Industrial Equipment PCB Manufacturing

Market Size and Prospect of PCB in Industrial Manufacturing Equipment.

PCB plays a vital role in industrial manufacturing equipment, it is the backbone of modern industry. From mechanical equipment to automation systems, PCBs are used in a wide range of industrial manufacturing fields. Such as robots, automation control, sensors, drives and other automation equipment. With the continuous development of technology, the scope of application of PCB continues to expand, bringing more efficient, more accurate and smarter solutions to industrial manufacturing.

At present, the market size of industrial control PCB is also expanding year by year, and its market is expected to maintain good growth in the next few years. It is estimated that by 2027, the global industrial PCB market will reach approximately US$22 billion. This forecast reflects the potential and opportunities of the future industrial PCB market.

The role and new challenges and opportunities of PCBs in industrial manufacturing equipment.

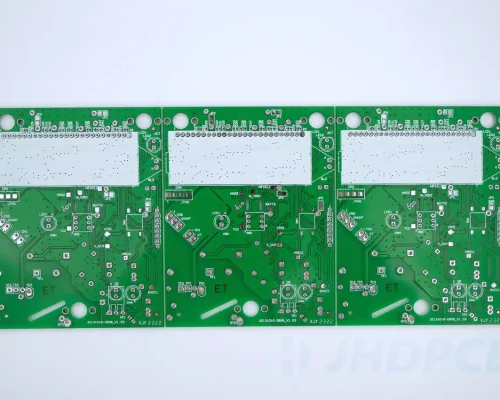

In industrial manufacturing equipment, PCB plays a vital role. As the core components of the control circuit board, they can realize various functions of the control system, such as data processing, robot control and motion control, etc. In addition, industrial PCB also has the characteristics of high reliability, high performance, high density, and strong anti-interference ability, which can meet the requirements of complex industrial environments.

With the continuous emergence of new technologies, the application range of industrial PCBs is also expanding. For example, in the era of Industry 4.0, industrial PCBs, as the core of the Internet of Things and connected devices, provide key support for the realization of smart manufacturing and digital transformation. At the same time, some emerging industries, such as new energy vehicles, drones, smart homes, etc., also pose new challenges and opportunities for industrial control PCBs.

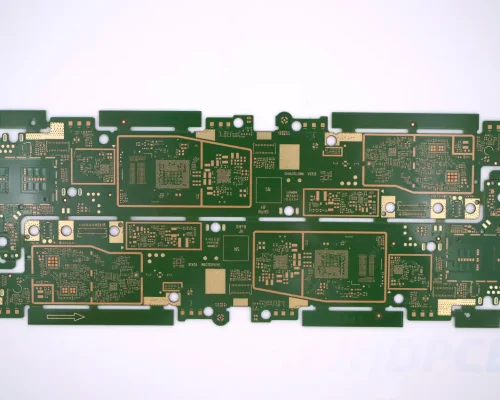

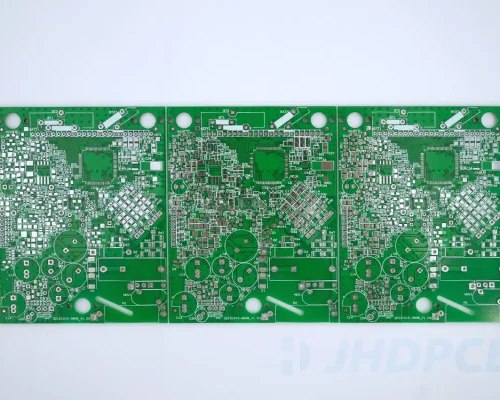

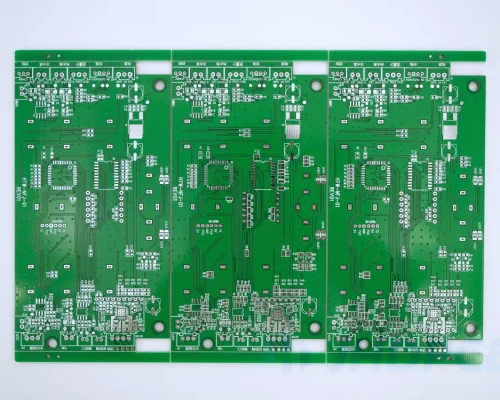

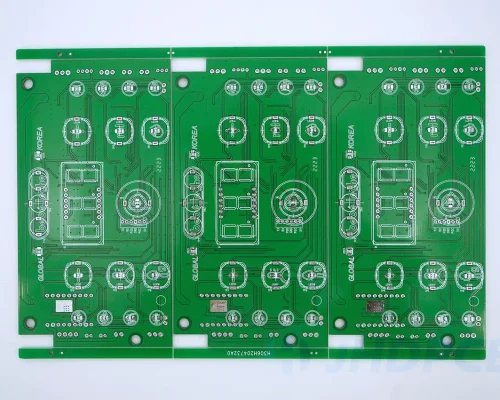

As a professional PCB manufacturer, we have advanced production equipment and technology to provide customers with high-quality industrial PCB solutions. Our products are widely used in various industrial manufacturing equipment, such as robots, automation control, sensors, etc. We continue to innovate and pursue excellence, providing customers with customized industrial PCB solutions to help customers achieve business development and success.

Development trends of PCBs in industrial manufacturing equipment.

With the rapid development of today’s industrial equipment market, more and more equipment uses PCBs in the production and manufacturing process. The following are some of the latest developments and trends of industrial control PCB, as well as related new technologies.

- Automation: More and more robots, sensors, and controllers in industrial equipment require high-quality PCBs to ensure system stability and reliability. As the demand for automation increases, PCB will play a more important role.

- Internet of Things (IoT): With the development of IoT technology, connectivity between devices and machines has become more prevalent. This leads to many new opportunities and challenges, especially in the field of industrial equipment manufacturing. The PCB plays a key role in enabling the interconnection of devices.

- Energy saving and environmental protection: On a global scale, the continuous strengthening of environmental regulations has prompted industrial equipment manufacturers to focus more on energy saving and environmental protection. The use of high-quality PCBs can reduce energy consumption and waste generation, thereby reducing environmental impact.

- New materials: With the development of PCB technology, more and more new materials are used to make PCBs. For example: FR4, ceramics, glass and other new materials. Different materials can provide different emphasis on performance.

In the future, with the advancement of Industry 4.0 and intelligent manufacturing, the application prospects of PCB in the industrial equipment industry will become broader. With the continuous advancement of industrial automation and the intelligentization of industrial equipment, the application of PCB in industrial manufacturing equipment will continue to increase. JHD continues to update and improve technology and manufacturing capabilities to meet the needs of the market and provide better solutions for industrial manufacturing equipment. We have rich experience in industrial PCB manufacturing, adopt advanced manufacturing technology and equipment, and provide customers with high-quality, high-reliability industrial control PCB manufacturing services.

Application of PCB in industrial manufacturing equipment.

- Motor Controller;

- Robot controller;

- Automated testing equipment;

- Machine tool controller;

- Motion Controller;

- Electronic weighing equipment;

- Welding controller;

- Industrial camera;

- PLC;

- HMI;

- Sensor;

- Flow meter;

- Vacuum pump controller;

- Industrial Automation Instrumentation;

- Industrial computer;

- Industrial Modular Controller;

- Industrial Wireless Module;

- Power controller;

- Solenoid valve controller;

- Temperature Controller;

- Communication Module;

- Fan controller;

- Lighting Controller;

- Power converter;

- Motor driver;

- Instrumentation;

- Circuit board tester;

- Industrial integrated circuit;

- Laser controller;

- Industrial drone;

Why choose JHD Industrial PCB

- Single-layer circuit board;

- Double-layer circuit board;

- Multi-layer circuit board;

- Flexible printed circuit board;

- Rigid-flex board;

- Ceramic plates;

- RF/microwave/high frequency circuit boards;

- Thick copper circuit board;

- High TG PCB;

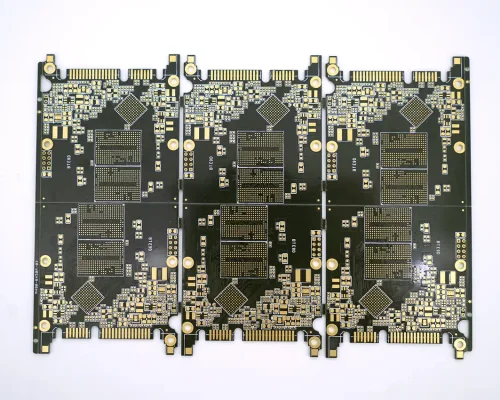

- HDI PCB;

- Up to 30 layers, up to 64 layers for samples;

- Impedance tolerance -/+5%;

- Maximum 20OZ copper thickness;

- Minimum 0.005″ mechanical drilling;

- Minimum 0.0025″ laser drilled holes;

- Blind vias/buried vias/through vias;

- Tented vias/plugged vias;

- Customized solder mask and silk screen;

- Surface/through-hole assembly;

- ISO 9001: This is a quality management system certification, which shows that the quality management system of the enterprise has been certified and can be continuously improved.

- IPC-A-600: This is a PCB manufacturing standard that specifies various requirements for PCB appearance, size, packaging, and identification.

- IPC-6012: This is a PCB manufacturing standard that specifies the special requirements required for high-reliability electronic products, such as aerospace, defense and other fields.

- IPC-6018: This is a PCB manufacturing standard that specifies the requirements for metal substrate (Metal Core PCB) manufacturing.

- UL certification: This is a safety certification that shows that the product meets safety standards and is able to work safely under specific electrical conditions.

- RoHS certification: This is an environmental certification, indicating that the product meets the requirements of the European Union’s Restriction of Hazardous Substances Directive.

- REACH certification: This is an environmental certification that indicates that the product complies with the European Union’s chemical substance registration, evaluation, authorization and restriction regulations.

- AA9100 S/B AS9100: This is a quality management system certification for the aerospace industry. They are also widely used in PCB manufacturing in other high-reliability fields, such as military, medical and industrial control, etc. These standards focus primarily on quality management and control of the production and manufacturing process to ensure that the final PCB product meets the highest quality standards.

- J-STD-001 ES: Jointly developed by IPC and JEDEC, it aims to ensure the reliability and quality of electronic assemblies. The standard covers the manufacturing process of electronic equipment, including PCB fabrication, material selection, component mounting, soldering, and inspection.

JHD strictly abides by the above standards when manufacturing industrial circuit boards for our customers. Comply with local certifications while ensuring reliable equipment operation.

- DFM and DFA checks;

- Component engineering assistance and procurement;

- Appearance inspection;

- Functional check;

- Environmental testing (thermal cycle test/thermal shock test/temperature and humidity deviation test);

- AOI report;

- Flying probe or online test report;

- Automated X-ray Inspection (AXI);

- Mock test;

- Digital test;

The industrial PCB manufactured by JHD can ensure the quality and reliability of the board through the above inspection and verification system, and improve the stability and reliability of industrial equipment.

JHDPCB’s industrial PCB manufacturing team works with you to solve the shock, vibration, extreme temperature, humidity and dust control problems that industrial equipment PCBs face, and helps customers launch industrial products with reliable technology.

In the future, we expect more industrial equipment to use PCBs in creative and diverse ways. If your company uses industrial equipment and you need printed circuit boards, or you are developing industrial equipment with new functions and would like to be supported by a reliable PCB manufacturer. JHD can help. You can submit design information on the website to customize samples or contact us online to learn more about our PCBs.

JHD Industry Control PCB