The Role And Features Of LED Light Engine

LED Light Engines are cutting-edge technology that combines light-emitting diodes (LEDs) with advanced electronic components, revolutionizing the lighting industry. LED light engines provide a multitude of benefits, including enhanced energy efficiency, extended lifespan, and the ability to customize the design. As a result, their popularity has grown significantly across a wide range of applications, spanning residential, commercial, and industrial lighting.

At JHDPCB, we understand the demand for high-quality LED Light Engines and the need for reliable manufacturing services. With our expertise in printed circuit board (PCB) fabrication and assembly, we proudly offer comprehensive solutions for LED Light Engine production.

What is an LED Light Engine?

An LED light module is basically a compact electronic circuit board with an embedded LED chip positioned at a specific location on the device. Similar to other devices that generate light, an LED light module is essential for the operation of an LED light or for transforming a conventional non-LED light into an LED light source. Numerous LED light modules are engineered to be compatible with a diverse range of fixtures, enabling convenient conversion of the lighting system in your residence or workplace.

LED light engines possess the distinct characteristic of combining electrical and mechanical components, facilitating effortless connection to luminaires and pre-existing fixtures. The electrical circuit board is responsible for generating light and is connected through wires, while the mechanical elements serve the purpose of mounting the LED light engine securely in the desired location. This dual functionality ensures both the efficient operation of the light source and the proper integration of the LED light engine into the overall lighting system.

From a technical perspective, an LED light engine can be described as nothing more than a combination of an LED driver and one or multiple LED modules, although there are various models available depending on specific lighting requirements and specifications. In certain instances, the driver is incorporated within the modules themselves. Nevertheless, numerous LED light engines consist of separate drivers and modules. Although there exist numerous manufacturers and design variations, LED light engines have contributed to the standardization of the LED industry, facilitating compatibility between products and existing lighting systems for both businesses and consumers. This standardization has streamlined supply chain management while offering a wider range of options and flexibility.

Working Principle of LED Light Engines

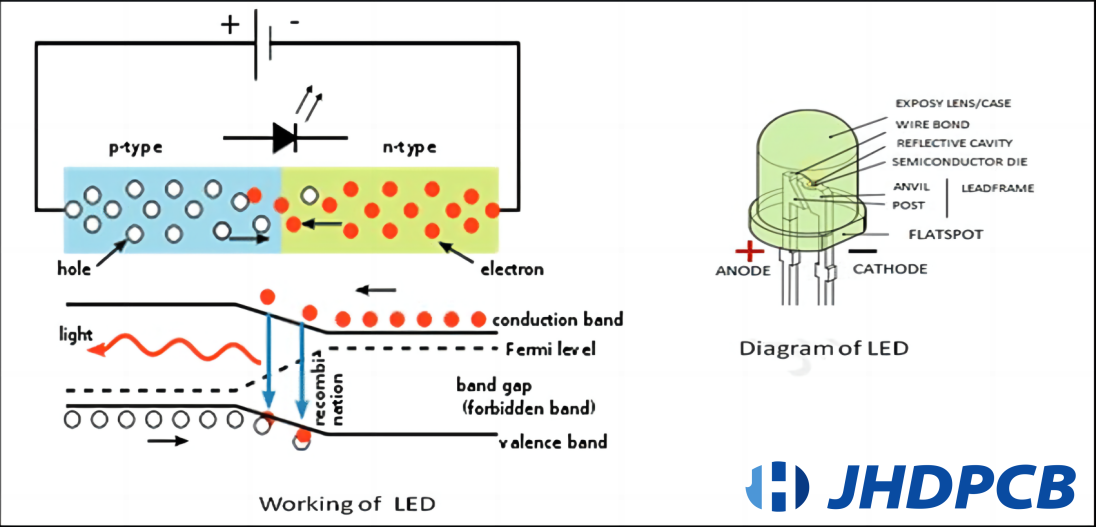

The working principle of LED light engines is based on the phenomenon of electroluminescence. Electroluminescence is the process in which light is emitted from a material when an electric current is passed through it. LED light engines are composed of numerous individual light-emitting diodes (LEDs) that generate illumination upon the application of an electric current.

The working principle of LED light engines can be summarized in the following steps:

- Electrical Current Flow: When an electrical current is applied to the LED light engine, it flows through the circuit and reaches the LEDs. The power source, which can be a battery or an AC power supply, typically supplies the required electrical current.

- Semiconductor Material: The light-emitting diodes (LEDs) within the light engine are constructed using semiconductor materials, for example, gallium nitride (GaN) or indium gallium nitride (InGaN). These materials possess distinctive characteristics that enable them to produce light when stimulated by an electric current.

- Electron Movement: Once the electrical current reaches the LED, it encounters an interface formed by distinct layers of the semiconductor material, referred to as the p-n junction. This junction comprises two segments: the p-type region and the n-type region.

- Electron and Hole Recombination: Within the p-n junction, the flow of electrical current induces the migration of electrons from the n-type region towards the junction, where they unite with positively charged carriers called holes originating from the p-type region. This process is known as electron-hole recombination.

- Energy Release: When electrons merge with holes, energy is liberated in the form of photons (particles of light). The hue of the emitted light is determined by the energy level of the photons. The specific properties of the semiconductor material, such as its bandgap, determine the energy and wavelength of the emitted light.

- Light Output: The photons generated by the electron-hole recombination process escape from the LED chip and contribute to the overall light output of the LED light engine. The light output from multiple LEDs in the light engine combines to create the desired brightness and illumination.

- Control and Management: LED light engines often incorporate additional components, such as drivers and control circuits, to regulate the electrical current, dim the light output, or provide color tuning options. These components ensure proper operation, control, and management of the LED light engine.

By utilizing the working principle of electroluminescence and the specific properties of semiconductor materials, LED light engines provide energy-efficient, long-lasting, and controllable lighting solutions for various applications.

The role of the LED light engine

The LED light engine plays a crucial role in the overall performance and functionality of LED lighting systems. It serves as the core component that generates and controls the light output. Here are the key roles and applications of LED light engines:

1. Role of LED Light Engines:

- Light Generation:

The primary role of LED light engines is to generate light. These light engines comprise multiple independent light-emitting diodes (LEDs) that produce illumination upon the transmission of an electrical current. The LEDs are carefully selected and arranged to achieve the desired brightness, color temperature, and color rendering properties. - Light Control:

LED light engines additionally offer the ability to manage diverse lighting parameters. They can be engineered to incorporate dimming functionalities, enabling users to customize the intensity of illumination based on their requirements. Advanced LED light engines may also provide color tuning options, enabling users to change the color temperature or create dynamic lighting effects. - Efficiency:

LED light engines are designed to be highly energy-efficient. LED light engine replacement, in particular, plays a significant role in maximizing energy savings. By replacing outdated or faulty LED light engines with new ones, energy efficiency can be further improved. LED light engine replacements efficiently convert a substantial proportion of electrical energy into light, minimizing inefficiencies and lowering power usage in contrast to conventional lighting sources. This enhancement guarantees optimal functionality and ensures that the lighting system operates with utmost efficiency, maximizing energy-saving capabilities. - Thermal Management:

LED light engines generate heat during operation, and effective thermal management is crucial to ensure optimal performance and longevity. LED light engines often incorporate heat sinks, thermal pads, or other cooling mechanisms to dissipate heat and maintain a stable operating temperature.

2.Applications of LED Light Engines:

General Lighting:

LED light engines are widely used in general lighting applications, such as residential, commercial, and industrial settings. They offer lighting solutions that are both energy-efficient and durable, serving as alternatives to conventional incandescent or fluorescent lighting fixtures.

Architectural Lighting:

LED light engines are extensively used in architectural lighting to highlight and enhance the aesthetics of buildings, monuments, and landscapes. They offer flexibility in terms of color control, beam angles, and dynamic lighting effects, allowing designers to create visually appealing lighting installations.

Automotive Lighting:

LED light engines are increasingly employed in automotive lighting applications. They are used in headlights, taillights, turn signals, and interior lighting due to their compact size, energy efficiency, and long lifespan. LED light engines offer enhanced visibility, improved safety, and design flexibility for automotive lighting solutions.

Display and Signage:

LED light engines are extensively employed in applications such as displays and signage. They offer high brightness, excellent color rendering, and long lifespan, making them suitable for indoor and outdoor advertising displays, digital billboards, scoreboards, and video walls.

Specialty Lighting:

LED light engines find applications in specialty lighting areas, such as horticulture, aquariums, and medical lighting. They have the flexibility to be customized, allowing for the provision of specific wavelengths or color spectrums that are specially tailored to meet the distinct demands of these applications.

12V LED Engine Room Lights:

LED light engines are also used in engine rooms of various applications, such as boats, yachts, and RVs. 12V LED engine room lights provide bright and efficient illumination in confined spaces, ensuring visibility for maintenance and inspections. These lighting systems are engineered to endure challenging conditions, such as vibrations and temperature variations, which renders them exceptionally suitable for use in engine room environments.

Overall, LED light engines play a crucial role in generating and controlling light output in various applications. They offer energy efficiency, long lifespan, and flexibility, making them a preferred choice for modern lighting solutions.

Features of LED Light Engines.

LED light engines possess several features that make them favorable lighting solutions. Here are a few of the benefits and drawbacks associated with these light engines:

Advantages:

- Energy Efficiency:

LED light engines exhibit exceptional energy efficiency in comparison to conventional lighting sources. They consume considerably less electricity while delivering equivalent or even superior levels of luminosity. - Long Lifespan:

LEDs possess a significantly extended lifespan in contrast to conventional light sources, resulting in reduced requirements for replacements and maintenance expenditures. LED light engines can endure up to 50,000 to 100,000 hours or beyond, contingent upon the caliber of the constituents utilized. - Durability:

LED light engines are solid-state devices with no delicate filaments or glass enclosures, making them resistant to shock, vibration, and temperature fluctuations. They can withstand challenging environments and are less prone to failure. - Instantaneous Lighting:

LED light engines achieve peak luminosity instantly upon being activated, obviating the necessity for any warm-up duration. This characteristic distinguishes them from specific alternative lighting technologies. - Design Flexibility:

The compact size and modular nature of LED light engines allow for versatile design possibilities in various lighting applications. They can be effortlessly incorporated into various fixtures, allowing for customization to cater to specific requirements. - Directional Lighting:

LEDs emit light in a focused direction, enabling precise control over lighting. This attribute minimizes the loss of light and enhances efficiency by directing illumination precisely to the desired areas. - Color Options:

LED light engines offer a wide range of color options, including customizable color temperatures and vibrant RGB colors, providing flexibility for different lighting requirements and ambiance.

Disadvantages:

- Initial Cost:

LED light engines generally incur a greater initial investment when compared to conventional lighting alternatives. However, the decreasing cost of LED technology over time has made them more affordable and cost-effective in the long run. - Heat Management:

LED light engines generate heat during operation, and effective heat management is essential to maintain optimum performance and avoid degradation. Proper thermal design and heat dissipation measures are crucial for their longevity. - Quality Variations:

The quality of LED light engines can vary significantly among manufacturers and product lines. It is important to choose reputable brands and reliable suppliers to ensure the performance, efficiency, and overall quality of the LED light engine. - Complex Electronics:

LED light engines contain electronic components such as drivers and control systems. While these electronics enhance functionality, they also introduce potential points of failure that may require troubleshooting or maintenance. - Color Consistency:

Maintaining consistent color temperature and color rendering across different LED light engines and throughout their lifespan can sometimes be challenging. It is crucial to select LEDs with good color consistency and implement adequate quality control measures.

Overall, LED light engines offer numerous advantages in terms of energy efficiency, longevity, design flexibility, and lighting control. However, considerations such as initial cost, heat management, and quality control should be taken into account when selecting and implementing LED light engines.

What is an LED light module?

An LED light engine module functions as a substitute for a traditional LED light bulb. LED lights operate by utilizing light-emitting diodes, which function as a type of semiconductor. When an electric voltage is applied, these diodes produce packets of light called photons.

While all LEDs utilize the same technology, LED light modules present a distinct visual contrast compared to conventional LED light bulbs. In contrast to the customary bulb form, LED light modules consist of a circuit board with one or multiple light-emitting diodes arranged on it. These boards can adopt various shapes, including circular, rectangular, linear, square, or star configurations. Certain modules, such as flexible LED strip modules, offer the flexibility of being cut and rearranged for personalized applications.

What is the difference between LED light engine and LED module?

LED light engine and LED module are two different components used in LED lighting systems. Here are the differences between them:

1.Function:

- LED Light Engine: A LED light engine refers to a complete system that includes the LED chips, driver circuitry, optics, and heat management components. It is a self-contained unit that generates and controls light output.

- LED Module: An LED module is a removable component that typically consists of one or more LED packages mounted on a circuit board. It usually contains only the LEDs and minimal driver circuitry.

2.Integration:

- LED Light Engine: A LED light engine is highly integrated and self-contained, designed to provide a ready-to-use lighting solution. It incorporates all the necessary components for generating light, including the power supply and thermal management system.

- LED Module: An LED module is a modular and replaceable part that requires integration into a larger lighting system. It needs to be connected to an external power supply and may require additional components such as heat sinks or lenses.

3.Customization:

- LED Light Engine: LED light engines are often standardized products with limited customization options. They are mass-produced to meet specific lighting specifications and are not easily customizable.

- LED Module: LED modules offer more flexibility in terms of customization. They can be tailored to specific requirements by adjusting the number and type of LEDs, circuit design, or optics.

4.Application:

- LED Light Engine: LED light engines are commonly used in applications where a complete lighting solution is needed, such as streetlights, downlights, or high-bay lights. They offer compatibility with both indoor and outdoor lighting fixtures, making them versatile for various lighting applications.

- LED Module: LED modules are frequently used in applications where modular lighting is required, such as signage, display lighting, or linear lighting. They are frequently employed as fundamental components for constructing expansive lighting systems.

It is crucial to emphasize that the interpretation and application of these terminologies can fluctuate, potentially resulting in divergent connotations based on the specific situation and field.The definitions provided here represent the general understanding of LED light engine and LED module differentiations.

Factors to Consider When Choosing LED Light Engines

When choosing LED light engines, it is vital to consider several important factors. These factors will help ensure that the LED light engines meet your specific requirements and provide optimal performance. Here are some key factors to consider:

1.Light Output and Efficiency:

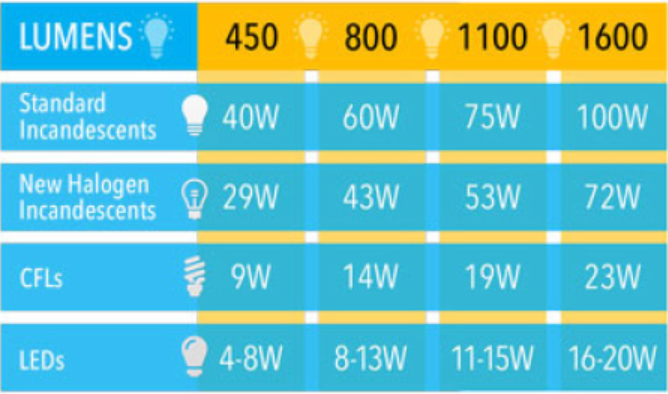

When considering the light output and efficiency of an LED light engine, it is important to look at specifications such as lumens and efficacy. Lumens refer to the amount of light emitted by the LED light engine, while efficacy refers to the energy efficiency of the light engine.

Lumens signify the intensity of the light engine. The greater the lumen value, the more radiant the light emission.It is important to consider the desired light output for the specific application or space where the LED light engine will be used. For example, a higher lumen value may be required for outdoor lighting or large commercial spaces, while a lower lumen value may be sufficient for residential or accent lighting.

Efficacy, on the other hand, refers to the energy efficiency of the LED light engine. It is measured in lumens per watt (lm/W) and indicates how much light output is achieved per unit of electrical power consumed. A higher efficacy value means that the LED light engine is more energy-efficient, as it produces more light output for the same amount of energy consumed.

When selecting an LED light engine, it is important to find a balance between the desired light output and energy efficiency. A higher lumen value may provide brighter lighting but may consume more energy, while a lower lumen value may be more energy-efficient but may not provide sufficient brightness. It is essential to consider the specific lighting requirements and energy-saving goals for the application to make an informed decision.

Additionally, it is worth noting that advancements in LED technology have led to increased light output and improved efficacy over the years. Therefore, it is recommended to choose LED light engines with higher lumen values and efficacy ratings to ensure optimal brightness and energy efficiency.

2.Color Temperature and Color Rendering:

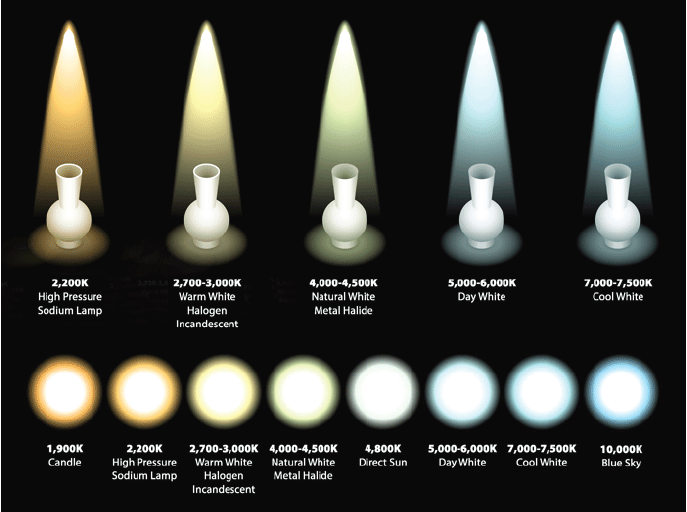

When considering the color temperature and color rendering of an LED light engine, it is important to determine the desired color temperature and color rendering index (CRI) for the specific application.

Color temperature pertains to the perceived chromaticity of the light discharged by the LED light engine. It is gauged in Kelvin (K) and classifies the light as warm, neutral, or cool. Warm light (usually around 2700K-3000K) exhibits a yellowish or reddish tint, resembling the hue of incandescent bulbs. Neutral light (around 3500K-4000K) appears more white and is often used in commercial or office spaces. Cool light (around 5000K-6500K) has a bluish tint and is often used in outdoor or industrial lighting.

The desired color temperature depends on the specific application and the atmosphere or mood you want to create. For example, warm light is often preferred for residential or hospitality settings as it creates a cozy and inviting ambiance. On the other hand, cool light is commonly used in areas where visibility and concentration are important, such as offices or retail spaces.

Color rendering index (CRI) is an additional crucial aspect to take into account. It quantifies the capacity of the light source to faithfully reproduce colors in comparison to a standard light source, such as natural daylight. The color rendering index (CRI) is evaluated on a spectrum ranging from 0 to 100, where higher values indicate superior color rendering. A CRI of 80 or higher is typically regarded as satisfactory, while a CRI of 90 or higher is distinguished as exceptional.

A heightened CRI holds significant importance in contexts where color precision is critical, such as in art galleries or retail stores. It guarantees that colors appear vivid and faithful to their authentic representation. However, in some cases, such as outdoor or industrial lighting, where color accuracy is less important, a lower CRI may be acceptable to prioritize other factors such as energy efficiency.

To sum up, when choosing an LED light engine, it is crucial to take into account the preferred chromaticity and color rendering index (CRI). The choice of color temperature will affect the mood and atmosphere of the space, while the CRI will impact the accuracy and quality of the colors rendered by the light engine. It is recommended to choose a color temperature and CRI that align with the specific application requirements and desired lighting effects.

3.Dimming Capability:

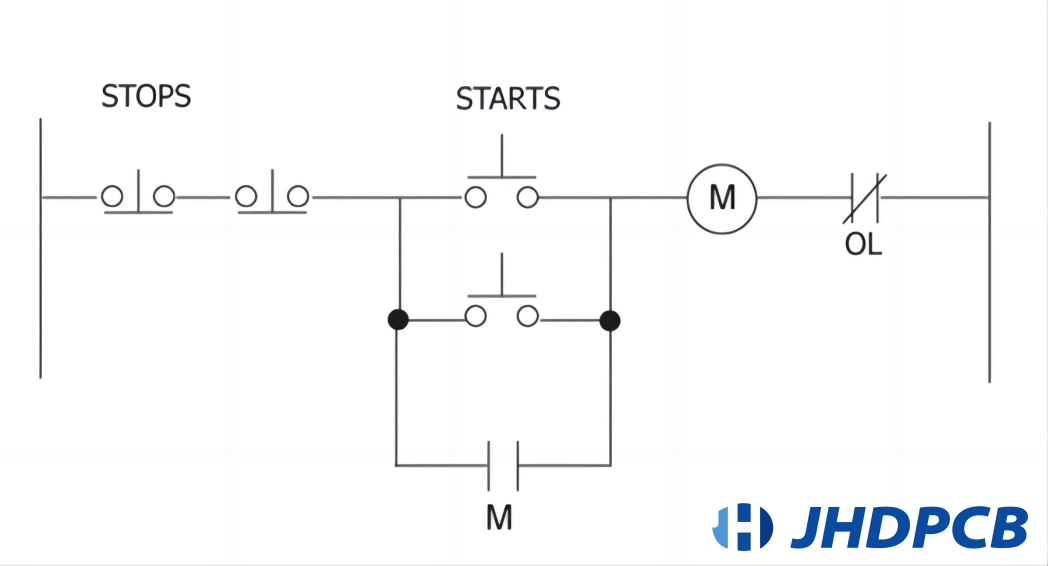

If dimming functionality is required for the LED light engine, it is important to check if it is compatible with the desired dimming method. There are different dimming methods available, such as 0-10V, PWM (Pulse Width Modulation), and DALI (Digital Addressable Lighting Interface).

First, determine the desired dimming method for your application. For example, 0-10V dimming is a commonly used method where the light output is controlled by varying the voltage supplied to the LED light engine. PWM dimming adjusts the light output by rapidly switching the LED on and off at different duty cycles. DALI serves as a digital communication standard that enables individualized control and dimming of every LED light engine within a network.

Next, check if the LED light engine you are considering is compatible with the chosen dimming method. Manufacturers usually provide information about dimming compatibility in their product specifications. Ensure that the LED light engine supports the desired dimming method to ensure proper functionality.

It is also important to consider the dimming range and performance of both the LED light engine and the check engine light LED. The dimming range refers to the range of light output that can be achieved through dimming. Some LED light engines may have a wide dimming range, allowing for a significant reduction in light output, while others may have a more limited range.

Additionally, consider the dimming performance, including the smoothness of dimming transitions and any potential flickering or color shift that may occur at lower light levels. This information is often provided by manufacturers or can be found in product reviews.

In summary, if dimming functionality is required, ensure that the LED light engine is compatible with the desired dimming method (e.g., 0-10V, PWM, DALI). Verify that the dimming range and performance of both the LED light engine and the check engine light LED meet your specific needs. This will guarantee that you can attain the intended level of command and atmosphere in your lighting implementation.

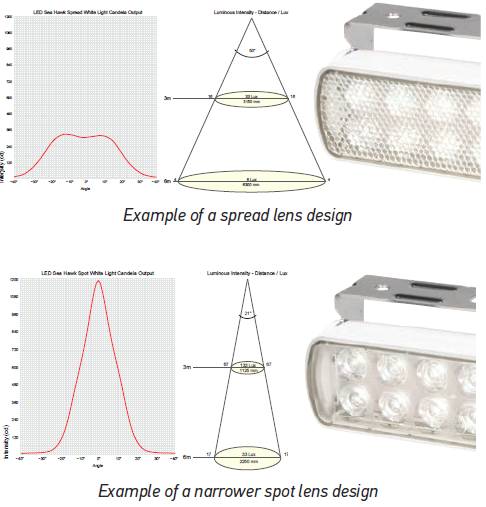

4.Beam Angle and Distribution:

The beam angle and distribution pattern of an LED light engine play a crucial role in determining how the light is spread and focused. This is important for achieving the desired lighting effect and coverage in a specific application.

The beam angle pertains to the angular extent at which the light radiates from the LED light engine. It dictates the dispersion of the light and the width or narrowness of the beam. A narrow beam angle, typically around 15-30 degrees, concentrates the light in a specific direction, providing a more focused and intense illumination. This is ideal for accent lighting or spotlighting specific objects or areas.

On the other hand, a wide beam angle, usually around 60-120 degrees or more, spreads the light over a larger area, providing a more diffuse and uniform illumination. This is suitable for general lighting applications where a broad coverage is desired, such as in large rooms or outdoor spaces.

The distribution pattern of the light refers to how the light is distributed within the beam angle. Different LED light engines may have different distribution patterns, such as symmetrical, asymmetrical, or adjustable distribution. Symmetrical distribution provides an even spread of light in all directions, while asymmetrical distribution focuses the light more in one direction, such as for wall washing or pathway lighting. The capability of customizable distribution permits versatility in aiming the light towards particular regions or objects.

When selecting an LED light engine, consider the specific lighting requirements of your application. Decide whether achieving the intended lighting effect and coverage requires a narrow or broad beam angle. Additionally, consider the distribution pattern that best suits your needs, whether it is symmetrical, asymmetrical, or adjustable.

It is also worth noting that some LED light engines offer the ability to adjust the beam angle or distribution pattern, allowing for customization and adaptability to different lighting scenarios.

In conclusion, the beam angle and distribution pattern of an LED light engine are important factors to consider when selecting the right lighting solution for your application. Understanding the specific requirements and desired lighting effects will help you choose an LED light engine that provides the optimal beam angle and distribution pattern to meet your needs.

5.Lifetime and Reliability:

When evaluating the rated lifetime and reliability of an LED light engine, it is important to consider factors such as the L70 rating and overall lifespan. The L70 rating signifies the duration in hours until the light intensity decreases to 70% of its initial value. A higher L70 rating signifies a longer lifespan and better performance over time.

LED light engines with a longer rated lifetime offer several benefits. First and foremost, they decrease costs related to maintenance and replacement since they necessitate fewer substitutions throughout their lifespan. This is particularly advantageous in applications where access to the light fixtures is difficult or costly.

Additionally, a longer lifespan enhances the dependability of the LED light engine. It ensures consistent and reliable performance throughout its rated lifetime, minimizing the risk of premature failures or significant degradation in light output.

When assessing the rated lifetime and reliability of an LED light engine, it is recommended to look for information provided by the manufacturer. This might encompass the L70 rating, which signifies the duration in hours until the light intensity decreases to 70% of its initial value. Manufacturers often provide this information in product specifications or technical datasheets.

It is also advantageous to take into account the reputation and historical performance of the manufacturer. Well-established and esteemed manufacturers are more inclined to produce LED light engines with dependable functionality and extended durations of use.

To conclude, assessing the rated lifespan and dependability of an LED light engine is essential in guaranteeing sustained effectiveness and economical value in the long run. Look for information such as the L70 rating, which indicates the number of hours until the light output depreciates to 70% of its initial value. A longer lifespan and enhanced dependability will result in reduced expenditures on maintenance and replacement, making it a worthwhile investment for your lighting application.

6.Compatibility and Integration:

To ensure seamless integration of an LED light engine into your existing fixtures, luminaires, or lighting systems, it is important to consider compatibility in terms of dimensions, installation options, and electrical connectivity.

Dimensions: Check the physical dimensions of the LED light engine and compare them to the available space within your fixtures or luminaires. Ensure that the LED light engine fits properly without any modifications or compromises to the structure or aesthetics of the existing lighting setup.

Installation Alternatives: Consider the installation options provided by the LED light engine. Some LED light engines may offer different mounting options, such as recessed, surface-mounted, or pendant installation. Choose an LED light engine that offers installation alternatives that are compatible with your existing fixtures or luminaires.

Electrical Connectivity: Verify the electrical connectivity requirements of the LED light engine and ensure compatibility with your existing lighting system. Check factors such as voltage, current, and wiring configurations. If needed, seek advice from a certified electrician to ensure appropriate electrical compatibility and secure installation.

It is also worth noting that some LED light engines may come with additional features or accessories that facilitate integration with existing fixtures or lighting systems. For example, some LED light engines may offer compatibility with standard lighting control protocols, such as 0-10V, DALI, or PWM, allowing for easy integration with existing lighting control systems.

When selecting an LED light engine, carefully review the product specifications, installation instructions, and compatibility information provided by the manufacturer. If you have any doubts or questions regarding compatibility, it is recommended to consult with the manufacturer or a lighting professional for guidance.

In summary, ensuring compatibility with your existing fixtures, luminaires, or lighting systems is essential when selecting an LED light engine. Consider dimensions, installation alternatives, and electrical connectivity to achieve effortless integration and avoid any compatibility issues.

7.Thermal Management:

Thermal management is a crucial aspect to consider when evaluating LED light engines. LED light engines generate heat during operation, and effective thermal management is essential to ensure proper operation and longevity of the product.

When assessing the thermal management capabilities of an LED light engine, it is advisable to look for features that facilitate heat dissipation. Some key features to consider include:

Heat sinks: Heat sinks are specifically engineered to absorb and disperse heat away from the LED light engine. They offer an expanded surface area for heat dissipation and aid in preserving optimal operating temperatures. Look for LED light engines that incorporate efficient and well-designed heat sinks.

Thermal pads or interface materials: These materials help improve heat transfer between the LED light engine and the heat sink or other cooling components. They provide a thermal interface with low thermal resistance, ensuring effective heat dissipation.

Ventilation or cooling mechanisms: Some LED light engines may incorporate additional cooling mechanisms such as fans, vents, or other active cooling methods. These features enhance heat dissipation and help maintain lower operating temperatures.

It is important to note that the thermal management capabilities of an LED light engine should be designed to handle the specific heat load generated by the LEDs. The manufacturer’s specifications and recommendations should be followed to ensure proper thermal management and avoid overheating issues.

When selecting an LED light engine, review the product specifications, technical datasheets, or consult with the manufacturer to understand the thermal management features and capabilities of the product. This will help ensure that the LED light engine can effectively dissipate heat and operate within safe temperature limits, leading to improved performance and longevity.

In conclusion, considering the thermal management capabilities of an LED light engine is crucial to ensure proper operation and longevity. Look for features such as heat sinks, thermal pads, and ventilation or cooling mechanisms that facilitate effective heat dissipation. Following the manufacturer’s recommendations and specifications will help ensure optimal thermal management and reliable performance of the LED light engine.

8.Certifications and Standards:

Checking if the LED light engine meets relevant certifications and standards is an important step in ensuring its safety, performance, and energy efficiency. Here are some widely acknowledged certifications and benchmarks to take into account:

UL (Underwriters Laboratories): UL is a highly reputable certification body that conducts thorough testing and certifies products for their safety. Look for LED light engines that have been UL listed or UL recognized, indicating that they meet the required safety standards.

DLC (DesignLights Consortium): DLC is a certification program that focuses on energy efficiency and performance of LED lighting products. LED light engines that are DLC listed have undergone testing and meet specific criteria for energy efficiency, light output, and other performance factors. DLC listings are often required for utility rebates and incentives.

Energy Star: Energy Star is an optional certification initiative that prioritizes energy efficiency. LED light engines that bear the Energy Star emblem have undergone testing and comply with designated energy efficiency standards. Securing Energy Star certification serves as a reliable indication of their energy-conserving capabilities.

CE (Conformité Européene): CE marking is a certification that indicates compliance with European Union safety, health, and environmental protection standards. While not specific to LED light engines, the CE mark is often required for products sold in the European market.

In addition to these certifications, it is also beneficial to check if the LED light engine complies with other relevant standards or regulations specific to your region or application. As an instance, within the United States, the Federal Communications Commission (FCC) oversees and governs the emission of electromagnetic interference (EMI). Ensuring compliance with relevant standards and regulations can help ensure the quality, safety, and performance of the LED light engine.

When evaluating LED light engines, look for information about certifications and standards in the product specifications or documentation provided by the manufacturer. If in doubt, you can contact the manufacturer directly or consult with a lighting professional to verify the certifications and standards that the LED light engine meets.

In summary, checking if the LED light engine meets relevant certifications and standards is important for ensuring safety, performance, and energy efficiency. Look for certifications such as UL, DLC, Energy Star, or CE to ensure compliance with industry-recognized standards. Additionally, consider any regional or application-specific standards that may be relevant.

9.Cost and Return on Investment:

Evaluate the upfront cost of the LED light engine and consider the potential energy savings and maintenance cost reductions over its lifetime. Compute the return on investment (ROI) to evaluate the product’s long-term cost efficiency.

10.Manufacturer and Warranty:

Conduct thorough investigation into the manufacturer’s credibility and historical performance. Consider the warranty offered for the LED light engine, as it provides assurance and support in case of any issues.

By thoroughly evaluating these aspects, you can choose the LED light engines that best match your particular lighting requirements and attain peak performance and efficiency.

FAQ of LED Light Engines

What is the difference between an LED light engine and a traditional lighting fixture?

LED light engines are different from traditional lighting fixtures in several ways. LED light engines are composed of a combination of separate LEDs that generate illumination upon the application of an electrical current. They offer energy efficiency, longer lifespan, and greater flexibility in terms of color control and dynamic lighting effects. Traditional lighting fixtures, on the other hand, typically use incandescent or fluorescent bulbs, which are less energy-efficient and have shorter lifespans. LED light engines also have a more compact design, allowing for easy integration into various lighting applications.

How do LED light engines provide color control?

LED light engines provide color control through various methods. One common method, known as the RGB LED light engine, is by using RGB (Red, Green, Blue) LEDs, which can be individually controlled to produce a wide range of colors.By manipulating the strength of each individual color, it becomes possible to attain an array of tones and variations. Another method is by using phosphor-converted LEDs, where a blue LED chip is coated with a phosphor material that converts the blue light into a desired color. Additionally, LED light engines can be equipped with control circuits and drivers that allow for precise color tuning and dynamic color-changing effects.

Is it feasible to employ LED light engines for underwater lighting purposes?

Certainly, LED light engines are viable for utilization in applications involving underwater lighting. They are often encapsulated or sealed in waterproof housings to protect them from water damage. LED light engines with high IP (Ingress Protection) ratings, such as IP68, are specifically designed to withstand submersion in water. These waterproof LED light engines are commonly used in swimming pools, fountains, aquariums, and other underwater lighting installations.

How are LED light engines used in horticulture lighting?

LED light engines are widely used in horticulture lighting to provide the specific light spectrum needed for plant growth and development. LED light engines have the capability to be tailored in order to emit particular light wavelengths, such as red and blue, which play a crucial role in the process of photosynthesis. By controlling the light spectrum and intensity, LED light engines help optimize plant growth, increase crop yields, and enable year-round cultivation in indoor or greenhouse settings. Additionally, LED light engines offer energy efficiency and long lifespans, making them a preferred choice for horticultural lighting systems.

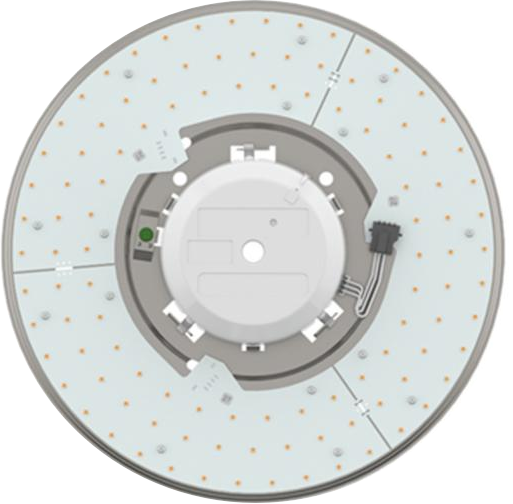

Where are circular LED light engines commonly used?

Circular LED light engines are utilized in a diverse range of environments and contexts. They are commonly used in downlights for overhead and focused illumination, in track lighting systems for adjustable lighting solutions, in architectural lighting to accentuate building features, and in decorative fixtures to create visually appealing lighting effects.

What are LED engine lights?

LED engine lights are meticulously engineered lighting fixtures that are specifically designed to deliver targeted illumination for the engine compartments of vehicles. These lights are expertly crafted to provide unrivaled brightness and clarity, ensuring optimal visibility for maintenance and repairs in the engine area. With their specialized design and purpose, LED engine lights play a vital role in enhancing safety, efficiency, and precision when working on vehicle engines.

What are the benefits associated with the utilization of fiber optic systems incorporating LED light engines?

LED light engine fiber optic systems offer precise, focused, and uniform illumination. They provide design flexibility, as the fiber optic cables can be easily routed and arranged for various lighting effects. These systems demonstrate energy efficiency as a result of the diminished power usage attributed to LEDs’ low power consumption. Additionally, they eliminate electric shock hazards as there is no direct electricity transmission through the fiber optic cables.

What is the process for implementing LED light engine retrofit?

The process for implementing LED light engine retrofit involves several steps. First, assess the existing lighting fixture to determine its compatibility with LED retrofit kits. Then, choose appropriate LED light engine modules that fit the fixture. Next, turn off power to the fixture and remove the old light source. Install the LED module into the fixture, making necessary electrical connections. Secure the module in place, restore power, and test the lighting system. Ensure all safety measures are followed throughout the retrofitting process.

At present, the LED light engine market is undergoing a period of swift progress and is anticipated to sustain its accelerated expansion in the foreseeable future. With the increasing demand for energy saving, environmental protection and high-quality lighting, the application range of LED technology will be further expanded. As a professional electronics manufacturing services company, JHDPCB is committed to providing high quality PCB and electronics assembly solutions for the LED light engine market. We have advanced production equipment and professional team, according to customer needs, customized production of various types of LED light engine. If you have a need for LED light engine, we sincerely invite you to contact us, we will be happy to provide you with the best quality products and services.