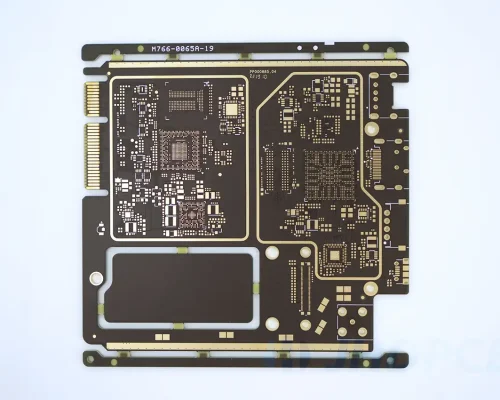

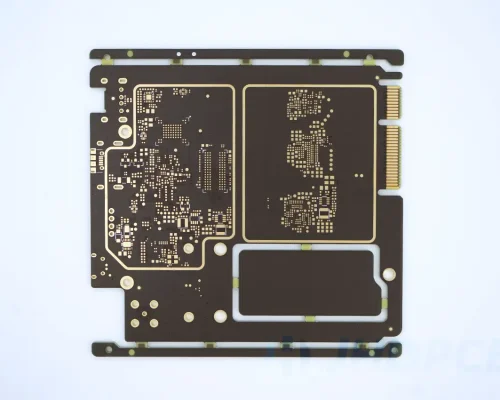

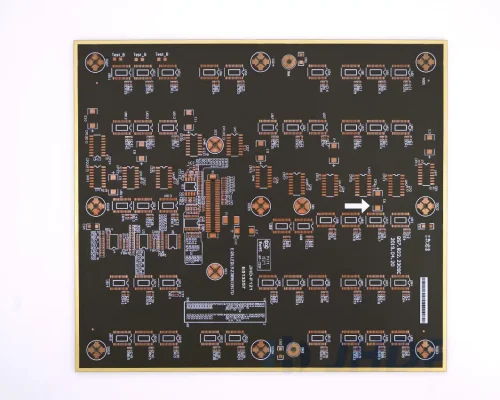

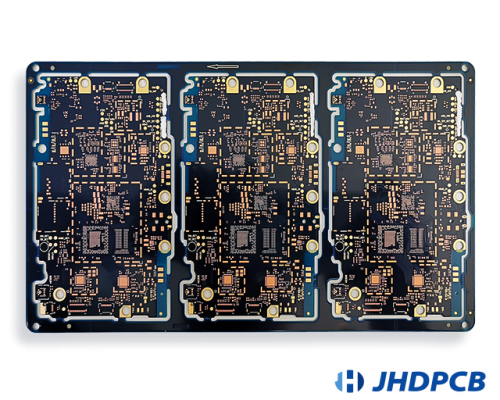

Automotive Transportation Industry PCB

Automotive Transportation PCB Application and Prospect.

With the continuous development of the automotive and transportation industry, more and more electronic devices and systems are used in vehicles and transportation facilities. These devices and systems require reliable circuit boards to support their normal operation. From traditional mechanical control systems to modern electronic control systems, PCBs play a vital role in the automotive and transportation industries. Below we will briefly introduce the application of PCB in the automotive and transportation industry, market size and prospects, as well as related new technologies, new products and new market opportunities.

Application of PCB in the automotive industry:

With the technological innovation and intelligent development of the automobile manufacturing industry, the application of PCB in the automobile industry is becoming more and more extensive. Including sensors, controllers, entertainment and communication systems, etc. The following are more specific applications:

- Sensors: Various sensors used in automobiles require PCBs to support their work, such as temperature sensors, oil pressure sensors, oxygen sensors, and more.

- Controller: Various controllers of the car need PCB to connect various sensors and actuators, such as engine control module (ECM), brake control module (BCM), body control module (BCM) and so on. The running status of the car is obtained through sensors, and then the data is transmitted to the ECM through the circuit board on the PCB in order to adjust the running status of the vehicle.

- Entertainment and communication systems: dashboards, entertainment and communication systems in cars require PCBs for audio, video and data transmission and processing, such as audio amplifiers, radios, GPS navigation systems, and more. The wide variety of entertainment devices equipped in modern vehicles require high-quality circuit board support.

- Safety system: Automotive safety systems include braking systems, airbags and seat belts, etc. These systems require reliable circuit boards to support their normal operation.

Power system: Automotive power systems include batteries, generators and motors, etc. These systems require high-quality circuit boards to support their normal operation. - New energy vehicle charging technology: With the development of smart cars and smart transportation, the application prospects of PCBs in these industries are very broad. Charging technology has also become the focus of attention. At present, the charging technology of new energy vehicles is mainly divided into three types: DC fast charging, AC fast charging and AC slow charging.

DC fast charging technology is a fast charging technology with a fast charging speed, which can charge 80% of the battery in a short period of time. AC fast charging technology is a technology for fast charging under the AC grid. AC slow charging technology refers to the technology of using AC power for charging in households, public places and other occasions.

According to a market research report, the global new energy vehicle charging market is expected to grow from US$15.7 billion in 2020 to US$40.6 billion in 2025, and the global automotive electronics market is expected to reach US$330 billion in 2025. This shows the potential and growth trend of the new energy vehicle charging market, and also shows that the application and market prospects of PCB in this field are very broad.

Application of PCB in the transportation industry.

In addition to the automotive industry, PCBs are also widely used in the transportation industry, including aircraft, trains and ships. The following are some specific application situations:

- Train: Various controllers and instruments in the train need PCB to realize data transmission and processing, such as train control system, braking system, signal system and so on. At the same time, the railway signal control system needs reliable circuit boards to support its normal operation, so as to ensure the safety and smoothness of railway traffic.

- Ships: Various controllers and instruments in modern ships need PCBs to realize data transmission and processing, such as steering gear control systems, engine control systems, navigation systems, etc.

- Aircraft: Various controllers, dashboards, and communication systems in aircraft require PCBs for data transmission and processing, such as flight control systems, engine control systems, navigation systems, and so on.

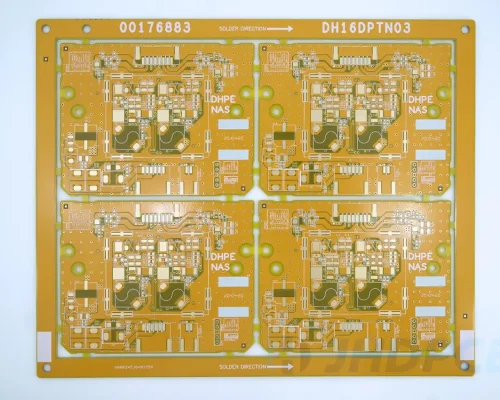

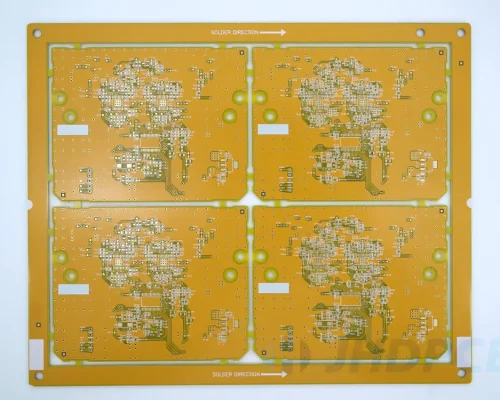

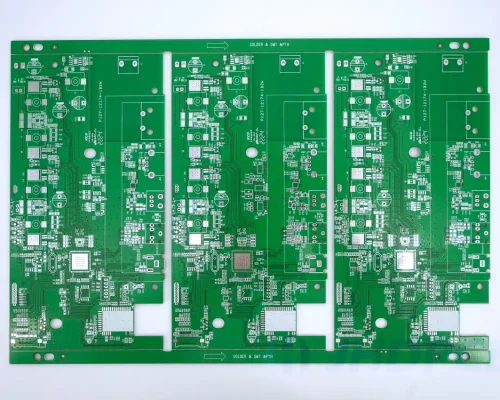

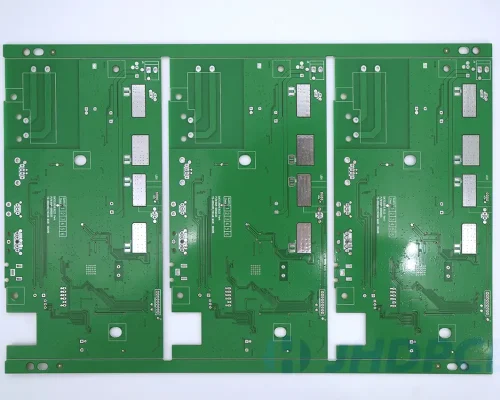

As a PCB manufacturer, we can provide a variety of high-quality PCB manufacturing services to provide reliable electronic equipment for the automotive and transportation industries.

Automotive PCB Application Scenarios

- Electronic Control Unit (ECU)

- Electric vehicle battery management system (BMS)

- Electric vehicle charging pile control unit

- Electric vehicle motor controller

- Autopilot System

- Body control unit (BCU)

- Steering gear controller

- Brake system controller

- Engine management system

- Power door and power window controls

- Two-way wireless remote

- Audio and video entertainment systems

- GPS system

- Reversing radar and camera control unit

- Airbag Controller

- Vehicle monitoring system

- Headlight and Taillight Controllers

- Light control unit for brake light, direction light, etc.

- Air Conditioning System Controller

- Fan and Pump Controllers

- Seat Heating and Ventilation Controllers

- Audio and multimedia control unit

- Vehicle WiFi and Bluetooth system

- Dashboard system

- Seat Belt Sensor

- Car charger

- Air purification system controller

- Oil quantity sensor and water temperature sensor

- Tire Pressure Monitoring System

Why choose JHD Car Traffic PCB

We will have engineers conduct DFM and DFA analysis before scheduling production to prevent design problems, and implement an internal quality review system to guarantee zero-defect boards. Make sure your design performs as expected and meets IPC Class 2&3 standards.

- Identify potential failures;

- Suggest Design Improvements;

- Follow DFM rules and guidelines;

- Verify the result of the change.

If a circuit board is circulated between different manufacturing shops and assembly shops, it is easy to cause miscommunication leading to delivery delays and circuit board errors. Remember that a PCB manufacturer that does not handle assembly will not run DFA inspections. And JHD can do it all to make sure your board can be assembled properly.

Automotive PCB standards mainly include the following aspects:

- AEC-Q100: It is a reliability test standard for automotive electronic components issued by the Society of Automotive Engineers (SAE), including temperature, humidity, voltage and other tests.

- SAE J-STD-001/Q101: Electronic assembly reliability standard, including reliability, manufacturing and assembly requirements of electrical and electronic assemblies, etc.

- SAE AS5553/Q102: Nonconforming and Fraud Exclusion Criteria for Electronic Components, designed to reduce the failure rate of electronic assemblies in manufacturing and repair.

- SAE J-STD-020/Q104: Soldering reliability standard, including the reliability, soldering process and test methods of surface mount and plug-in electronic components.

- SAE J-1739/Q200: Guidelines for Reliability of Electronic Assemblies, includes guidelines and best practices for evaluating and managing the reliability of electronic assemblies.

- IPC-6012: is an automotive printed circuit board quality standard issued by IPC (International Printed Circuit Council) to ensure the reliability of electronic interconnection circuit boards exposed to high vibration and high temperature.

- IPC 6011: It is an IPC standard that regulates the quality requirements of automotive electronic PCBs. It mainly includes regulations on materials, manufacturing processes, dimensional control, interlayer connections, metallization, and environmental tests. The standard also provides some PCB quality assessment methods and testing requirements.

- IATF 16949: It is the international automotive industry quality management system standard, which requires strict quality control in all links of the automotive supply chain, including PCB manufacturing.

- ISO 26262: It is an automotive electronic safety standard that requires automotive electronic systems to undergo rigorous safety analysis and evaluation, including PCBs.

- JASO D001: It is an automotive printed circuit board standard issued by the Japan Automobile Standards Association, including standards for design, manufacturing, and testing.

- UL 94: It is a flammability test standard that requires PCB materials to meet the UL 94 standard to prevent fires in vehicle accidents.

- PPAP: It is most commonly utilised within the automotive industry and is integrated into the Advanced Product Quality Planning (APQP).

- IMDS: Complete international material data system, implement strict material monitoring.

In addition to the above standards, different car manufacturers may also have their own standards and requirements, such as Volkswagen Group Requirements (VWGR) of German Volkswagen. Therefore, during the automotive PCB manufacturing process, JHD strictly abides by relevant standards and requirements to ensure the quality and reliability of the PCB, thereby ensuring the safety and stability of the entire automotive electronic system.

As an important part of the automotive electronic system, the automotive PCB needs to have high reliability and stability. In order to ensure the quality and reliability of PCB, JHD has a complete testing system for various verifications to ensure that it meets the relevant standards and regulations of the automotive industry. The following is the main content of the JHD automotive PCB testing system.

- Circuit continuity test:

Circuit continuity test is the most basic test, which is mainly used to detect whether the circuit on the PCB is connected correctly. This test uses a special test instrument to touch the tester head to the test point on the circuit board to ensure that the various parts of the circuit board are connected correctly. - Signal Integrity Test:

Signal integrity testing is mainly for testing the transmission quality of high-speed digital and analog signals to ensure the accuracy and stability of data transmission. This test usually involves the measurement of parameters such as impedance, transmission delay, and signal reflection of the signal transmission line to detect the integrity of the signal. - Electrical Performance Test:

Electrical performance testing is the process of testing the electrical performance of the PCB board, including the measurement of parameters such as input and output resistance, capacitance, inductance, etc., to ensure that the electrical performance of the circuit board meets the specification requirements. - Environmental Adaptability Test:

Environmental adaptability testing is the process of testing the stability of PCBs under different environmental conditions. The tests include high and low temperature environment, high humidity environment, thermal cycle test, oil resistance test, etc. to ensure that the PCB can maintain stability in different working environments. - Reliability Test:

The reliability test is a test to detect the stability and reliability of the PCB during long-term use. Tests include heat aging test, vibration test, thermal shock test, etc. to ensure that the PCB will not fail or be damaged during long-term use.

In short, the automotive PCB testing system is an important safeguard. In order to ensure that the PCB can meet the relevant standards and regulations of the automotive industry, JHD will conduct a comprehensive and strict test on all automotive PCBs to ensure the reliability and stability of the automotive electronic system. Such as cross section, AOI, BGA X-ray, flying probe and other electrical tests.

JHD LED PCB Products