Photovoltaic PCB manufacturing

The role of PCBs in the photovoltaic industry, new technologies and new industry-specific needs challenges:

In the dynamic landscape of the photovoltaic (PV) industry, Printed Circuit Boards (PCBs) play a pivotal role in ensuring the seamless integration and optimal performance of solar power systems. The intricate network of PCBs within solar inverters and charge controllers facilitates efficient energy conversion and management. As the PV sector embraces advancements, new technologies emerge, bringing both opportunities and challenges.

Role of PCBs in the Photovoltaic Industry: PCBs serve as the backbone, connecting solar panels to inverters and storage systems. The robustness and reliability of PCBs are paramount in handling the unique demands of solar applications, providing a stable platform for energy harvesting and distribution.

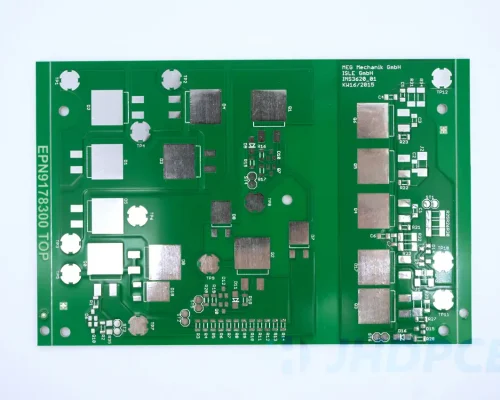

New Technologies in Photovoltaic PCBs: In response to the evolving needs of the PV industry, cutting-edge technologies are enhancing PCB design. High-temperature-resistant materials, advanced copper thicknesses, and innovative layer configurations are optimizing PCBs for the harsh environmental conditions often associated with solar installations.

Industry-Specific Challenges: As the PV sector matures, so do its challenges. PCBs must contend with increased power densities, temperature variations, and stringent durability requirements. Addressing these industry-specific challenges involves a delicate balance of material selection, design considerations, and adherence to evolving standards.

PCB development trends in the photovoltaic industry:

- Integration of Smart Technologies: The future of PCBs in the photovoltaic sector is marked by the integration of smart technologies. Smart inverters and monitoring systems, driven by sophisticated PCB designs, enable real-time data analysis, predictive maintenance, and enhanced overall system performance.

- Focus on Sustainability: In line with the broader sustainability goals of the PV industry, there is a growing emphasis on eco-friendly PCB materials and manufacturing processes. The trend is towards developing PCBs that not only meet performance criteria but also align with the environmental consciousness of the solar energy sector.

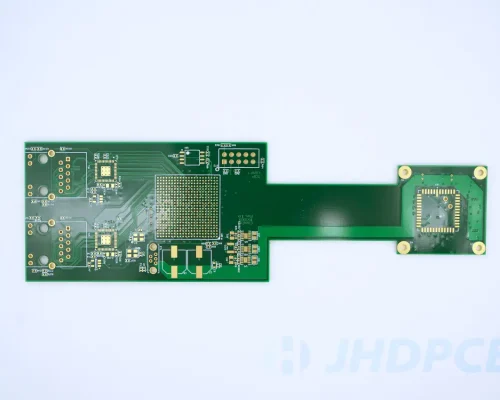

- Increased Customization and Flexibility: As the photovoltaic landscape diversifies, there is a notable trend towards customized PCB solutions. Tailoring PCB designs to specific solar applications ensures optimal efficiency and reliability. Flexible PCBs, in particular, are gaining prominence for their adaptability to the varying form factors of solar installations.

- Advancements in Energy Storage Integration: With an increasing focus on energy storage solutions, PCBs in the PV industry are evolving to support seamless integration with batteries and energy storage systems. This trend reflects the industry’s commitment to enhancing energy independence and grid resilience.

In navigating the future of PCBs within the photovoltaic sector, staying attuned to these trends is essential. The synergy between PCB technology and solar innovation will continue to define the efficiency, reliability, and sustainability of solar power systems.

Application of circuit boards in photovoltaic

Photovoltaic power generation (PV) is the use of semiconductor materials with photovoltaic effect to convert light into electrical energy. The photovoltaic effect is a phenomenon studied in the fields of physics, photochemistry and electrochemistry. The photovoltaic inverter converts the direct current generated by the solar panels into alternating current and is the core component of the photovoltaic power generation system. Now let’s talk about the application of circuit boards in photovoltaic:

- Connect photovoltaic battery: The circuit board connects the wires on the photovoltaic cell board to the photovoltaic panel main control board, so that the photovoltaic cells can convert solar energy into direct current.

- Battery management: The circuit board is connected to the battery management system to monitor the status of the battery and ensure the normal operation of the battery. Through the circuit board, the battery can work together with photovoltaic panels and inverters to achieve efficient power conversion.

- Control the inverter: The inverter PCB control board is an important part of the photovoltaic inverter, which directly affects the performance and stability of the photovoltaic inverter. Control it to convert DC power into AC power, and outputs it to the grid.

The Development Prospect Of photovoltaic PCB Technology

With the increasing global emphasis on environmental protection, photovoltaic is widely used in various scenarios, The following will introduce the development prospect of photovoltaic technology:

- Home and Commercial Buildings:

Photovoltaic can be used to power homes, such as electric water heaters, air conditioners, lighting, etc. It also provide energy for lighting, air conditioning, elevators, etc. in commercial buildings. By using photovoltaic can lower your home’s electricity costs and greatly reduce a company’s electricity costs while also making a positive contribution to the environment. . - Transportation:

Photovoltaic can be used in the field of transportation, such as providing energy for electric vehicles, electric bicycles, etc. Photovoltaic can be quickly charged in places with sufficient sunlight so that they can be used for a longer period of time. - Wireless telecommunications systems:

In remote areas, such as mountains and deserts, where power systems are insufficient, photovoltaic technology can be used together with battery storage to provide renewable energy to meet the needs of wireless communication equipment. - Outdoor activities:

Photovoltaic technology can be used for outdoor activities such as camping, hiking, self-driving tours, etc. Photovoltaic technology can charge mobile phones, tablets, electronic watches and other electronic devices without much power, and can also meet some basic needs outdoors. - Agricultural application:

In the agricultural field is mainly reflected in irrigation systems and farming. The irrigation system uses solar photovoltaic panels to convert solar radiation energy into electrical energy, providing water for farmland and solving the problem of farmland irrigation. Farming uses solar photovoltaic panels to provide electricity for farming facilities to meet the power supply needs during the farming process.

As a PCB manufacturer, JHDPCB can provide a variety of PCB suitable for photovoltaic technology. We can satisfy customers through high-quality PCB manufacturing services, improve efficiency and product quality during the use of photovoltaic panels.

Photovoltaic products with PCB application.

- Photovoltaic inverter;

- Solar battery;

- Electric vehicle;

- Electric bicycle;

- Electric water heater;

- Solar street light;

- Optical cable communication system and maintenance station;

- Mobile communication base station;

- Broadcast;

- Military GPS power supply;

- Solar radio;

- Solar clock;

- Solar power bank;

- Solar Calculator;

- Marine monitoring equipment;

- Irrigation system;

Why Choose JHD Photovoltaic PCB:

- High temperature resistance

- Waterproof and dust-proof

- Relatively low cost

- Longer use time.

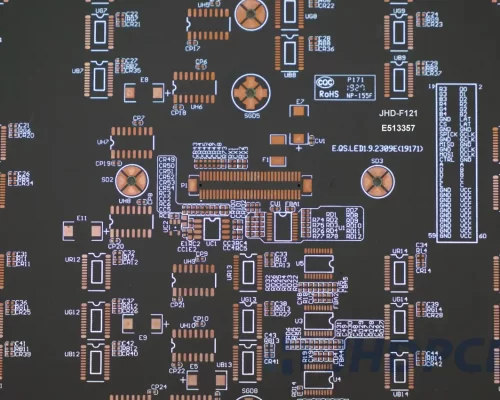

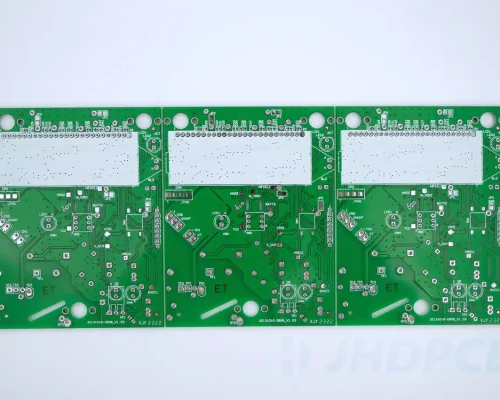

JHDPCB has the ability to review DFM and DFA designs in the early stage to avoid cost waste caused by design defects. Capability to manufacture high density, high performance PCBs. This involves mastering the design and manufacturing techniques of multi-layer boards and high-speed boards, as well as knowledge and experience in PCB material selection, wiring, layout and impedance control. In addition, we also understand the characteristics and requirements of batteries in mobile energy storage devices and develop suitable manufacturing solutions accordingly.

- Involve PCB suppliers in the design as early as possible;

- Consider the efficiency of photovoltaic panels;

- Confirm battery and panel size;

- Assess the need for power-dense modules;

- Consider firmware architecture;

- Implement simple current flow;

- Get the correct PCB component dimensions;

- Choose the right surface treatment(HASL is considered a standard surface treatment, but it tends to rub off the solder on photovoltaic PCB boards.)

- Properly space PCB component layout;

- Silicon: Silicon is one of the most commonly used materials for photovoltaic PCBs. It has good light absorption and conductive properties and can convert light energy into electrical energy.

- Glass substrate: As the outer protective layer of the solar panel, the glass substrate has good transparency and weather resistance. Therefore, many photovoltaic PCBs choose glass fiber reinforced polyimide resin, and some use polystyrene or polyester resin circuit boards.

- Metal foil: Metal foil is often used as a connecting material between solar cell chips and other components.

- Conductive silver paste: Conductive silver paste is used to connect photovoltaic cell chips and output lines. It has excellent conductivity and adhesion.

Secondly, JHD also grasps that mobile Photovoltaic PCB manufacturing needs to ensure quality and comply with relevant certifications and standards. For example:

- ISO9001;

- RoHS certification;

- UL standard;

- IPC class 2&3 specifications;

- Material specification;

- J-STD-001 ES;

Photovoltaic PCB is getting closer and closer to our lives, and many people are starting to use photovoltaic PCB. As an experienced PCB manufacturer, JHDPCB can help you solve various problems of photovoltaic PCB starting from the Gerber information. We can provide you with various services, from design to inspection, so that the photovoltaic PCB you require to be produced by JHDPCB will be perfect. If you have any needs, please contact us and we will provide you with high-quality services and excellent PCB.

JHD Photovoltaic PCB