Printed Circuit Board Prototype

The printed circuit board (PCB) is the foundation of every electronic device in the world today. The versatility of high-tech products determines the complexity and high performance of the PCB.

The PCB prototype is an indispensable step before a new product enters mass production. The PCB prototype can correct design defects and improve design performance at a lower cost and faster speed. In addition, it helps to avoid more problems and reduce risks in mass production. Below JHD will walk you through everything you need to know about PCB prototyping.

directory

What is a PCB Prototype Board?

PCB prototype refers to the trial production of printing circuit boards before mass production. After the electronic engineer completes the PCB circuit design, the small batch trial process sent to the PCB plant is “PCB prototype production”. The prototype pcb board is an important step in the design of new electronic products. Used to verify the executable integrity of the design.

What is Rapid PCB Prototyping Service?

Fast-forwarding PCB production refers to completing PCB production at the fastest speed during the production process. It only takes 8 hours for double-sided PCB prototype, 24 hours for small batch, 36 hours for multi-layer circuit board prototype, and 3 working days for small and medium batches. Factories based on this production time are known as fast PCB manufacturers. Click to view the PCB Quick Turn time about jhdpcb.

With the maturity of PCB manufacturing process and the improvement of supply chain management level, the production speed of PCB rapid prototyping manufacturing is getting faster and faster, and the delivery cycle is getting shorter and shorter.

What are the common PCB prototypes?

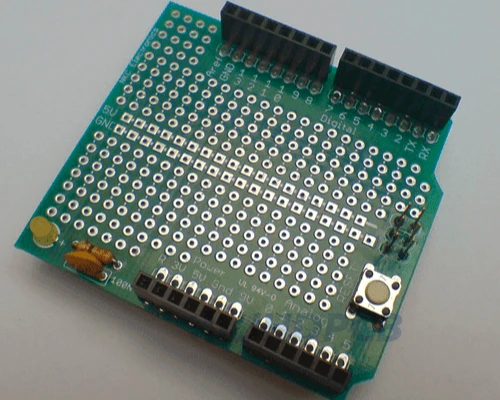

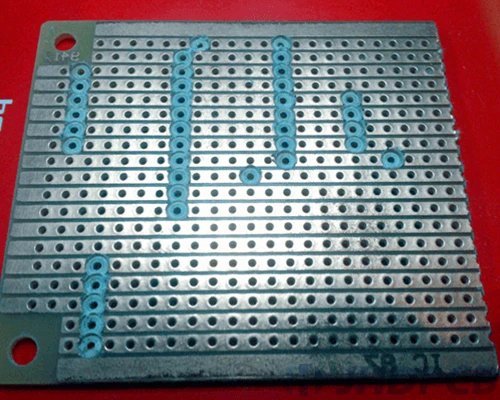

Common PCB engineering prototype boards are divided into two types: performance board and stripping board. They can be well used to plan the copper connection and component positioning of the planned board.

Performance board: Each hole of the performance board has an exclusive copper pad with an attached. This setting scheme can test component connection between the pads.

Strip board: there are many holes on the Strip board, but there are no pads on the surface. The bronze line connects the holes on the board and parallel to each other. You can also disconnect the circuit at any time.

Why is PCB prototyping so important?

The two most critical points of fast PCB prototype are speed and quality. Create a prototype board before the new PCB products are invested in large -scale production to ensure the complete implementation of the PCB prototype design. JHDPCB always follows and executes IPC Level 2 & 3 quality standards to ensure that you provide you with a reliable and fast pcb prototyping customization service. Good PCB prototype design can bring you the following help:

- Before large -scale commissioning, the early design defect was detected. Avoid large -scale bad products;

- Provide the working principle of detailed PCB circuit board;

- Test multiple designs efficiently in a more economical way;

When is PCB prototyping?

PCB prototype is so important but not every batch production needs to perform prototype proofing steps. So under what circumstances do we need to order prototype PCB service? What are the cases do not need?

- When you have a new PCB design project to prepare for landing, you should execute the prototype PCB board manufacturing;

- If your circuit board design has been produced in batches and has been used normally in electronic products. There is no need to make prototype PCB;

- If your PCB design has changed or upgraded, you should re -customize the PCB original board;

JHD can provide double -layer, 4th layers, 6th and eight -layer customized prototype test board services. In terms of materials, it is currently recommended to use FR 4 and aluminum for PCB prototypes. We will implement strict standards to provide you with fast PCB prototype services. After passing the prototype test, you can order more different materials and layers of printing circuit boards.

Why do You Need Prototyping Services?

We believe that customers who produce printed circuit boards understand that PCB prototyping is required before mass production. PCB prototype is not only to understand the quality response of products in advance, but also to reduce defects in precision manufacturing, so PCB prototype is an important link to ensure quality in advance. Of course, before prototyping, both parties must communicate in-depth details and specific parameters to facilitate the success of prototyping and lay the foundation for subsequent production.

The purpose of prototyping with four items below:

A PCB prototype can verify your circuit design and manufacturability

Circuit board design is a very complex process, especially when designing multi-layer PCBs, such as 8-layer, 10-layer, 12-layer, and even more difficult boards.

Whether the PCB circuit design and layout is reasonable and whether the designed circuit board conforms to the current manufacturing process needs to be tested through prototype trial production.

If you want to save time and money, we highly recommend doing a small amount of prototyping first. As it happens we are a professional PCB prototyping manufacturer offering rapid prototyping PCB prototype production and assembly services. If you are not sure whether you need a custom pcb prototype, you can also verify the feasibility of the preliminary review design through our free DFM first. Our professional engineers will give the best advice.

Prototype PCB can reduce the defect rate in mass production

Usually, PCB boards are processed and produced in large quantities. To ensure that all mass production runs smoothly, without quality issues, and with reduced defect rates, prototype processing is mandatory before production. After all, the processing of the PCB board needs to go through a complex processing process, and there will be no errors in each processor processing link. After the prototype is successful, the samples will be fully tested by professional technicians. The test content includes whether there are faults in the lamination, cleanliness, electrical integrity, circuit impedance and other aspects of the circuit board. After passing the professional test, it is determined that there is no problem before mass production of the PCB. At JHD, you can rest assured that we have a complete and reliable PCB testing process.

Judging the process capability of the PCB manufacturer by the PCB prototype

Through PCB prototyping, we can further understand the processing capabilities of PCB factories, especially manufacturers that have not cooperated with them before. We all know that the quality of the printed circuit board directly determines whether the electrical and electronic products can operate normally, which also stipulates that the quality of the PCB we produce must be guaranteed. Different PCB manufacturers have their own technical advantages, but there are huge differences in processing power. For example, high-end PCBs need to be done by companies with higher processing capabilities.

PCB prototyping lays the foundation for mass production

PCB prototyping is also intended to get an early look at the performance and functional response of a new product. Through prototyping, a good basis for future series production can be effectively laid, and the corresponding material costs can be calculated in advance to optimize defects. These need to be prototyped. Only through effective handling can we reduce the occurrence of unexpected problems in mass production.

From this, we can conclude that PCB prototyping is very important and necessary before it is officially put into production. This is also the first step in further cooperation with PCB manufacturers. However, there are too many factors to consider when we choose a PCB prototyping manufacturer. Reasonable price, excellent service and suitable quality suppliers are our first choice. If you are looking for such a PCB manufacturer, you can always contact us, or email us directly at sales@jhdpcb.com.

Why is a quick turn PCB prototype so fast?

There are special emergency services.

Emergency services are like a boon to customers with urgent needs. So-called expedited services require different durations for different product types. For example, single-sided and double-sided PCB rush can be completed within 8 hours at the fastest, and four-layer board rush can be completed within 24 hours. Mass production peaks can be completed within 48 hours… Whatever the product, as long as there is an urgent demand, its production rate is bound to be faster. View JHD’s regular lead times.

Strictly control the production process management.

Quick flip circuit board prototyping is a tedious process. Suppose the manufacturer fails to exercise strict management and control from order to production completion. In this case, its production efficiency may be in a low state. On the contrary, only strict process management in the production process can significantly improve production efficiency and ensure delivery speed. Click to view about JHD’s PCB quality control system.

Advanced production equipment.

How can your documents be quickly copied one by one without a copier? Therefore, having advanced automation equipment is also very important for PCB prototyping. Only with this kind of equipment can the labor productivity be significantly increased by the machine and the product delivery time can be greatly shortened. Click to view about JHD’s PCB manufacturing line.

What are the requirements for building PCB prototypes?

omplete and correct design documentation needs to be prepared before a prototyping pcb can be manufactured. This includes complete information on circuit impedance control, component designators, bill of materials (BOM), and more. Proper documentation on prototype PCBs can help make subsequent manufacturing processes more efficient. JHD makes the following recommendations:

- Develop a complete review process to ensure accuracy;

- Save time by using the original template, pay attention to editing and pruning work in a copy of the old template;

- All documentation and design drawing information match;

- The part number is updated in real time;

All production documentation errors will result in delays or errors in prototype PCB manufacturing. Be sure to ensure the integrity of the information before submitting it to the prototype pcb’s manufacturer.

What is the important information for PCB prototyping?

To submit a prototype design or get a quote for PCB prototyping services, you need to prepare some information about the design. In general, the more detail, the better – this will help you get the results you want. Here is some information you should include:

- Number of layers required

- Plate thickness

- Board size

- Copper thickness and weight

- Minimum tracking and spacing

- Minimum hole size

- Minimum annular ring

- Surface finish

- Soldermask and color

- Silkscreen legends and colors

- Drill file NC Excellon

- Drill file Tool List

What are the steps in the PCB prototyping process?

Once you’ve gathered your prototype PCB information, you can begin manufacturing. Choosing an experienced and responsive PCB manufacturer can guarantee the quality of your prototype boards. PCB prototyping is a process requiring attention to detail. Let’s discuss the process step by step.

- Draw the schematic: The first step in PCB prototyping is to draw the schematic. The schematic diagram of the PCB contains key information such as the board circuit, components, dimensions, etc. It is responsible for the outline interconnectivity of the PCB. Check out our blog for a detailed schematic guide.

- Complete design: Designers will draw detailed hierarchical diagrams in professional PCB design software based on the information provided by the schematic diagram. A complete DFM can effectively improve manufacturing efficiency and reduce costs. We will conduct a comprehensive inspection and conduct simulation tests to correct any defects.

- Bill of Materials: Build a complete bill of materials, including materials and components required for production. Clear the information describing all materials. as follows:

1. Substrate Materials: Epoxy and composite boards are used for flexible and fast PCB prototyping. It can be easily folded, cut and shaped. Metal core PCB has excellent characteristics such as high heat dissipation and high mechanical hardness, and is widely used in the market. For more pcb material types, please refer to “PCB copper clad laminate material characteristics introduction“2. Electronic components: clear component type and quantity;

3. Value: Clearly describe the specifications of each component and trace, such as: microns, ounces, ohms, farads…

4. Reference code: mark a unique identification code for each component;

5. location: the location of each component; - Trace Layout: Plan the circuit traces of the board and place electronic components. A reasonable trace layout provides complete impedance control. In this way, the integrity of the signal transmission is ensured and the influence of noise is avoided. Click to see more PCB design layout knowledge.

- Test Checks: Functional tests of the design. This includes checking component placement and connections, thermal management, routing, and electrical rules checking (ERC). Regular design checks throughout the design process can avoid overturning too much up-front work. In particular, a comprehensive inspection is carried out before putting into production to check whether there are potential problems in all aspects.

- Error Correction and Redesign: If there are any errors in the design, perform error correction. Trace connections to modify the performance of your PCB prototype. Then re-prototype with new connection traces on the template.

- Rapid prototyping: During rapid prototyping, prototypes are produced. Place the template on the plastic plate and mount the components. This is sometimes actually performed on CAD software. This is rapid manufacturing, hence the name rapid pcb prototyping.

- Standard PCB Prototyping: If you have no specific requirements for lead times, it is recommended that you perform a full prototyping process on the assembly line. This allows for more realistic verification of prototype board functionality. Fabrication processes include (but are not limited to): lamination, drilling, copper plating, imaging, etching, application of solder mask, conformal coating, surface treatment, screen printing and cutting, etc. Click to view the detailed PCB manufacturing process.

- PCB Assembly Prototype: Once the bare board and components are ready, the prototype pcb assembly can be performed. The electronic components are fixed on the circuit board prototype through a series of packaging steps such as applying solder paste – placing components – soldering.

- Functional Testing: After building a complete pcb assembly prototype, perform functional testing to check that the prototype is working as intended. If the intended functionality is met on the PCB prototype, it will move to the final product manufacturing stage.

Why choose JHD as your PCB prototype supplier?

1.Best Prototype PCB Service.

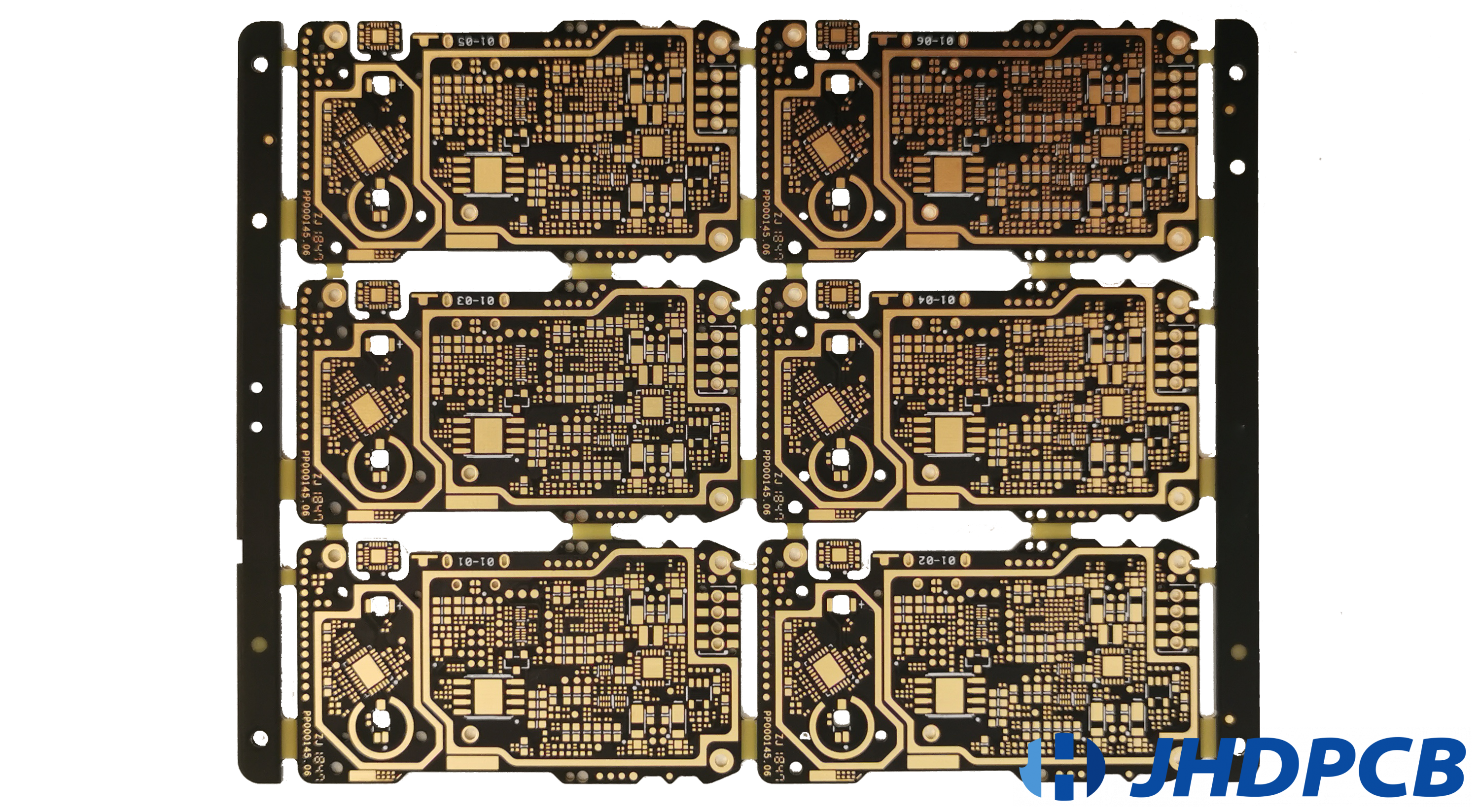

JHDPCB is one of the fast PCB manufacturers in China, which can provide PCB prototyping service and quick spin PCB prototype assembly service. We provide professional low-volume, low-cost single-layer and double-sided circuit boards as well as high-precision multilayer PCB prototyping and assembly services.

In China, most PCB factories are concentrated in Shenzhen, with a complete industrial chain. Since its establishment, JHDPCB has been committed to providing engineers, solution providers, researchers and hobbyists with high-quality, high-reliability and high-efficiency rapid PCB prototyping services.

In order to help customers shorten product development time and gain a competitive market advantage, our company continuously increases the upgrade and investment of production equipment, introduces modern production and testing equipment and software, strengthens the construction of engineering teams, and ensures the continuous improvement of the efficiency of all process.

2.Rapid PCB Prototyping.

As a professional PCB prototype service supplier, jhdpcb.com dedicates itself to offering every client excellent PCBs. Knowing the time urgency of prototypes, the cooperative manufacturers spare no effort to fabricate your PCB prototype just as quickly as 24 hours. Moreover, the experienced PCB manufacturing capabilities also present you with 100% quality assurance. Thus, you can rely on www.jhdpcb.com to get the fast turn PCB prototype.