Via Covering

directory

Via Covering means that the via is covered by a solder mask or other chemical materials. Why do I sometimes need to cover vias during PCB manufacturing? Because if the through hole is exposed, solder paste may enter the through hole and cause poor solder joints or short circuits. The situation where the via is not covered is called a via opening.

The seven common types of PCB via coverage.

Production-related requirements of PCB manufacturing or several technologies require via protection, so the via fill can be very important to your PCB. In general, these types of via coverage are possible:

- Simple Coverage: Via Tent or Tent Vias

- Partial Fill: Via Plugging or Plugged Vias

- Fully Filled: Via Filling or Filled Vias

But sometimes designers don’t fully understand all the available via coverage types and which ones to specify. Rather than confuse designers and manufacturers by simply specifying that vias must be “plugged” or “filled,” we recommend specifying specific IPC-4761 via type. This helps to make it easier for designers and manufacturers to understand. IPC-4761 specifies only mechanically drilled via types, not laser-drilled micro vias. Learn more about the types of PCB through holes.

Here are seven different types of via coverages as summarized in reference to IPC-4761 “Design Guidelines for Protection of Printed Board Via Structures”:

| The well-known and reliable CCL(Copper Clad Laminate)manufacturer we are cooperating | |

|---|---|

| Type & Description | Via Covering Material |

I-a Tented Via (one-sided) I-b Tented Via (double-sided)  | Dry film solder mask |

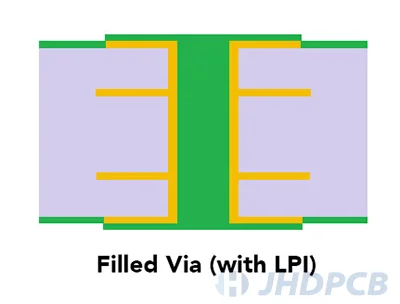

| II-a Tented & Covered Vias (one-sided)  II-b Tented & Covered Vias (double-sided)  | Dry film solder mask + LPI solder mask |

III-a Plugged Via (one-sided) III-b Plugged Via (double-sided)  | Plugging Epoxy (non-conductive paste) |

| IV-a Plugged & Covered Via (one-sided)  IV-b Plugged & Covered Via (double-sided)  | Plugging Epoxy + LPI solder mask |

V Filled Via | Plugging Epoxy (non-conductive paste) |

| VI-a Filled & Covered Via (one-sided)  VI-b Filled & Covered Via (double-sided)  | Plugging Epoxy + LPI solder mask |

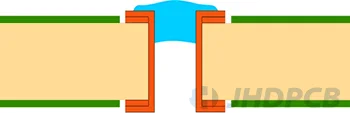

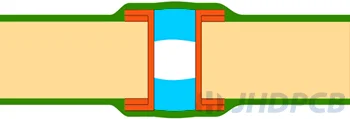

VII Filled & Capped Via | Special Plugging Epoxy + Copper Plating to planarization |

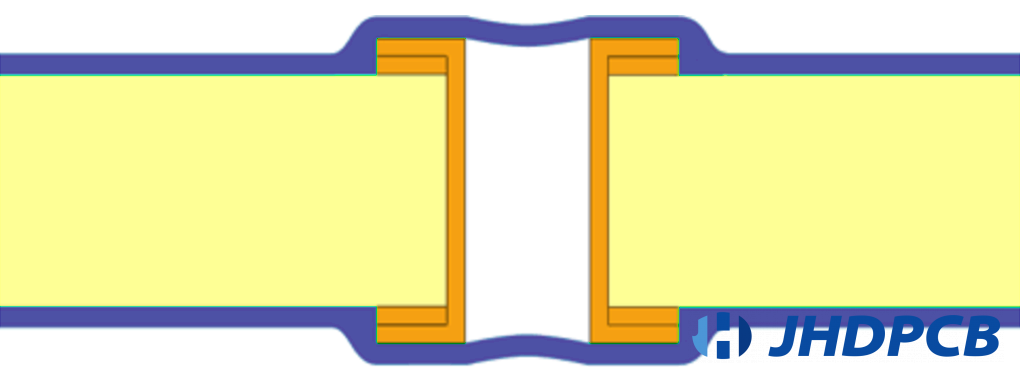

What is a tented vias?

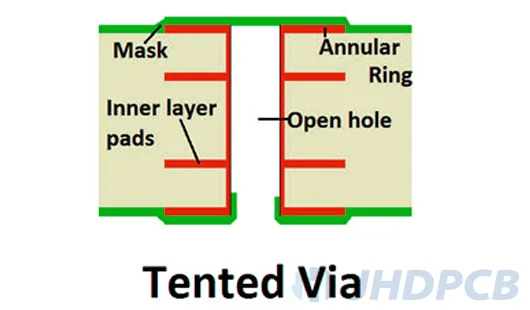

Via tented refers to covering the vias and annular rings with solder mask, that is, creating a shape like tent over the opening to hide the vias. A via is a hole comes from a PCB that allows signals connect from one layer to another on the PCB. Vias are generally copper-plated, so this material is strongly conductive. The main purpose of tenting vias is to reduce the number of exposed conductive pads on the PCB and decrease unexpected short circuit or touch circuits. So far, tented via is the most developed and prevalent process in PCB manufacture. Via tenting means that the through hole is only covered by solder mask ink . This is the easiest way of Via Covering. No additional process steps are required in the manufacturing process. Generally, vias using this type of coverage should not be larger than 0.3mm.

What is the role of vias tenting?

The main role of the tenting vias is to reduce the exposed conductive pads on the surface of the PCB. Exposed conductive pads can cause the migration of solder during handling, which mostly occurs when vias are located at the edge of the SMT pad. A via tenting not only reduce the solder paste migration on SMT pads, but also help cut off oxygen and moisture from the environment and avoid vias from being damaged by exposure to the nature.

When building PCB tented vias, the diameter of the vias is required to be small. The diameter of the via hole is less than 12mil, and the tent will be more effective. For vias over than 12mil in diameter, it is recommended to consider using some kind of filler to seal the holes. Because the copper-plating on the vias is very conductive, you don’t have to worry about the conductivity of the material when filling the vias.

The characteristics of tented vias.

Advantages:

- Tented vias can prevent damage to the PCB layer. the Solder mask to cover vias can protect copper traces from corrosion and oxidation

- Tented vias can reduce the number of conductive elements exposed to external element. In case of the inside of the via is prolonged exposure to the outside environment, it will cause corrosion of copper.

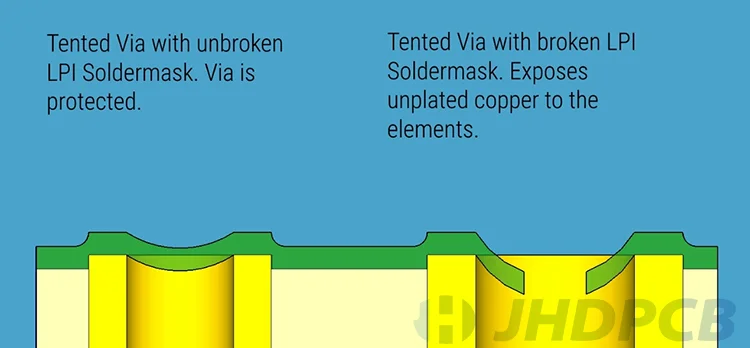

- Tented vias is an economical and effective protection method. Masking vias with liquid photoimaging solder mask is the most cost-effective way of masking.

Disadvantages:

- An obvious disadvantage of vias tenting is that because the solder mask used is a liquid, the liquid may crack after drying, and making small holes in the tent. The small holes that create can absorb chemicals and moisture, which can cause corrosion. In this way, the copper plating inside the barrel will also be gradually eroded, it will increase the possibility of via failure.

The solution to this problem is to expose the vias when the PCB is in the prototype stage of the manufacturing process. This helps to identify problems and fix them in a timely manner.

What are the precautions for using tenting vias?

When building vias tent, there are some points we need to pay attention to. The followings are explanations about close to SMT, assembly, and selection of double-sided.

Close to SMD:

If the via is placed too close to the SMD, it may cause the solder wick to stick to the back of the board. Here are three methods with the potential to prevent solder wicking:

- Selectively cover any vias near the SMD pad without altering the paste mask.

- Reduced solder paste mask opening so that less solder paste is deposited on problematic SMD pads.

- Keep these vias away from the SMD pads and make sure there is some solder mask between any pads and their connecting vias.

Assembly issues:

Sometimes tented vias can create some assembly issues. The following two issues you should consider when assembling tented vias for your PCB.

- Cover the vias near the component package if there is a chance of solder being drawn to the back of the board during assembly.

- Eliminate vias near or below the component package if excess flux residue will cause contamination and possible shorting issues. Learn more about PCB package process information.

Two sides:

Should the tent punch holes be on one side or both sides? Doing it on both sides of the PCB is the most ideal way. If only one side is tented, the un-tented vias on the other side will be exposed to the outside, leading to corrosion and oxidation. Especially in the double-sided PCB manufacturing process, it needs to be paid attention to.

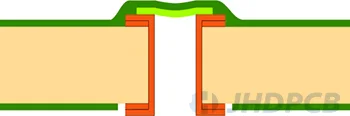

What is via plugging?

Plugged vias refer to a PCB technology that completely fills the hole with epoxy resin or closes the hole with a solder mask. There may also be no solder mask. We can think of the plugged via as a protective measure, which prevents excess solder material from flowing during soldering or assembly. Conversely, if a via is not plugged during soldering, solder will flow from the pad down the vias and may create unnecessary solder joints. The diameter of the plug hole is required to be less than 0.5mm, and the via hole can also be filled on both sides or on one side.

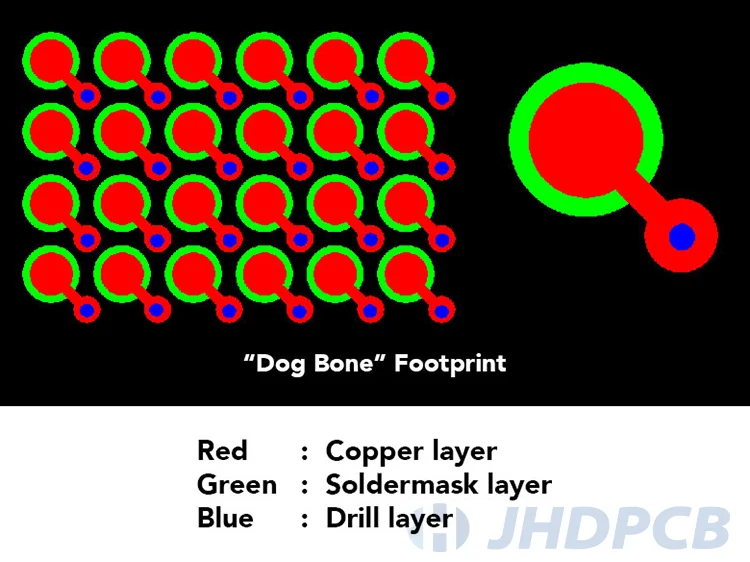

Today, BGA packages with smaller pitches or clearances are becoming more and more popular. Signals transmit from the BGA pads to the vias, and from the vias to other layers, instead of using standard “dog-bone” footprint, the vias can be drilled immediately into the BGA pads.

In this way, the track routing become easier and tighter when designing a PCB, as the via surface itself becomes a BGA pad, which can be soldered as if it were a normal SMD pad. This process is called “Via In Pad” and the pad is called “Active Pad”. More PCB pad knowledge can be learned through our blog.

What are the advantages and disadvantages of the two different types of via plugging?

There are two via plugging types, this ups to the plugging material that you choose to use. In some specific cases, conductive via plugs are a convenient solution. However, the most common and widely chosen is Non-Conductive Via Plugging. The following are the pros and cons of both types of via plugging.

Conductive Via Plugging:

Conductive via plugs are a convenient solution where some PCB designs require the transfer of electrical current or significant amounts of heat from one side of the board to the other. Among other things, it can be used to dissipate excess heat generated underneath certain components.

- Pros:

1. Due to the higher thermal conductivity of the conductive material (3.5 to 15 W/mK), the current carrying capacity is increased.

2. Heat dissipation or transport where other traditional methods are not feasible, such as under chip components. - Cons:

1. The thermal conductivity is not too high (compared to electroplated copper with a thermal conductivity exceeding 250W/mK), in this case a few more vias can be added to avoid the more reliable non-conductive via plug process.

2. High instability of copper pads and copper plating in via barrels. This is because of the distinct CTE (coefficient of thermal expansion) values of its surrounding laminate and conductive material. When a PCB goes through thermal cycling, the metal heats and expands faster than the surrounding laminate, which can cause fractures between the pads and via barrels and lead to open circuits.

3. By plugging is more expensive than non-conductive.

4. Demand is low, so few manufacturers can supply.

Non-Conductive Via Plugging:

Non-conductive via plugging is more commonly used, especially for “Via In Pad” processes. In general, the choice of plugging material depends on the availability, CTE value, specific design requirements and plugging machine type. Whereas, the thermoconductivity of non-conductive materials is typically around 0.25 W/mK. Non-conductive via plugging is not, as people think, passing no current or only a weak current.

- Pros:

1.It blocks the intrusion of some contaminants and solder.

2.Non-conductive via plugging is more reliable and steady. Also, these fillers have a CTE that matches the nearby laminate.

3.The non-conductive via plugging is powerful enough to supply structural support for the active pad. - Cons:

It might not be able to deal with high currents because of low thermal conductivity.

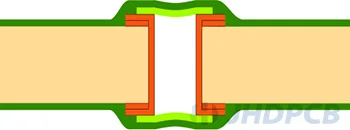

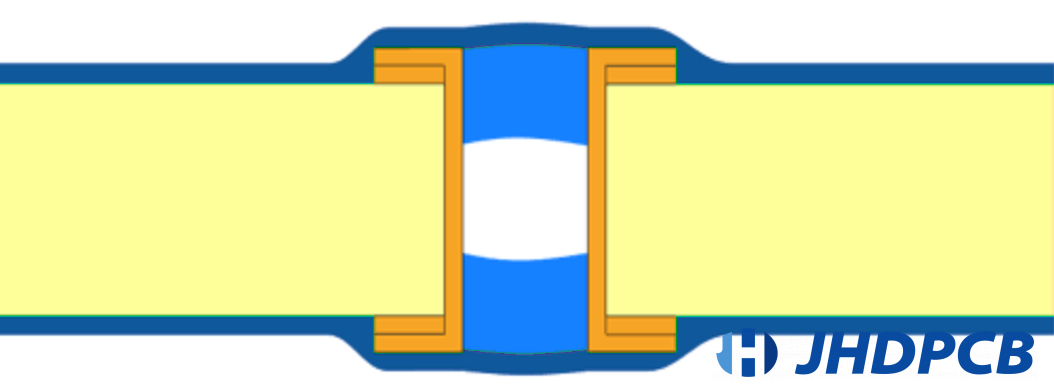

What is Via Filling?

Via filling in PCB is a technique in which the via hole is filled with epoxy. This process completely or selectively uses conductive or non-conductive epoxy as the filler material to fill vias with epoxy. Filled vias provide better assembly yields, more reliable surface mounts, and improve the reliability of PCB by reducing the possibility of trapped liquid or air in the PCB board and in the vias.

Pros and cons of filled vias.

Pros:

- Increased thermal and electrical conductivity.

- Cheaper in cost compared to via plugging process.

- Provide the shortest probable line for high frequency designs to bypath capacitors.

- Ideal if the motive is only to fill via with 100% assurance.

Cons:

- It is not fit for Via in Pad process (active via).

There are two main types of PCB via filled.

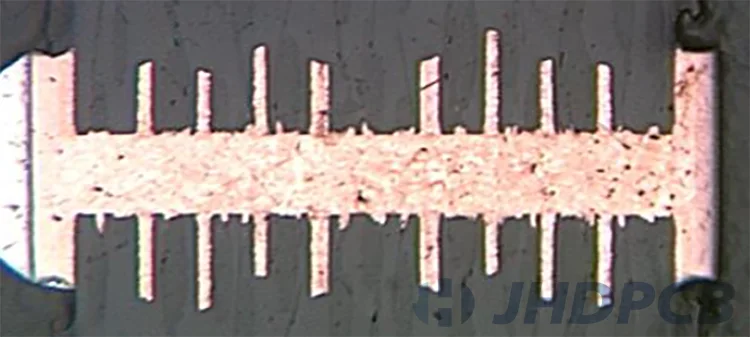

Conductive Via Fill:

Conductive via fill enhances the thermal transfer characteristics of the vias because it allows electrical signals to be efficiently transmitted from one side of the board to the other. Conductive filled vias are very helpful in conducting a large amount of heat away from the component because the conductive vias are filled with silver and copper particles distributed throughout the epoxy to provide additional thermal and electrical conductivity.

When choosing conductive epoxy for filled vias PCB, the typical materials of choice are between the DuPont or CB100the silver-coated copper particle epoxy matrices of the Tatsuto AE3030 epoxy fill. Both of them are electrically and thermally conductive when cured.

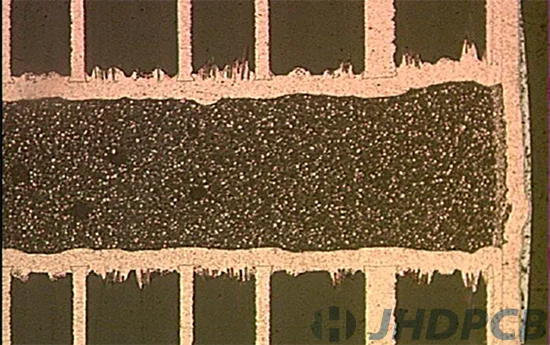

Non-conductive via fill:

Non-conductive via fill uses essentially the same process as conductive, but the purpose of this is not to conduct heat and signals, but to prevent solder or other contaminants from entering the vias. In the case of a via-in-pad, it also provides supporting structure for the copper pad coating the hole. Note that non-conductive filled vias have copper planting vias to conduct heat and power as usual.

When choosing a non-conductive epoxy for PCB via fill, Peters PP2795 epoxy is usually chosen. The previous replacement was San-Ei Kagaku PHP-900 epoxy. Regardless, both should cover your basic needs when it comes to non-conductive via fill epoxies.

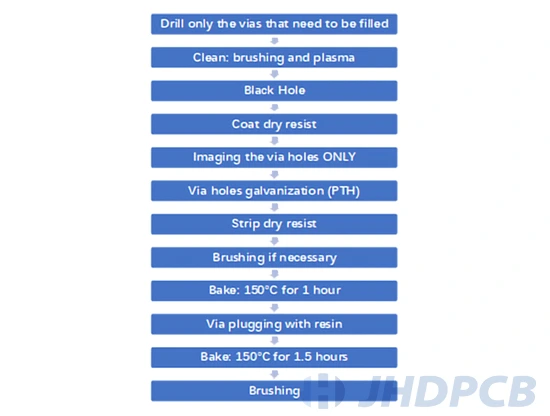

Production steps for via filling.

Via Filling with Resin: The vias to be filled are filled with a specific hole plugging resin, TAIYO THP-100 DX1 heat-curing enduring filler material, using a dedicated machine, ITC THP 30. The additional production steps required are performed prior to the 2-layer PCB production process. This will be after pressing if making multi-layers.

Outline of the additional processes:

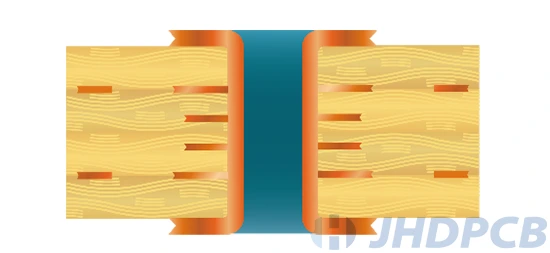

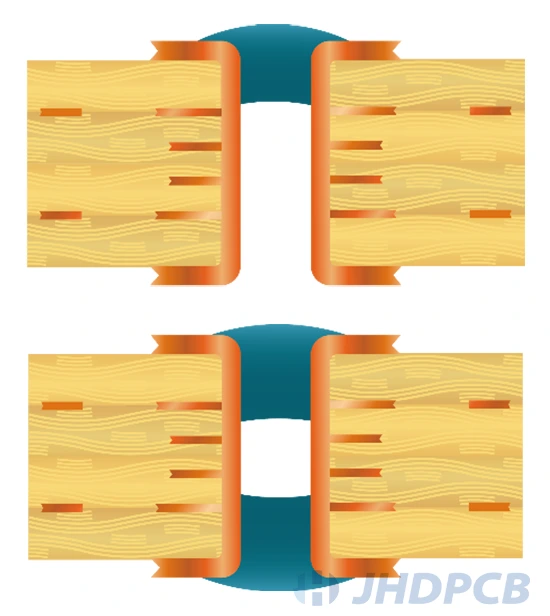

The difference between via filling and plugged vias.

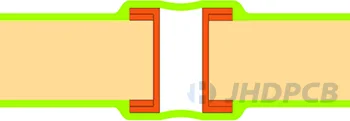

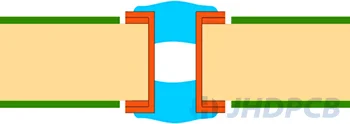

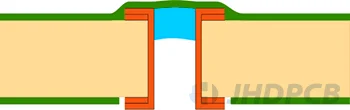

IPC-4761 clearly defines the difference between filled vias and plugged vias through the classification of protection types.

Filled vias

Plugged vias

The following shows some recommended and non-recommended types from the seven different types of via coverages:

| Recommended Via Types Protection | Not Recommended Via Types Protection |

|---|---|

IV-B Plugged & Covered Via V Filled Via VI-A Filled and Covered Via VI-B Filled and Covered Via VII Filled and Capped Via

|

III-A Plugged Via (Not Recommended Long-Term Reliability Risk) III-B Plugged Via IV-A Plugged and Covered Via |

Filled and plugged vias can enhance the PCB reliability by reducing the probability of air or liquid entrapment in vias, insuring finished product ratio through assembling. However, as can be seen from the above table, the PCB filled vias that have more advantages than plugged vias will be selected in our actual manufacturing process.

In JHD, with more than 10 years of full-series PCB manufacturing experience. We can provide you with all kinds of circuit boards with tented vias, filled holes and plugged holes as you need. We can not only ensure high-quality PCB assembly and manufacturing for you, but also get the most benefit for you. Our professional team can engage you with the finest quality after-sales and service. If you have any requirements, please contact us online freely.

We recommend that you choose a type of via coverage based on your budget and PCB quality requirements. If you don’t know which Via Covering is suitable for your board, please contact us and we will give the best advice.