JHDPCB Technical Capabilities

| Features | Capability | Annotation | Patterns |

|---|---|---|---|

| Layer count | 1,2,4,6,8,10,12,14,16,18,20 layers | The number of copper layers in the board. | |

| Controlled Impedance | 4/6 layer, default layer stack-up | Controlled Impedance PCB Layer Stackup | |

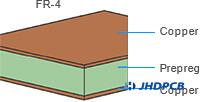

| Material | FR-4 | FR-4 Standard Tg 130-140/ Tg 155 |

|

| Dielectric constant | 4.5(double-sided PCB) | 7628 Prepreg 4.6 2313 Prepreg 4.05 2116 Prepreg 4.25 | |

| Max. Dimension | 400x500mm | The maximum dimension JLCPCB can accept |  |

| Dimension Tolerance | ±0.2mm | ±0.2mm for CNC routing, and ±0.4mm for V-scoring | |

| Board Thickness | 0.4/0.6/0.8/1.0/1.2/1.6/2.0mm | The thickness of finished board. |  |

Thickness Tolerance ( Thickness≥1.0mm) | ± 10% | e.g. For the 1.6mm board thickness, the finished board thickness ranges from 1.44mm(T-1.6×10%) to 1.76mm(T+1.6×10%) | |

Thickness Tolerance ( Thickness<1.0mm) | ± 0.1mm | e.g. For the 0.8mm board thickness, the finished board thickness ranges from 0.7mm(T-0.1) to 0.9mm(T+0.1). | |

| Finished Outer Layer Copper | 1 oz/2 oz (35um/70um) | Finished copper weight of outer layer is 1oz or 2oz. |  |

| Finished Inner Layer Copper | 0.5 oz (17.5um) | Finished copper weight of inner layer is 0.5oz by default. |  |

| Features | Capability | Notes | Patterns |

|---|---|---|---|

| Drill Hole Size | 0.20mm- 6.30mm |

Min. drill size is 0.20mm. Max. drill size is 6.30mm. |

|

| Drill Hole Size Tolerance | +0.13/-0.08mm | e.g. for the 0.6mm hole size, the finished hole size between 0.52mm to 0.73mm is acceptable. | |

| Blind/Buried Vias | Don’t support | Currently we don’t support Blind/Buried Vias, only make through holes. |  |

| Min. Via hole size | 0.2mm | For Single&Double Layer PCB, the minimum via hole size is 0.3mm;For Multi Layer PCB, the minimum via hole size is 0.2mm |  |

| Min. Via diameter | 0.4mm | For Single&Double Layer PCB, the minimum Via diameter is 0.6mm;For Multi Layer PCB, the minimum via diameter is 0.4mm. |  |

| PTH hole Size | 0.20mm – 6.35mm | The annular ring size will be enlarged to 0.15mm in production. |  |

| Pad Size | 0.70mm- 6.35mm | The pad hole size will be enlarged 0.15mm in production. |  |

| Min. Non-plated holes | 0.50mm | The minimum NPTH dimension is 0.50mm, Please add the NPTH in the mechanical layer or keep out layer. |  |

| Min. Plated Slots | 0.65mm | The minimum plated slot width is 0.65mm, which is drawn with a pad. |  |

| Min. Non-Plated Slots | 1.0mm | The minimum Non-Plated Slot Width is 1.0mm, please draw the slot outline in the mechanical layer(GML or GKO) |  |

| Min. Castellated Holes | 0.60mm | The minimum diameter of castellated holes is 0.60mm. |  |

| Hole size Tolerance (Plated) | +0.13mm/-0.08mm | e.g. for the 1.00mm Plated hole, the finished hole size between 0.92mm to 1.13mm is acceptable. |  |

| Hole size Tolerance (Non-Plated) | ±0.2mm | e.g. for the 1.00mm Non-Plated hole, the finished hole size between 0.80mm to 1.20mm is acceptable. |  |

| Rectangle Hole/Slot | Don’t support | We don’t make rectangle hole/slot,the rectangle hole/slot will be made as round or oval hole/slot by default. |  |

| Minimum annular ring | PTH | Patterns | |

|---|---|---|---|

| 1oz Copper | 0.13mm | 0.3mm |  |

| 2oz Copper | 0.2mm | 0.3mm |

| Features | Capabilities | Patterns |

|---|---|---|

| Hole to hole clearance(Different nets) | 0.5mm |  |

| Via to Via clearance(Same nets) | 0.254mm |  |

| Pad to Pad clearance(Pad without hole, Different nets) | 0.127mm |  |

| Pad to Pad clearance(Pad with hole, Different nets) | 0.5mm |  |

| Via to Track | 0.254mm |  |

| PTH to Track | 0.33mm |  |

| NPTH to Track | 0.254mm |  |

| Pad to Track | 0.2mm |  |

| Min. Trace width | Min. Spacing | Patterns | |

|---|---|---|---|

| 1-2 Layers | 5mil (0.127mm) | 5mil (0.127mm) |  |

| 4-6 Layers | 3.5mil (0.09mm) | 3.5mil (0.09mm) | |

| 2oz Copper weight | 8mil (0.2mm) | 8mil (0.2mm) |

| Layer count | Min. BGA Pad Dimensions | Min. Distance Between BGA | Patterns |

|---|---|---|---|

| 1/2 layers | 0.4 mm | 0.127mm |  |

| 4/6 layers | 0.25 mm | 0.127mm |

| Features | Capabilities | Notes | Patterns |

|---|---|---|---|

| Solder mask opening/ expansion | 0.05mm | The solder mask should have a minimum of a 0.05 mm “growth/mask opening” around the pad to allow for any mis-registration. |  |

| Solder bridge |

0.2mm(green) 0.254mm(other colors) |

To have solder mask bridge, the spacing between copper pads edge must be 0.2mm (8mils) or more. |  |

| Solder mask color | green, red, yellow, blue, white, and black. | We use LPI (Liquid Photo Imageable) solder mask. It is the most common type of mask used today. | |

| Solder mask dielectric constant | 3.8 | ||

| Solder mask thickness | 10-15UM |

| Features | Capabilities | Notes | Patterns |

|---|---|---|---|

| Minimum Line Width | 6 mil (0.153mm) | Characters width less than 6mil(0.153mm) will be unidentifiable. |  |

| Minimum text height | 40 mil (1.0mm) | Characters height less than 40 mil(1.0mm) will be unidentifiable. |  |

| Character width to height ratio | 1:6 | The preferred ratio of width to height is 1:6. |  |

| Pad To Silkscreen | 0.15mm | The Minimum Distance Between Pad and Silkscreen is 0.15mm. |  |

| Features | Capabilities | Notes | Patterns |

|---|---|---|---|

| Trace to Outline | 0.2mm | Ships as individual board(Rounting):Trace to Outline≥0.2mm |  |

| Trace to V-cut line | 0.4mm | Ship as panel with V-scoring: Trace to V-cut line≥0.4mm |  |

| Features | Capabilities | Notes | Patterns |

|---|---|---|---|

| Panelization without space | 0mm | The space between boards is 0mm. |  |

| Panelization with space | 2mm | Make sure the space between boards should be ≥2mm,otherwise it will be hard to process for rounding. |  |

| Panelized Round board | ≥20mmx20mm |

The single round board size should be≥20mmx20mm. Panelize with stamp holes and add tooling strips on four board edges |

|

| Panelized castellated holes board | Panelize with stamp holes and add tooling strips on four board edges |

The distance between castellated hole and board corner should be larger than 3mm. Recommended diameter of stamp hole is 0.5mm-0.8mm; Recommended distance between the two stamp holes is 0.2-0.3mm |

|

| Min. Width of Breakaway Tab | 4mm | The minimum width of breakaway tab is 4mm. For breakaway with mouse-bites, the minimum width is 5mm. |  |

| Min. Edge Rails | 3mm | If choosing panel by JLCPCB, we will add 5mm edge rails on both sides by default. |  |