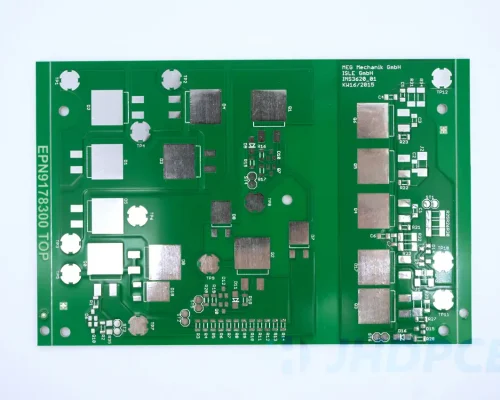

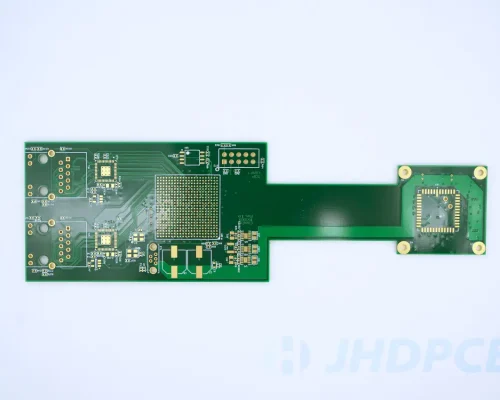

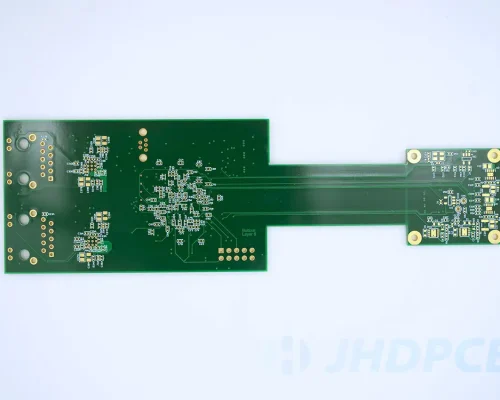

PCB for Consumer Electronics Industry

Market Size and Prospect of Consumer Electronics PCB.

PCBs are widely used in the consumer electronics industry, and almost all consumer electronics products need to use PCBs. Such as smartphones, TVs, tablets, laptops, game consoles, smart wearable devices, audio, smart homes, home appliances, etc. PCB provides key circuit support and interconnection for consumer electronic products. Its role is to provide circuit connection, power management, signal processing, power amplification and other functions to ensure the normal operation of electronic equipment.

The consumer electronics industry is a huge market. With the continuous improvement of people’s living standards and the continuous advancement of technology, the demand for consumer electronics products continues to grow, and the market prospect is broad. According to data from market research institutions, the scale of the consumer electronics market is constantly expanding and is expected to reach US$3.1 trillion by 2027, among which smart devices such as smartphones and tablet computers will be the main growth drivers.

Development trend of consumer electronics PCB.

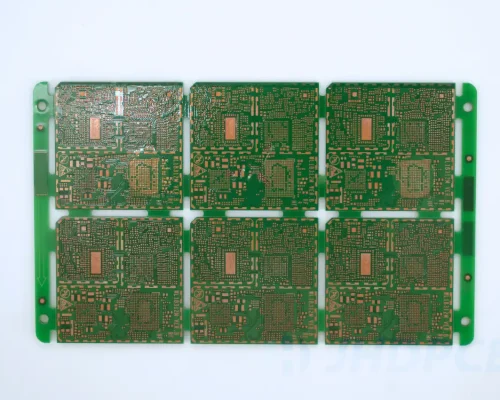

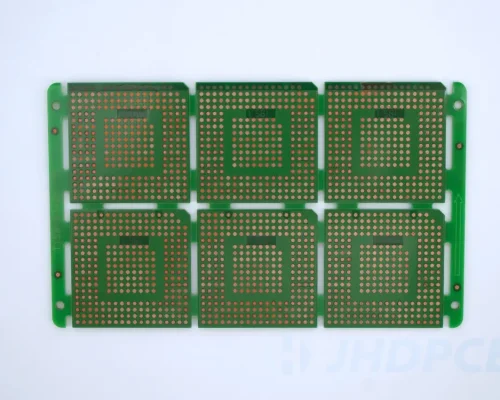

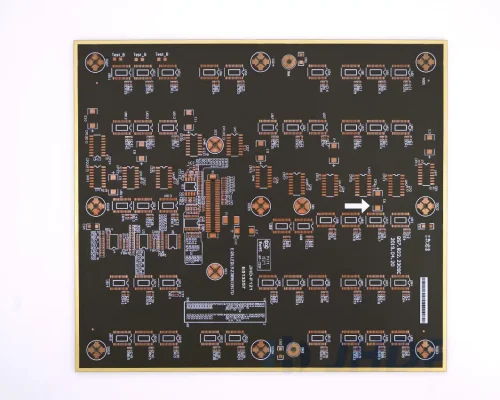

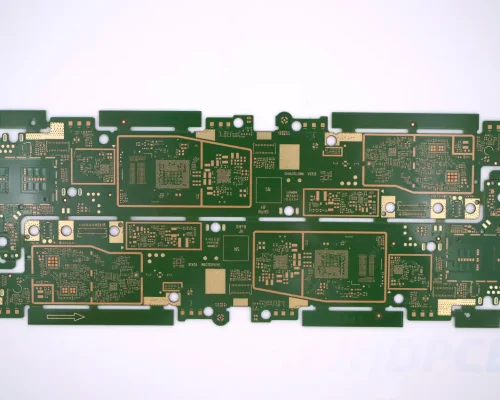

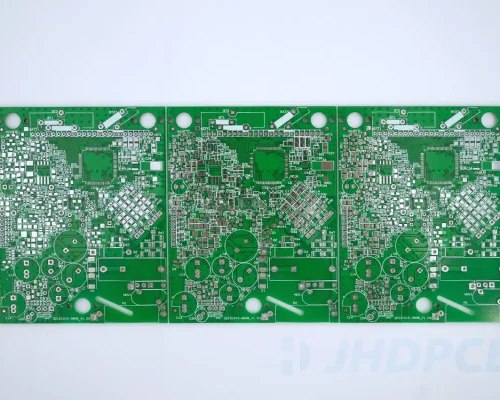

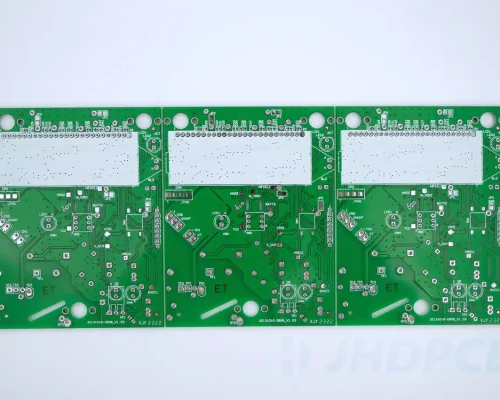

With the continuous upgrading of consumer electronics products, the functions and performance of consumer electronics products continue to improve, and the requirements for PCB are getting higher and higher. Such as smaller size, higher density and better signal transmission performance. High-density HDI PCB and multi-layer PCB came into being. In order to improve the stability and reliability of the product, strict quality control and testing are required during the PCB manufacturing process.

The prospect of the consumer electronics industry is very broad. In recent years, with the development of new technologies such as 5G, artificial intelligence, and the Internet of Things, consumer electronics products will become more intelligent and diversified. The entire consumer electronics industry has also ushered in new opportunities and challenges. For example, with the development of smart home, consumer electronics products require more sensors and controllers, which also put forward higher requirements for PCB manufacturing. Therefore, the application prospect of PCB in the consumer electronics industry is still very broad.

In short, the consumer electronics industry is a market full of opportunities and challenges. With the continuous emergence of new technologies, the demand for consumer electronics products will also continue to grow. JHD will continue to invest more resources and energy to provide customers with the best quality consumer electronics PCB manufacturing services.

Consumer Electronics PCB Application Scenarios

- Mobile phone

- Tablet PC

- Notebook computer

- TV set

- Smart Speaker

- Digital Camera

- Smart Watches, Bracelets

- Smart Glasses

- Smart Sunglasses

- Game console

- Sweeping robot

- Dishwasher

- Air purifier

- Smart toilet cover

- Treadmill

- Smart home device

- Electronic writing board

- Smart Microphone

- Smart door lock

- Smart Body Fat Scale

- Drone

- Car navigator

- Router

- Wireless charger

- Smart lighting

- E-reader

- Smart Gloves

- ID Card Reader

- Voice assistant device

Why Choose JHD Consumer Electronics PCB

- 2, 4, 6, 8 layer boards, even more layers;

- 4 mil trace/space;

- 1-20OZ copper thickness;

- FR-4/cem3/glass/ceramic/metal core;

- Tented vias/plugged vias;

- Customized solder mask and silk screen;

- BOM inspection;

- DFM and DFA checks by experienced engineers;

- Assembly on both sides;

Click to view more detailed JHDPCB manufacturing capabilities.

Before manufacturing:

- DFM and DFA checks;

- BOM check;

- Special stack help/NPI review;

- Component engineering assistance and procurement.

After manufacture:

- Functional check;

- Thermal Cycling Test (TCT);

- Thermal Shock Test (TST);

- Temperature and Humidity Bias Test (THB);

- AOI report or appearance inspection report;

- Flying probe or online test report;

- Automated X-ray

- Inspection (AXI).

- Certificate of Conformity;

- ISO 9001 certification;

- RoHS;

- UL certification;

- IPC Class 2&3 Specifications;

- Material specification;

- Photo requirements;

- The first inspection report;

- IPC J-STD-001E;

- Records of calibration tools used during manufacturing;

- AOI report or appearance inspection report;

- Flying probe or online test report;

- Ion cleanliness test report.

As a PCB manufacturer, we have been focusing on consumer electronics PCB manufacturing for 14+ years. We have rich experience and technical strength in the field of consumer electronics PCB manufacturing. Our factory has a full set of modern equipment and tools, which can produce PCBs of various complexities, providing customers with high-quality and high-performance consumer electronics circuit board solutions.

Our professional technical team can carry out customized design according to the needs and requirements of customers to ensure that each project can meet the requirements of customers.

We adhere to the customer-centric principle, focus on quality and service, and provide customers with a full range of PCB manufacturing solutions, including full-process services from design to production and testing. We continuously optimize the production process and improve production efficiency to ensure fast delivery of high-quality products. In addition to fast lead times, we also provide competitive prices to ensure that customers can get the best PCB manufacturing services. At the same time, our customer service team also provides technical support and consulting services for customers at any time to ensure that customer needs are met in a timely manner.

If you need high-quality PCB manufacturing services in the field of consumer electronics, please contact us, we will provide you with the best quality solutions.

JHD Consumer Electronics PCB