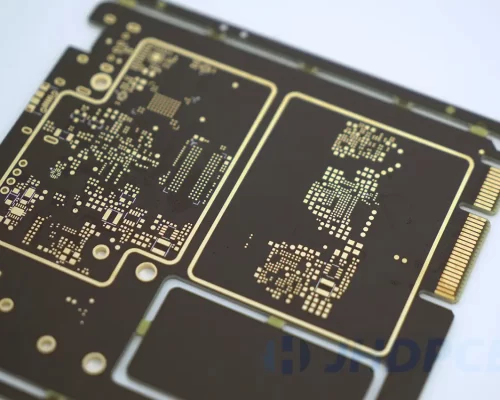

HF Communication PCB manufacturing

HF Communication Industry PCB Market Size and Prospects:

In the dynamic realm of High-Frequency (HF) Communication, the market for Printed Circuit Boards (PCBs) is witnessing robust growth. This surge is propelled by the escalating demand for high-performance communication systems, notably fueled by the adoption of HF technologies such as RFID, NFC, and advanced wireless communication protocols. The main areas involved include the following points:

- 5G network: Today, 5G networks around the world have been widely used. High-speed signals and low latency enable more people to use them. The extensive construction and promotion of 5G networks is the main driving force for the prospects of PCB in the high-frequency communication industry.

- Development of the Internet: With the development of the Internet of Things, equipment in smart homes, smart cities, industrial Internet of Things and other fields require high-frequency communication to achieve interconnection. Therefore, it provides a broad market demand for high-frequency communication PCB.

- The rise of smart devices: High-performance, miniaturized PCBs are now widely used in smart devices such as smartphones, smart wearable devices, and smart home appliances, enabling them to increase the smart demand for these devices.

- Growth in the fields of satellite communications and aerospace: The fields of satellite communications, satellite navigation and aerospace are now one of the hot spots in the world. In these fields, more and more precise PCB use is required to ensure their normal operation.

- Integration of RF front-end modules: RF front-end modules in high-frequency communication equipment are allowing it to integrate more functions on a PCB, helping to reduce the size of the equipment and improve system performance. This will promote the development prospects of high-performance PCB.

As the world embraces the Internet of Things (IoT) and Industry 4.0, the HF Communication PCB market is poised for substantial expansion. The future holds promising opportunities for innovative PCB solutions that can meet the stringent demands of high-frequency applications, reflecting a flourishing market landscape.

The Role Of PCBs In The HF communication Industry, New Technologies And New Industry-Specific Needs Challenges:

In the field of high-frequency communications, Printed Circuit Board (PCB) has important applications. In high-frequency communications, PCB design and material selection are crucial for signal transmission, impedance matching, and electromagnetic compatibility.

The role of PCB in high-frequency communications:

In the high-frequency communication industry, PCBs play a key role in providing reliable electrical connections and signal transmission for high-frequency communication equipment. Radio frequency and microwave circuit structures can be constructed to ensure efficient communication between communication components and transmit high-frequency signals.

New technology for High-frequency communication PCB:

As high-frequency technology advances, a new generation of PCBs is emerging, leveraging advanced materials and manufacturing techniques to meet the demands of higher frequencies, higher data throughput, and lower signal-to-noise ratios. PCBs can be continuously developed to meet the new challenges brought by high-frequency communications by combining innovative methods such as low-loss high-dielectric constant high-frequency materials, microstrip line technology, and advanced three-dimensional packaging technology.

Industry-specific Challenges:

Designing PCBs for HF communications presents a unique set of challenges during development. The transmission of high-frequency signals is susceptible to signal attenuation and interference, so electromagnetic compatibility (EMC), signal integrity, and power loss need to be considered. Signal integrity, temperature stability and maintaining matched impedances also require attention. In addition, the demand for miniaturization and high density drives innovation in PCB technology to accommodate compact designs for high-frequency devices.

The application of circuit boards in HF communication:

- Radio Frequency and Microwave Circuits: In radio frequency (RF) and microwave circuits, where the signal transmission speed and wavelength are typically higher, the PCB provides impedance matching, signal integrity, and the characteristic impedance of the transmission line.

- Antenna design: Antennas in high-frequency communications are usually integrated on the PCB. PCB material and design affect antenna performance (such as gain, directivity).

- Communication equipment: High-frequency communication equipment, such as radio frequency modules, communication base stations, etc., usually use PCB as a support structure, which directly affects the overall performance and stability of the equipment.

- Wireless communication module: In wireless communication module, PCB is used to connect and support various components, such as radio frequency integrated circuits, antennas, filters, etc.

- Microstrip and waveguide designs: Microstrip and waveguides on PCBs are used to transmit signals in the high frequency range.

- 5G Equipment: 5G communication technology uses millimeter wave frequency bands. 5G antenna arrays, radio frequency front-end modules and other parts require PCB to support and connect.

Development Trends of PCBs in the HF Communication Industry:

The development trend of PCB in the high-frequency communication industry is mainly affected by emerging technologies and market demand. The following are some trends in PCB development in the high-frequency communication industry:

- Promoted by 5G technology: The construction and popularization of global 5G networks has significantly increased the demand for high-frequency PCBs. 5G communication involves millimeter wave frequency bands, requiring PCBs to have higher performance and precision to support high-speed data transmission and low-latency communications.

- Integration of RF front-end modules: The future trend is for more RF front-end modules to be integrated on the PCB, which requires higher performance on the PCB to achieve a more compact and lightweight design.

- Antenna design innovation: Antennas are a vital component in high-frequency communications. PCB developments include more innovative antenna designs, such as multi-antenna technology and beamforming technology, to improve communication efficiency and coverage.

- High integration and miniaturization: The future trend of high-frequency communication PCBs will emphasize achieving higher levels of integration and miniaturization. In order to meet the needs of embedded high-frequency communication equipment, PCB will assume the role of integrating more various radio frequency and communication components, thereby achieving more compact and lightweight equipment design. All while maintaining excellent performance.

- Intelligence and IoT applications: As IoT devices are widely used in high-frequency communications, PCBs will support efficient communication between more smart sensors, communication modules and devices to meet the development needs of the IoT. The demand for low power consumption and high efficiency will drive further innovation in PCB technology in the high-frequency communications industry.

- Sustainability and environmental protection: Sustainability and environmental protection issues in PCB manufacturing are also a development trend. In the future, the manufacturing of high-frequency PCBs may pay more attention to the use of environmentally friendly materials and processes.

Generally speaking, the development trend of PCB in the high-frequency communication industry is mainly reflected in higher performance requirements, the application of new technologies, improvements in miniaturization and integration, and concerns about sustainability. In the ever-evolving field of high-frequency communications, JHDPCB will closely track technology developments, flexibly adapt to new industry needs, and provide highly customized solutions to promote progress in the communications field.

HF COMMUNICATION PCB Application.

- 5G communication equipment

- RF front-end module

- Communication base station

- Smart phone

- Smart Appliances

- Router

- Fixed broadband

- Communication network

- Communication satellite

- Aerospace electronic equipment

- Wireless communication module

- High frequency radar system

- Millimeter wave communication equipment

- Radio Frequency Identification (RFID) Systems

- Medical device sensors

- Automated industry

- Vehicle communication system

- IoT devices

- Military communications equipment

- RF test and measurement equipment

- Television and satellite broadcasting equipment

- Environmental monitoring sensors

Why Choose JHD HF communication PCB

Compared with traditional circuit boards, photovoltaic circuit boards have the following advantages:

- High performance material selection

- Precision manufacturing process

- Multi-layer design

- Good impedance matching

- High reliability

- Flexibility

HF PCB (High Frequency Printed Circuit Board) plays a vital role in high-frequency communications. Its role is mainly reflected in the following aspects:

- Signal transmission: HF PCB ensures that signals can be transmitted at high speed, low delay and low distortion through precise design and manufacturing.

- Impedance matching: HF PCB can precisely control the geometry and materials of transmission lines to ensure impedance matching with other circuit components, reduce signal reflection and loss, thereby improving system performance and stability.

- Electromagnetic compatibility: The design of HF PCB can reduce electromagnetic radiation and interference, ensure that devices do not interfere with each other, and improve the stability and reliability of the system.

- Support high-frequency components: HF PCB provides stable electrical connections and guidance to ensure that high-frequency components can work and communicate properly.

- Microstrip and waveguide design: Microstrip and waveguide are designed on HF PCB to ensure stable signal transmission.

In summary, HF PCB plays a key role in high-frequency communication, supporting signal transmission, impedance matching, electromagnetic compatibility, etc., and is an indispensable component of high-frequency communication equipment.

- PTFE (Polytetrafluoroethylene): They are commonly used in RF and microwave applications due to their low loss characteristics.

- Rogers RO4000 Series: Rogers Corporation offers a range of high-frequency laminates under the RO4000 series, known for their stable electrical performance, low loss, and excellent dimensional stability.

- Isola FR408HR: Isola FR408HR is a high-performance FR-4 epoxy laminate with a low dielectric constant and low loss tangent at high frequencies. It offers good signal integrity and is suitable for high-speed digita

- Arlon AD Series: Arlon AD series laminates are designed for high-frequency applications and offer excellent electrical performance, low loss, and good thermal stability.

- Nelco N4000-13EP: Nelco N4000-13EP is a high-performance laminate with a low dielectric constant and low loss tangent, specifically designed for high-frequency applications.

- Duroid 5880: Duroid 5880 is commonly used in RF and microwave applications where low loss and high signal integrity are critical.

As a company specializing in electronic design and manufacturing, JHD has rich experience and expertise, and has the ability to produce high-frequency communication PCB designs. The following are the key capabilities JHD possesses:

- Professional team: JHD has a professional engineering team. The engineers have profound experience in electronic design and manufacturing and are familiar with the relevant technologies and specifications of high-frequency communication PCB design.

- Advanced equipment: JHD is equipped with advanced PCB design software and manufacturing equipment, which can meet the requirements of high-frequency communication PCB design.

- Material selection: JHD is able to select appropriate high-frequency materials, such as polytetrafluoroethylene (PTFE), etc., according to design requirements to ensure good signal transmission and impedance matching.

- Strict quality control: JHD implements a strict quality control system, and every link from design to manufacturing undergoes strict inspection and testing to ensure the quality and stability of high-frequency communication PCBs.

- Customized services: JHD can provide customized high-frequency communication PCB design services according to customer needs.

JHD is committed to providing excellent PCB design and manufacturing solutions for the high-frequency communication field and is confident in our capabilities and experience. We have a professional engineering team and advanced manufacturing equipment to meet our customers’ strict requirements for high performance, stability and reliability. JHD will wholeheartedly provide customers with high-quality customized services and provide all-round support and cooperation for the successful realization of the project. We firmly believe that through cooperation with JHD, you will obtain satisfactory high-frequency communication PCB solutions. Looking forward to working with you to create a better future!

JHD HF communication PCB