Mobile energy storage PCB manufacturing

Market size and prospects of PCB in mobile energy storage industry.

In the mobile energy storage industry, PCBs are widely used in devices such as battery management systems (BMS) and chargers to ensure their safe, stable and efficient operation. Mobile energy storage technologies include electric vehicles (EV), hybrid electric vehicles (HEV), rechargeable energy storage devices (such as portable chargers, power banks, etc.), etc. According to a market research report, the global electric vehicle market is expanding rapidly and is expected to reach $2.7 trillion by 2028.

With the continuous improvement of environmental awareness and the government’s strong support for clean energy, the electric vehicle market will have more opportunities and room for development. In addition, with the increasing demand for mobile devices, the market for products such as portable chargers and power banks is also growing rapidly. Therefore, the market prospect of the mobile energy storage industry is very broad and will continue to maintain rapid growth.

In such a fast-growing market, JHDPCB can meet the needs of customers by providing high-quality, high-reliability PCB products, and provide customers with better product performance and longer service life.

The role of PCB in the mobile energy storage industry, new technologies and new challenges.

Mobile energy storage is a field that has developed rapidly in recent years, and it is also an important driving force for the development of industries such as electric vehicles and drones. In mobile energy storage systems, PCB is an indispensable component, which can connect and control various batteries and electronic devices to ensure the normal operation and stability of the system.

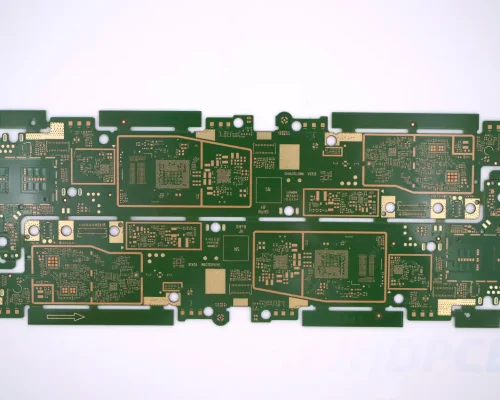

With the continuous expansion of the mobile energy storage market, the demand for PCBs is becoming more and more diverse and demanding. On the one hand, mobile energy storage systems require higher power and smaller volume batteries and controllers, which requires PCB design and manufacturing technology to meet higher circuit density and thermal management requirements. On the other hand, in order to meet the efficiency requirements of energy conversion and energy conservation requirements, mobile energy storage systems require more advanced power management technology, which also requires PCBs to provide higher precision and more complex circuit layout and wiring.

In recent years, with the rapid development of new energy vehicles, drones, aerospace and other fields, the prospect of the mobile energy storage market is very broad. At the same time, with the continuous advancement and upgrading of electronic equipment and battery technology, the technical and service requirements for PCB manufacturers will also become higher and higher. Therefore, PCB manufacturers need to continuously improve their own technology and service levels, and develop more advanced PCB design and manufacturing technologies to meet the continuous upgrading and development needs of mobile energy storage systems.

Development trend of PCB in the mobile energy storage industry.

PCBs are used in a wide range of applications in the mobile energy storage industry, involving products such as battery management systems (BMS), electric vehicles, wearable devices, smartphones, and tablets. The development of PCB is closely related to mobile energy storage technology. With the development and application of new energy technology, the market scale and prospects of mobile energy storage industry are becoming increasingly broad.

In terms of the development trend of PCB, there are mainly the following points:

- Green environmental protection

With the continuous improvement of environmental protection awareness, green and environmentally friendly PCBs have become the mainstream trend in the market. This type of PCB uses environmentally friendly materials, such as lead-free materials, organic solvents, and water-based spraying, to reduce the impact on the environment. - Ultra thin plate

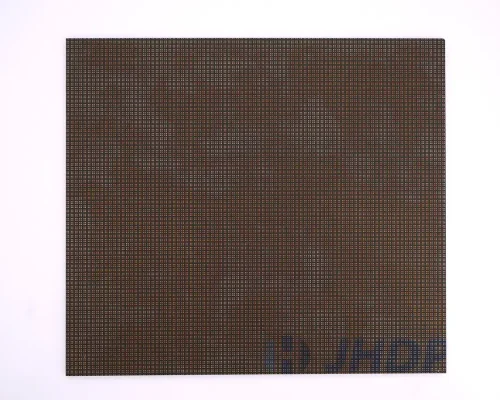

Mobile energy storage products are becoming thinner and lighter, so thinner PCBs are required. The manufacture of ultra-thin PCBs is a challenge for PCB manufacturers, but ultra-thin PCBs also bring more application space for the mobile energy storage industry. - HDI PCB

High-density PCB can reduce the size of the product and improve the performance of the product. With the rapid development of the mobile energy storage industry, the demand for high-density PCBs is also increasing. - Flexible PCB

Flexible PCBs are suitable for bending and folding in mobile energy storage products, so they are widely used in wearable devices, smartphones and other products. With the continuous upgrading of these products, the demand for flexible PCB is also increasing.

In the mobile energy storage industry, JHDPCB has rich experience and a professional technical team, which can provide customers with high-quality PCB manufacturing services. We are committed to providing customers with the most advanced PCB manufacturing technology and the best quality service to help customers succeed in the mobile energy storage industry. If you need quality PCB manufacturing services, please contact us.

Mobile energy storage products with PCB application.

- Electric/hybrid cars;

- Charging pile;

- Electric bicycles/motorcycles;

- Power bank/charging treasure;

- Solar power charger;

- Unmanned aerial vehicles;

- Smart bracelet/watch;

- Wireless Headphones;

- Wireless charger;

- Smart Glasses;

- Portable wireless speakers;

- Electric Scooter;

- E-cigarette;

- Electronic oxygen inhaler;

- Portable medical devices;

Why Choose JHD Mobile Energy Storage PCB

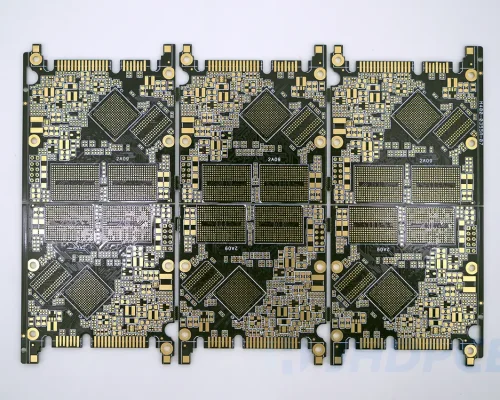

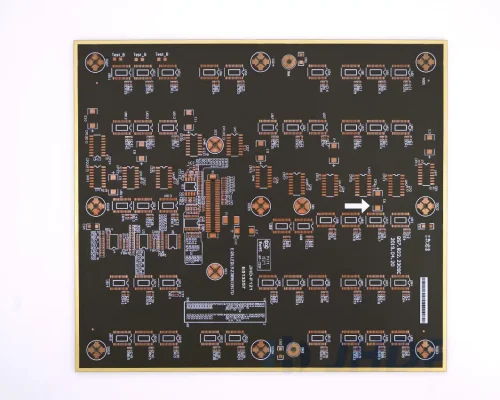

JHDPCB has the ability to review DFM and DFA designs in the early stage to avoid cost waste caused by design defects. Capability to manufacture high density, high performance PCBs. This involves mastering the design and manufacturing techniques of multi-layer boards and high-speed boards, as well as knowledge and experience in PCB material selection, wiring, layout and impedance control. In addition, we also understand the characteristics and requirements of batteries in mobile energy storage devices and develop suitable manufacturing solutions accordingly.

Secondly, JHD also grasps that mobile energy storage PCB manufacturing needs to ensure quality and comply with relevant certifications and standards. For example:

- ISO9001;

- RoHS certification;

- UL standard;

- IPC class 2&3 specifications;

- Material specification;

- J-STD-001 ES;

We (JHDPCB) have many years of experience and technology accumulation in PCB manufacturing, and can provide high-quality mobile energy storage PCB manufacturing services. We have advanced manufacturing equipment and quality management system, which can ensure the quality of each PCB and meet the relevant standards and certification requirements. Our services cover PCB design, manufacturing, assembly and testing, and can provide customers with one-stop PCB manufacturing solutions.

In terms of mobile energy storage PCB manufacturing, our goal is to continuously improve technology and service levels to provide customers with the best PCB solutions. If you need PCB manufacturing services, please contact us, we will serve you wholeheartedly.

JHD mobile energy storage PCB