FPC Stackup: An In-depth Look at Stackup Configurations

The world of electronics is always changing as new innovations emerge. Things like smartphones, computers, vehicles, and devices are getting smaller yet more powerful. Flexible printed circuit boards, also called flex boards or FPC boards, play an important role in powering many devices.

Flex boards are different from regular circuit boards because they are thin and can bend. This makes them useful for putting into electronics with curved shapes or unusual designs. For example, flex boards allow smartwatches to wrap comfortably around wrists. They can also be found in car parts that need to flex like airbags or brakes.

At JHDPCB, as a leader in custom flexible printed circuit board manufacturing. We design and produce high quality flex boards for clients around the world. If you require prototypes or mass production, our team is capable of transforming your project concepts into tangible products.

This article will delve into the details of flexible printed circuit board stackups, offering a comprehensive understanding of the topic. Things like layers, materials and configurations all impact a flex board’s performance. Understanding stackup options is important for engineers designing innovative new devices. We hope you find this information useful as you work on your next project. Please feel free to contact us if you have any other questions!

Now, let’s begin our discussion on flexible printed circuit board stackups and how their construction impacts design possibilities.

What Kinds of Stiffeners on the Flexible PCBs?

As the core material of PCB, the three main raw materials for the production of CCL include glass fiber cloth, epoxy resin and copper foil, and PCB relies on them to realize the functions of conduction, insulation and support. Among them, glass fiber cloth and epoxy resin are often used as prepregs.

There are instances where it becomes necessary to reinforce specific sections of a flexible circuit board or FPC with stiffeners. PCB stiffeners are utilized to add rigidity to certain areas of the board, making it easier to incorporate interconnects or solder components to these stiffer regions.

It’s important to note that PCB stiffeners do not serve as electrical components of the PCB. Instead, their purpose is to provide mechanical support to the printed circuit board during the assembly process. Additionally, PCB stiffeners offer benefits such as increased abrasion resistance, reinforcement of solder joints, and improved handling of the board for automated pick-and-place processes.

It should be acknowledged that utilizing stiffeners on a small panel can result in wastage of the square area. However, connector selection often necessitates this approach due to the limitations of certain connectors.

Polyamide (PI) Stiffeners, FR4 Stiffeners, and Stainless Steel Stiffeners are three commonly employed types of PCB stiffeners. These materials are particularly useful in projects that require enhanced stiffness and heat dissipation.

⑴ Polyamide (PI) Stiffener:

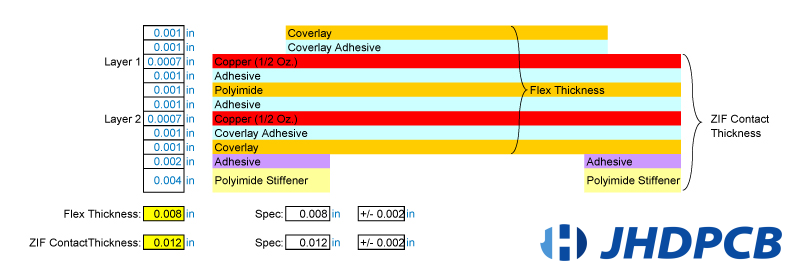

PI stiffeners serve as a cost-effective alternative to FR4. They are frequently employed to increase the thickness of the ZIF connector, ensuring proper contact and support. This allows for tolerance stackup in bending thickness and contours the component at the contact point.

In addition, PI stiffeners are utilized to limit the bending capability of certain areas on the PCB, ensuring they are well-prepared for final assembly. When wear becomes a concern, hole locations are reinforced with PI stiffeners to enhance wear resistance.

These stiffeners exhibit outstanding solder resistance and possess strong bond strength. They are typically applied to the backside of the insertion gold fingers, facilitating the insertion of flexible printed circuit connector fingers into ZIF sockets or connectors.

⑵ FR4 Stiffener:

FR4 is commonly used as the CCL (Copper Clad Laminate) for rigid printed circuit boards and is a popular material for PCB stiffener applications in flex circuits. The primary purposes of using FR4 stiffeners are:

➨ Providing sufficient support during pick-and-place and reflow processes for flexible PCBs to maintain flatness.

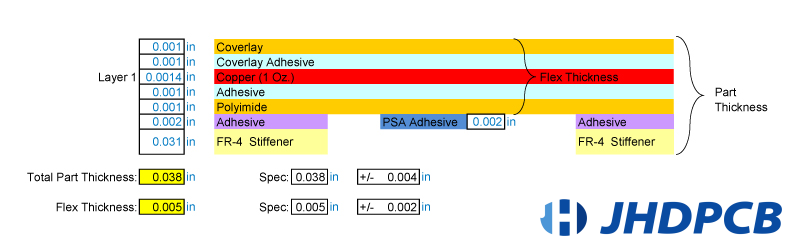

➨ By positioning the stiffeners on the same side of the flex PCB where the components are inserted, direct access to solder pads for plated-through hole (PTH) components is facilitated. In some cases, an FR4 frame can be added to the border of a panelized PCB to replace the more expensive SMT carrier, resulting in cost savings during the project assembly. The below image is one of the example of 2 layer pcb stackup or layer buildup with FR4 PCB stiffener.

⑶ Stainless Steel/Aluminum Stiffener:

Stainless steel or aluminum stiffeners are utilized in flexible circuit designs that necessitate attributes such as anti-corrosion resistance, robustness, formability, and capability. These stiffeners are usually added to the connecting fingers of flexible printed boards to strengthen them and facilitate assembly.

⑷ Using MultiLayer PCBs Stiffeners

When applying PCB stiffeners, manufacturers ensure that the stiffener overlaps the bored overlay by 0.030″ to alleviate stress. The overlay acts as a solder resistor for the flexible printed circuit board in this scenario.

Furthermore, it is also important if you maintain the same thickness for multiple stiffeners. Once the process is completed, the stiffeners enhance the strength of the solder joints by providing increased abrasion resistance.

FPC Stiffener Thicknesses

| Stiffener Material | Usual Thickness | Unusual Thickness |

|---|---|---|

| Polyimide (PI) | 0.05mm (2mil) 0.075mm (3mil) 0.1mm (4mil) 0.125mm (5mil) 0.15mm (6 mil) | 0.175mm (7mil) 0.2mm (8mil) 0.25mm (10mil) 0.225mm (9mil) 0.25mm (10mil) 0.275mm (11mil) |

| FR-4 | 0.2mm (8mil) 0.3mm (12mil) 0.4mm (16mil) 0.5mm (20mil) 0.6mm (24mil) 0.7mm (28 mil) 0.8mm (32 mil) 1.0mm (39 mil) 1.2mm (47 mil) 1.5mm (59mil) | 0.9mm (35mil) 1.1mm (43 mil) 1.3mm (51 mil) 1.4mm (55 mil) 1.6mm (63 mil) |

| Aluminum | 0.2mm (8mil) 0.25mm (10mil) 0.3mm (12mil) 0.35mm (14 mil) 0.4mm (16mil) 0.5mm (20mil) 1.5mm (59mil) | 0.15mm (6 mil) 0.45mm (18mil) |

| Stainless Steel | 0.15mm (6 mil) 0.2mm (8mil) | – |

What is FPC and Rigid-Flex PCBs Stackup?

1.FPC Stackup

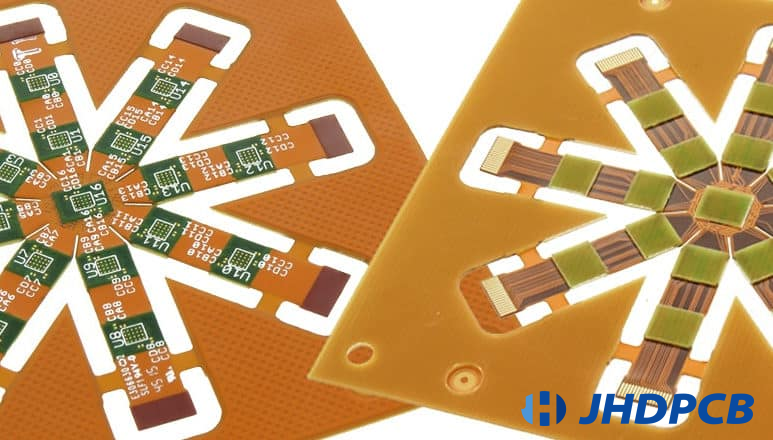

Flexible printed circuit boards, commonly referred to as flex circuit boards, flex PCBs, flex circuits, or flexible printed circuits, are specialized circuit boards that utilize a flexible substrate to accommodate various shapes and configurations. Unlike traditional rigid printed circuit boards, flex PCBs have the unique ability to bend and conform to specific requirements, making them ideal for applications where flexibility is crucial. Despite their flexible nature, these boards maintain the same components and functionality as their rigid counterparts.

Flex circuit boards can be classified based on their configurations and layers.

Classification Based on Configurations

- Rigid-Flex PCBs: These hybrid PCBs combine the advantages of both flex and rigid PCBs. They consist of a series of rigid circuits held together by flex circuits. Rigid areas are used for mounting connectors and components, while flexible areas provide vibration resistance. This configuration allows PCB designers to create innovative circuit boards for challenging applications. We will talk about this in detail later in this section.

- HDI Flexible PCBs:HDI, which stands for high-density interconnect, represents a type of PCB (printed circuit board) that is particularly well-suited for applications demanding superior performance compared to standard flexible PCBs. HDI PCBs excel in their ability to accommodate high-density circuitry by incorporating advanced features like micro-vias, which enable the connection of multiple layers within a compact design. HDI flexible PCBs use thinner substrates, reducing package size and enhancing electrical performance.

Classification Based on Layers

- Single Sided Flexible Circuit Boards: Single-sided flexible circuit boards are a fundamental type of flexible PCB that consists of a single layer of flexible polyimide film with a thin copper layer. The conductive copper is accessible from one side of the circuit, providing a simple and straightforward design for various applications.

- Single Sided Flexible Circuit Boards with Dual Access:Single-sided flexible circuit boards with dual access have a design similar to traditional single-sided boards, but with the added advantage of the copper conductor being accessible from both sides. This feature allows for increased flexibility and convenience in terms of component placement and connection.

- Double Sided Flexible Circuit Boards: These boards have two layers of copper or conductors on each side of the polyimide pi base layer. Metalized plated through holes enable electrical connections between the conductive layers.

- Multi-Layered Flexible Circuits:These circuits combine multiple double-sided and single-sided flexible circuits. Plated-through holes or surface-mounted components interconnect the circuits in a cohesive pattern.

Stack-up for FPC

Below is the standard stack-up information for FPC. If you require a customized FPC stack-up from Use, please indicate your specifications, and at JHDPCB we will manufacture it accordingly.

“Request Flex PCB Manufacturing Quote From JHDPCB Now”

| Single Layer FPC Stackup | ||

| Top Coverlay | PI | 12.5um |

| Adhesive | 15um | |

| Top Copper Layer | ||

| Copper | 18um(Finished Copper thickness 18um | |

| Adhesive | 13um | |

| PI | 25um dielectric constant 3.3~3.5 | |

| Total Thickness | ||

| 83.5um | ||

| 2 Layer FPC Stackup | ||

| Top Coverlay | PI | 12.5um |

| Adhesive | 15um | |

| Top Copper Layer | ||

| Copper | 18um(Finished Copper thickness 18um | |

| Adhesive | 13um | |

| PI | 25um dielectric constant 3.3~3.5 | |

| Total Thickness | ||

| 83.5um | ||

| Standard 4 Layer PCB Stackup | ||

| Top Coverlay | PI | 12.5um |

| Adhesive | 15um | |

| Top Copper Layer | ||

| Copper | 12um(Finished Copper thickness 18um | |

| Adhesive | 0um | |

| PI | 25um dielectric constant 3.3~3.5 | |

| Per gum | 13um | |

| Copper 2 Layer | ||

| Copper | 12um | |

| Adhesive | 0um | |

| PI | 25um | |

| Adhesive | 0um | |

| Copper 3 Layer | ||

| Copper | 12um | |

| Pure gum | 13um | |

| PI | 25um dielectric constant 3.3~3.5 | |

| Adhesive | Oum | |

| Bottom Copper Layer | ||

| Copper | 12um | |

| Bottom Coverlay | ||

| Adhesive | 15um | |

| PI | 12.5um | |

| Total Thickness | ||

| 204um | ||

| 6 Layer FPC Stackup | ||||

| Top Coverlay | PI | 12.5um | ||

| Adhesive | 15um | |||

| Top Copper Layer | ||||

| Copper | 12um(Finished Copper thickness 18um | PI | 12.5um | |

| Adhesive | 0um | Adhesive | 15um | |

| PI | 25um dielectric constant 3.3~3.5 | Copper | 18um | |

| Per gum | 13um | Adhesive | 13um | |

| Copper 2 Layer | ||||

| Copper | 12um | PI | 25um dielectric constant 3.3~3.5 | |

| Adhesive | 0um | Adhesive | 13um | |

| PI | 25um | Copper | 18um | |

| Adhesive | 0um | Adhesive | 15um | |

| Copper 3 Layer | ||||

| Copper | 12um | PI | 12.5um | |

| Pure gum | 13um | |||

| PI | 25um dielectric constant 3.3~3.5 | |||

| Adhesive | Oum | |||

| Copper 4 Layer | ||||

| Copper | 12um | FPC thickness | 142um | |

| Adhesive | 0um | |||

| PI | 25um | |||

| Adhesive | 0um | |||

| Copper 5 Layer | ||||

| Copper | 12um | |||

| Pure gum | 13um | |||

| PI | 25um dielectric | |||

| Adhesive | Oum | |||

| Bottom Copper Layer | ||||

| Copper | 12um | |||

| Bottom Coverlay | Adhesive | 15um | ||

| PI | 12.5um | |||

| Total Thickness | ||||

| 293.5um | ||||

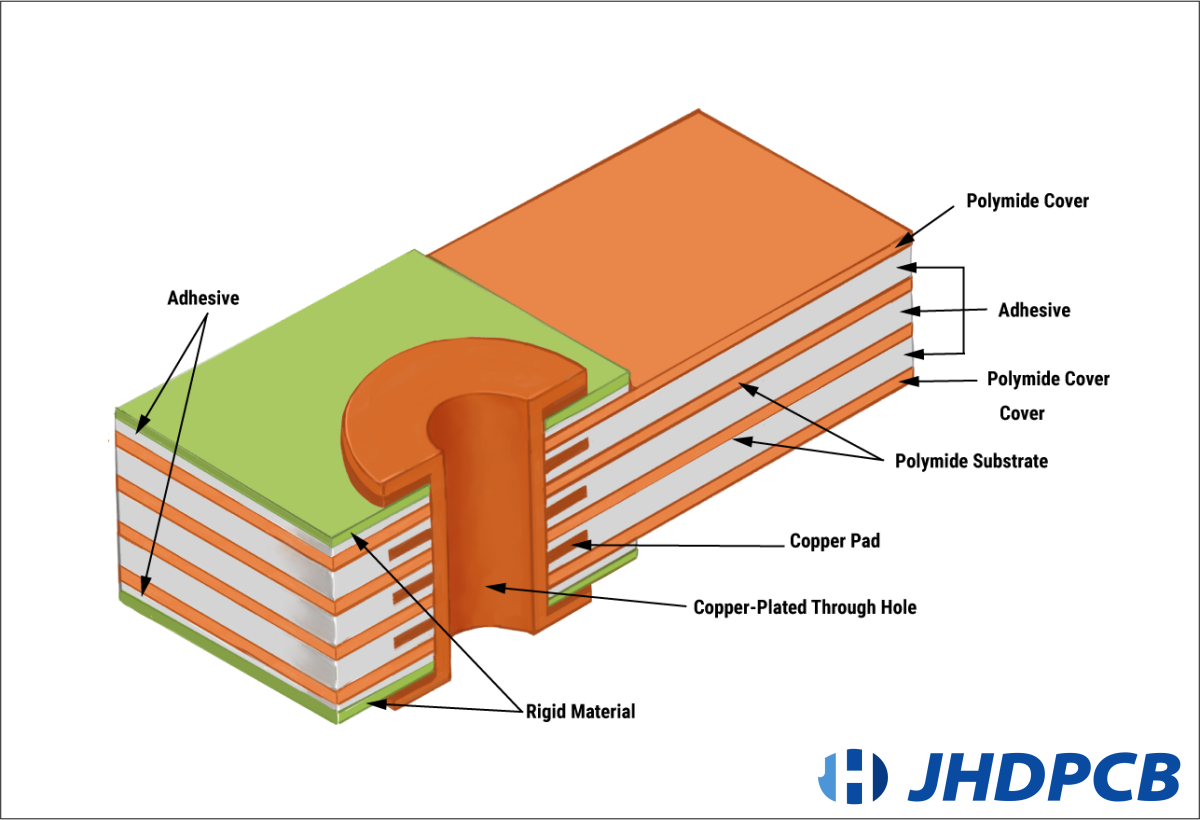

2.Rigid-Flex PCBs Stackup

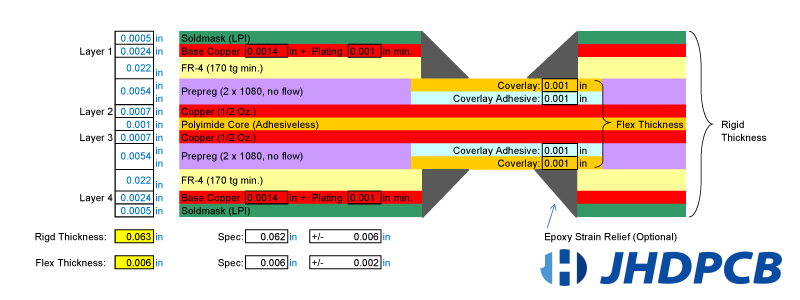

A rigid flex PCB stackup basics refers to a type of printed circuit board assembly that combines both rigid and flexible substrate materials. It consists of three or more laminated layers, with rigid and flexible portions bonded together.

The rigid substrate provides structural strength, while flexible circuits are used in areas that require bending or folding. This hybrid design allows components to be placed on rigid areas for surface mounting, while conductive traces can flexibly route around corners or conform to uneven spaces.

Rigid flex boards integrate connections, lowering the number of discrete solder joints and connectors needed compared to standard PCB designs. This helps minimize potential defects. By leveraging thin flexible films, rigid flex construction can achieve more compact thickness profiles without compromising reliability. Stackups may be as small as 0.2-0.4mm.

Rigid flex technology expands design possibilities by blending rigid and flexible circuits. This combines the benefits of each into a single board assembly. Fewer connectors and compact dimensions also enhance manufacturability. Overall, rigid flex stackups provide engineers flexible, space-efficient solutions for advanced electronics.

| 4 Layer Rigid Flex – FPC Stackup | ||||

| Rigid Part | Flex Part | |||

| Top Solder Mask Layer | 20um | |||

| Rigid Top Copper Layer | ||||

| Copper | 18um(Finished Copper thickness 35um) | |||

| FR4 | 680um | PI | 12.5um | |

| Pure gum | 13um | Adhesiver | 15um | |

| Flex-Copper 2 Layer | ||||

| Copper | 18um | Copper | 18um | |

| Adhesive | 13um | Adhesive | 13um | |

| PI | 25um dielectric constant 3.3~3.5 | PI | 25um dielectric constant 3.3~3.5 | |

| Adhesive | 13um | Adhesive | 13um | |

| Flex-Copper 3 Layer | ||||

| Copper | 18um | Copper | 18um | |

| Pure gum | 13um | Adhesive | 15um | |

| PI | 25um | Copper | 18um | |

| FR4 | 680um | PI | 12.5um | |

| Rigid-Bottom Copper Layer | ||||

| Copper | 18um | |||

| Bottom Solder Mask Layer | 20um | |||

| Pure gum | 13um | |||

| Total thickness | 1549um | FPC thickness | 142um | |

What's Features Of Rigid Flex PCBs Stackup?

Rigid flex PCB stackup designs offer several advanced features that set it apart from conventional printed circuit boards. These features not only improve the overall performance and reliability of the boards but also contribute to reducing the risk of errors and failures. Let’s delve into these features in more detail:

Reduced Solder Joints and Connectors:

Compared to traditional PCBs, rigid flex stackup incorporates fewer solder joints and connectors. This reduction minimizes the chances of soldering errors, which can be costly to rectify and may even result in circuit failure. By streamlining the soldering process, rigid flex PCBs enhance the overall reliability of the circuit.

Optimal Board Thickness:

Rigid flex technology employs thin films to achieve an effective reduction in board thickness without compromising quality or reliability. These boards typically range from 0.2mm to 0.4mm in thickness, making them more durable while maintaining their functionality.

Improved Thermal Strength:

Rigid flex PCBs excel in heat dissipation, offering superior thermal strength compared to standard rigid boards. This enhanced thermal management capability ensures that the PCB can withstand high temperatures without compromising its performance or longevity. With a rigid flex PCB, concerns about overheating and potential damage are significantly reduced.

High Aspect Ratio:

Rigid flex PCBs boast a high aspect ratio, where the width exceeds the height. This characteristic allows for increased spacing between components on the circuit board, facilitating better high speed signals transmission. Moreover, the high aspect ratio simplifies the routing of wires and other components, making the overall design and assembly process more efficient.

Effective Solder Masking:

Solder masking is a crucial protective layer applied to the PCB, defining the component positions. It safeguards the components from abrasion and shields them against electrostatic discharge. By coating the board with an ink-receptive material that adheres to the PCB, solder masking ensures the longevity and reliability of the components.

Overall, we can say that rigid flex pcb layer stackup offers a range of advanced features that enhance the overall performance, reliability, and durability of the circuit. With reduced solder joints and connectors, optimal board thickness, improved thermal strength, high aspect ratio, and effective solder masking, these boards provide a robust solution for various applications.

Why Use Rigid Flex PCB?

There are several compelling reasons to use rigid-flex PCBs. In addition to offering the standard 3D freedom of flexible circuit boards, they provide various benefits such as reduced maintenance and a more consistent electrical profile.

Rigid-flex PCBs also contribute to optimized housing solutions by minimizing stress in critical flex areas and improving thermal uniformity through copper ratio adjustments. These advantages make rigid-flex PCBs a preferred choice in many applications. Here are some key reasons why rigid-flex PCBs are utilized:

- 3D Freedom and Flexibility:Rigid-flex design allows for the creation of three-dimensional shapes and configurations, enabling more flexible circuit board layouts. This flexibility facilitates the accommodation of tight spaces and the ability to conform to the product’s shape, making it highly suitable for compact and complex designs.

- Decreased Maintenance: Rigid flex PCBs reduce the need for connectors and cables, which can be prone to wear and tear. With fewer interconnections, there is less chance of failure or maintenance issues, resulting in improved reliability and reduced maintenance costs.

- Uniform Electrical Profile:Rigid flex PCBs offer a more uniform electrical profile compared to traditional PCBs. The combination of rigid and flexible layers helps to optimize signal integrity and minimize impedance variations, leading to improved performance and reduced signal loss.

- Improved Housing Solutions: Rigid flex PCBs enable optimized housing solutions by allowing the PCB to be integrated directly into the product’s structure. This integration can lead to space savings, improved structural integrity, and enhanced overall product design.

- Durability and Flexibility:Rigid flex PCBs are designed to withstand mechanical stress and offer excellent durability. The combination of rigid and flexible materials provides the necessary flexibility without compromising the board’s structural integrity, making it suitable for applications that require repeated bending or flexing.

- Space Saving: Another best thing is rigid flex PCBs are known for their space-saving capabilities. The thin and wide surface area of these PCBs allows for complex circuitry to be implemented without sacrificing efficiency. This space-saving feature helps reduce production costs and enables the integration of multiple components into a single layout.

- Single Point Connection: Rigid flex PCBs offer a robust and reliable connection between the electronics and supporting structure. This single point connection simplifies fabrication and troubleshooting processes, reduces electromagnetic compatibility (EMC) issues caused by cable interactions, and minimizes the chances of errors during production.

- Lightweight: Rigid flex PCBs are lightweight due to the use of low-density flexible substrates. Their unique design allows for the integration of rigid and flexible sections, enabling significant weight savings compared to traditional rigid PCBs. The combination of lightweight flexible materials and optimized layout contributes to a reduction in overall board weight without compromising the strength and reliability of the PCB. This makes rigid-flex PCBs an ideal choice for industries such as aerospace, automotive, and portable electronic devices, where weight reduction plays a vital role in achieving desired outcomes.

- Suitable for Vibratory and Shocking Environments:Rigid flex PCBs have superior mechanical strength and thermal characteristics, making them ideal for environments with vibrations, shocks, or sudden impacts. They help distribute stress more effectively, protecting the devices and ensuring higher reliability.

- Improved reliability: Another benefit is their reliability. Rigid-flex PCBs offer enhanced reliability in comparison with traditional rigid PCBs. The flexible portions of the board can withstand bending, twisting, and vibration, reducing the risk of mechanical failure. Additionally, the absence of connectors and cables minimizes the potential for loose connections or intermittent contact.

- Ease of assembly:Rigid-flex PCBs simplify the assembly process by reducing the number of interconnections and solder joints. This leads to faster and more efficient manufacturing, reducing the risk of assembly errors and improving overall production yields.

Overall, rigid flex PCBs offer a combination of flexibility, durability, space-saving capabilities, and reliability, making them a preferred choice in various industries and applications.

What Types of Material Used for Rigid-Flex Construction/Stackup/Structure?

Rigid-flex construction involves the combination of rigid and flexible materials to create a unique pcb stacking and structure. There are different types of materials are used in this process, including copper foil, FR4, prepreg, and adhesive.

Copper Foil

Copper foil is commonly used in rigid-flex construction as it provides excellent electrical conductivity and is highly flexible. It is typically used as a conductor for signal and power transmission within the flexible portions of the designing rules.

FR4

FR4, also known as Flame Retardant 4, is a popular choice for printed circuit board (PCB) fabrication. It is a fiberglass-reinforced epoxy laminate that offers outstanding electrical insulation properties and mechanical strength. In rigid-flex construction, FR4 is commonly employed as the rigid component of the stackup, providing structural support and stability to the PCB assembly. Its reliable performance makes FR4 an ideal material for ensuring the integrity and durability of rigid-flex PCBs.

Prepreg

Prepreg is a composite material that consists of reinforcing fibers embedded in a resin matrix. The term “prepreg” stands for pre-impregnated resin, indicating that the resin is already partially cured or impregnated into the fibers before use. This combination of resin and fibers provides strength, rigidity, and other desired properties to the material. It is used in rigid-flex construction as an insulating number of layers between the copper and insulators foils and the rigid FR4 layers. Prepreg helps to bond the layers together and provides electrical insulation.

Adhesive

Adhesive plays a vital role in rigid-flex construction as it is utilized to bond the various layers of the stackup together. This bonding process is essential for ensuring the structural integrity of the rigid-flex PCB and preventing delamination, where layers separate from each other. Adhesive materials are carefully selected to provide strong adhesion while maintaining flexibility in the flexible portions of the design.

In addition to these materials, other components such as solder mask, coverlay, and stiffeners may also be used in rigid-flex construction to enhance the overall performance and reliability of the flexible PCB.

Please note that the information provided is a general overview of the materials used in rigid-flex construction. The specific materials and their configurations may vary depending on your design requirements.

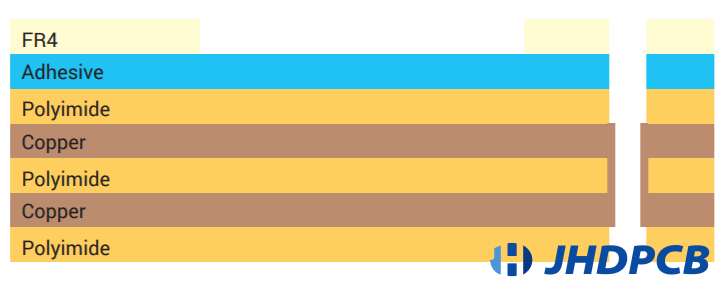

Common Flex Circuit Material Stack-Up

Here are some examples of typical material stack-ups used in the construction of rigid-flex and flex circuit boards. However, if you require further details regarding flex circuit construction methods, please feel free to reach out to one of our experts at JHDPCB By Clicking here.

1 Layer Flex PCB with Optional FR-4 Stiffeners and PSA

2 Layer Flex Circuit with ZIF Contact Fingers

4 Layer Rigid-Flex PCB (2 Flex Layers)

What FPC Thicknesses?

The thickness of Flexible Printed Circuit (FPC) varies based on specific applications and requirements. Generally, FPC thickness ranges from 0.1mm to 1.0mm. Below are the common FPC thickness ranges and their typical applications:

- Ultra-thin FPC:This type of FPC has a thickness of less than 0.1mm and is commonly utilized in thin and lightweight electronic products. It is chosen to meet space and weight constraints while maintaining flexibility.

- Thin FPC:Ranging from 0.14mm to 0.2mm, thin FPC is suitable for relatively slim electronic devices. It provides the necessary flexibility while accommodating the compact form factor of these devices.

- Thick FPC:Having a thickness between 0.5mm and 1.0mm, it is suitable for applications that require higher strength and stability

When selecting an FPC, it is important to consider not only the requirements of the FPC itself but also factors such as circuit components, connectors, and housings. Therefore, the most suitable thickness range should be determined based on actual needs, product design, and performance requirements.

From the flexible PCB manufacturer JHDPCB, FPC boards have a thickness range from 0.08mm to 1.0mm. The smaller the thickness of the FPC boards, the better the flexibility. The FPC thickness is determined by the combined thickness of the PI (polyimide), adhesive, and copper layers.

If the FPC has ink layers, their thickness should also be taken into account. According to JHDPCB, the RA (rolled annealed) or ED (electrodeposited) copper thickness of FPC boards can range from 1/3 oz to 3oz. It’s important to note that 1 oz is equivalent to 35μm.

The FPC copper thickness options available are 12μm, 18μm, 35μm, 70μm, and 105μm.The PI thickness options are 12.5μm, 25μm, 50μm, or 75μm. Additionally, the adhesive thickness provided by JHD stackup is 20μm. Apart from the FPC thickness, it is also important to consider the finished FPC width when discussing requirements with the FPC manufacturer.

The stackup of flexible printed circuit boards (FPCs) and rigid-flex PCBs plays a crucial role in their performance and reliability. The proper selection and application of stiffeners are essential for ensuring the mechanical stability and functionality of these PCBs. At JHDPCB, as a leading provider in the industry, we understand the importance of FPC stackup analysis and offer comprehensive solutions tailored to meet specific project requirements of our clients.

JHDPCB’s expertise in FPC stackup enables us to deliver high-quality flexible PCBs and rigid-flex PCBs with optimal performance. Our commitment to using superior materials, such as copper foil, FR4, prepreg, and adhesive, ensures the durability and reliability of our products. Moreover, JHDPCB understands the importance of maintaining consistent thickness and proper overlap to alleviate stress and enhance solder joint strength.

Whether you require 1-6 layer board stackup or rigid-flex PCBs with stiffeners, JHDPCB has the knowledge and experience to provide tailored solutions that meet your specific needs. Our commitment to delivering exceptional quality, meticulous attention to detail, and unwavering dedication to customer satisfaction distinguishes us in the industry.

Choose JHDPCB for your flexible PCB and rigid-flex PCB needs, and experience the reliability and performance that our stackup solutions offer.