Fully Understand The JST Connector: Type, Term…

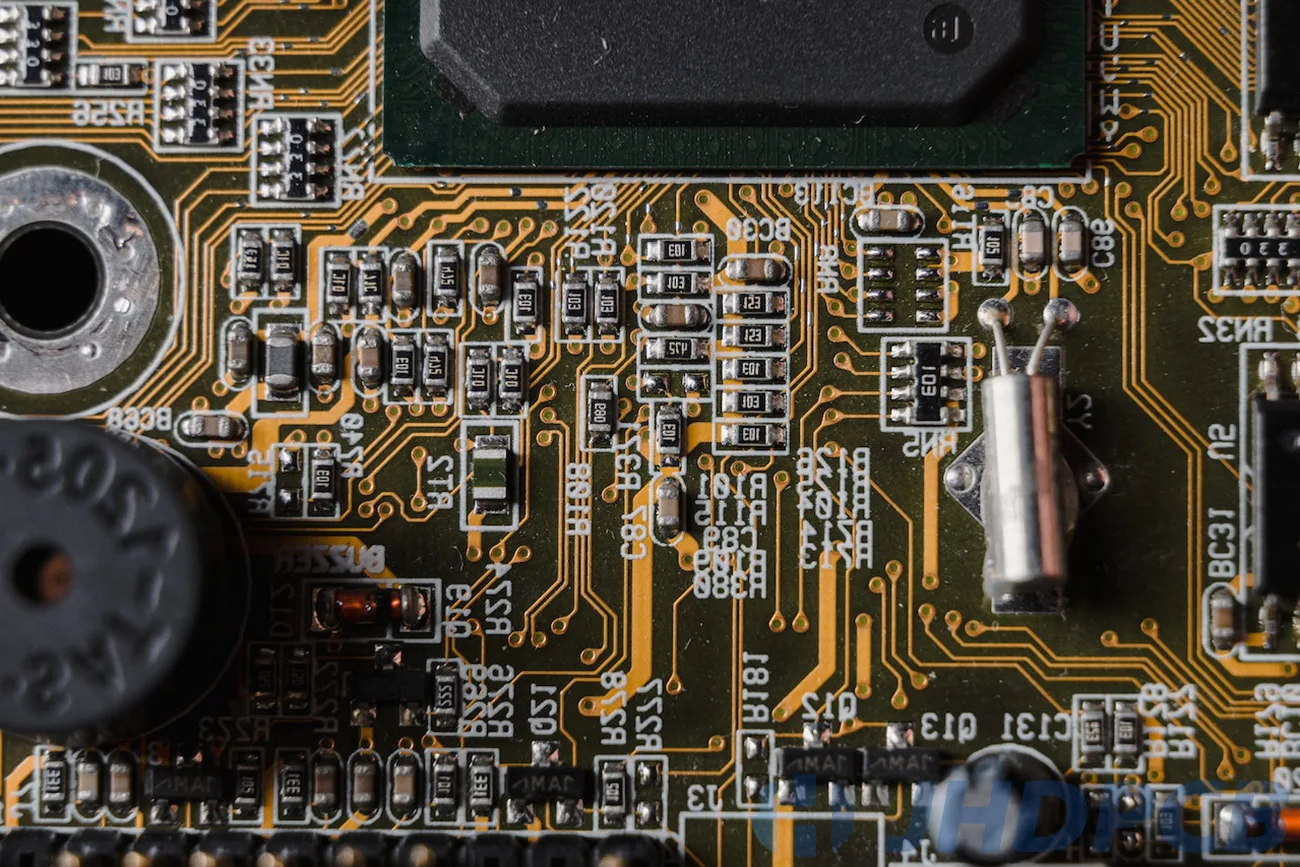

JST connector is widely recognized for their compact size, reliability, and versatility in the electronics industry. These connectors play a crucial role in establishing secure and efficient electrical connections in various applications, ranging from consumer electronics to automotive and industrial equipment.

At JHDPCB, we are a leading PCB manufacturing and assembly company with comprehensive capabilities to support the integration of JST connectors into electronic products. With state-of-the-art facilities and an experienced team, we offer services such as PCB design, fabrication, and assembly, ensuring seamless integration of JST connectors to meet the highest industry standards. Our expertise extends to various industries, providing reliable and customized solutions for consumer electronics, automotive electronics, and industrial equipment. We prioritize customer satisfaction, delivering high-quality products and services with efficient turnaround times, competitive pricing, and exceptional customer support. Trust JHDPCB as your partner for JST connectors and PCB assembly, and experience the reliability and excellence we bring to your electronic products. Reach out to us now for a conversation regarding your project specifications.

What is a jst connector?

A JST connector kit is a comprehensive package that includes various types of electrical connectors following the blueprint principles formulated by J.S.T. Mfg. Co., also recognized as Japan Solderless Terminal. These connectors are extensively employed in the electronics sector and are acknowledged for their petite dimensions, dependability, and convenience. A JST connector kit provides users with a variety of connector options, allowing them to easily connect different electronic components and devices with ease and reliability.

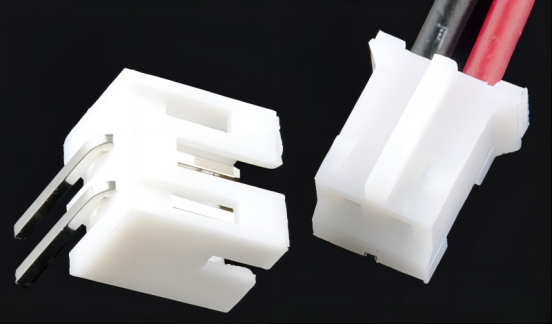

JST connectors encompass a correspondingly distinct pair of connectors, one male and one female, which can be effortlessly connected and separated. They are typically utilized for establishing electrical connections between constituents on printed circuit boards (PCBs) or between PCBs and external apparatus. These connectors present a casing that firmly secures the contacts while supplying insulation and mechanical safeguarding.

JST connectors are available in diverse series and pitches, which pertain to distinct groups and pin-to-pin intervals. This assortment enables compatibility with various applications and demands. They can be procured in assorted dimensions, encompassing micro-sized connectors with a limited number of pins, as well as larger connectors with multiple pins.

These connectors are frequently tailored for specific intentions and environments. For instance, there exist water-resistant JST connectors or those possessing high-temperature resistance, rendering them appropriate for employment outdoors or in industrial settings.

JST connectors find widespread usage in an extensive array of electronic devices and systems, encompassing consumer electronics, automotive electronics, industrial equipment, medical devices, and more. They enjoy particular prominence in applications where space is at a premium, and a dependable electrical connection is of utmost importance.

In general, JST connectors are esteemed for their quality, flexibility, and compatibility. Their standardized design and wide accessibility contribute to their popularity as a preferred option for interconnecting diverse components within electronic systems.

Characteristics of JST Connectors:

- Small Size:

JST connectors are known for their compact size, which makes them suitable for applications where space is limited. - Reliable Connectivity:

These connectors provide a secure and reliable electrical connection, ensuring efficient power transfer and signal transmission. - Easy to Use:

JST connectors are engineered for convenient connection and disconnection, enabling swift and trouble-free assembly and disassembly. - Variety of Series and Pitches:

JST connectors come in various series and pitches, providing compatibility with different applications and requirements.

Advantages of JST Connectors:

- Standardized Design:

JST connectors adhere to industry standards, ensuring compatibility and interchangeability with other components and systems. - Versatility:

These connectors can be used in a wide range of electronic devices and systems, making them suitable for various applications. - Wide Availability:

JST connectors are widely available and can be easily sourced from electronics suppliers, making them convenient for manufacturers and hobbyists. - Cost-Effective:

JST connectors are commonly budget-friendly, providing an economical option for electrical connections. - Reliability:

JST connectors are designed to provide a reliable and consistent electrical connection, even in demanding environments. Frequently, they are manufactured using premium materials that exhibit resistance to temperature fluctuations, vibrations, and moisture. - Easy Installation:

JST connectors are designed for easy installation and removal, making them user-friendly and convenient for assembly and maintenance purposes.

Disadvantages of JST Connectors:

- Limited Current Capacity:

Due to their small size, JST connectors may have limitations in handling high current loads. They are more suitable for low to moderate power applications. - Limited Compatibility:

JST connectors may not be compatible with other connector types, requiring the use of adapters or converters in certain situations. - Limited Mating Cycles:

Some JST connectors may have a limited number of mating cycles, meaning they can only be connected and disconnected a certain number of times before their reliability and performance are compromised. - Limited Wire Gauge Options:

JST connectors may have limitations in accommodating larger wire gauges, which may restrict their use in applications requiring thicker wires.

In general, the electronics industry extensively employs JST connectors due to their compact dimensions, reliability, and simplified installation process. Nonetheless, it is essential to consider their limitations in terms of current capacity and compatibility while selecting them for specific applications.

The Applications of JST Connectors

JST connectors demonstrate versatility and find extensive utilization in diverse applications across various industries. From consumer electronics to automotive, medical devices to aerospace, JST connectors play a crucial role in providing secure and reliable connections for electrical components. They are recognized for their robustness, user-friendliness, and adaptability to a diverse array of devices. Let’s delve into some prevalent implementations of JST connectors in greater depth

1. Personal gadgets:

JST connectors are frequently employed in a multitude of personal electronic devices like mobile phones, tablets, notebooks, and digital cameras. They are used for connecting internal components like displays, batteries, and sensors.

2. Automotive sector:

JST connectors find extensive application in the automotive industry for establishing electrical connections among components like sensors, actuators, and control modules. They ensure a dependable and steadfast linkage even in demanding operating conditions.

3.Industrial equipment:

JST connectors are used in industrial equipment such as machinery, robotics, and automation systems. They facilitate the connection of diverse components and modules, allowing for effortless maintenance and replacement procedures.

4. Healthcare sector:

JST connectors are utilized in medical devices like patient monitors, ultrasound machines, and surgical equipment. They ensure a reliable and secure connection for transmitting vital data and power in these sensitive applications.

5. Aerospace and aviation:

JST connectors are used in aerospace and aviation applications for connecting various electrical systems and components. They are engineered to endure and function reliably in extreme temperatures, withstand vibrations, and operate seamlessly in high altitudes.

6. LED lighting:

JST connectors are commonly used in LED lighting systems for connecting LED strips, modules, and power supplies. They enable easy installation, maintenance, and customization of lighting setups.

7. Power supply and battery applications:

JST connectors are used in power supply and battery applications, such as connecting batteries in portable devices, chargers, and power adapters. They offer a reliable and effective link for the transmission of electrical power.

8. Communication systems:

JST connectors are used in communication systems like routers, switches, and network equipment. They are employed to establish connections between different modules and components, guaranteeing dependable transmission of data.

9.Audio and video equipment:

JST connectors find application in audio and video devices such as speakers, headphones, microphones, and cameras. They offer a secure and stable connection for transmitting audio and video signals.

Renewable energy systems: JST connectors are utilized in renewable energy systems, including solar panels and wind turbines. They play a crucial role in ensuring reliable and efficient connections within these systems, facilitating the transmission of power generated from renewable sources. They are used for connecting solar panels, batteries, and inverters, enabling efficient power generation and distribution.

What are the JST connector types?

JST (Japan Solderless Terminal) links are extensively employed in electrical and electronic circumstances for cable-to-cable and cable-to-panel associations. JST connector sizes encompass a spectrum of intervals and arrangements to cater to diverse demands. Some primary classifications of JST connector variants, organized according to their practical applications, include:

JST Connector Types: Wire-To-Wire Connection

Some commonly encountered solderless terminal units within this classification encompass the subsequent alternatives:

SM (2.5mm Pitch)

The SM connector is a wire-to-wire connector type with a 2.5mm pitch that has gained popularity for electrical connections. Produced by Japan Solderless Terminal, it possesses the capability to manage a current of three amperes at 250V and has the capacity to accommodate eight wires with a gauge size ranging from 28-22 AWG. It features a secure locking mechanism with high force/contact pressure and allows toolless mounting on panels of different thicknesses. The JST SM connectors are commonly used in decorative RGB LED strip lights.

Key features of the SM connector include:

- 2.5mm pitch: The SM connector follows the standard 2.5mm pitch, suitable for various wire sizes and applications.

- High current and voltage rating: It can handle up to 250V voltage and three amperes of current, making it suitable for low-power electrical devices.

- Multiple wire capacity: The SM connector can accommodate eight wires ranging from 28-22 AWG, providing flexibility and options for wire connections.

- Secure locking mechanism: It incorporates a secure locking mechanism with high force/contact pressure to ensure a reliable and stable connection.

- Toolless mounting: The SM connector can be mounted on panels of different thicknesses without the need for additional tools, saving installation time and cost.

Due to its reliability and ease of use, the SM connector has found widespread use in various applications. Particularly, it is commonly employed in decorative RGB LED strip lights, allowing for quick and reliable wire-to-wire connections, and facilitating installation and maintenance for users.

RCY (2.5mm Pitch)

RCY is a compact connector with a 2.5mm pitch, designed for use in a wide range of signal and power supply circuits. This connector offers several advantages, including its small size and the presence of free spring terminals, which contribute to stable performance and easy insertion/removal.

Key features of the RCY connector include:

- Compact size: The RCY connector is designed with a compact form factor, making it suitable for applications where space is limited or where a smaller footprint is desired.

- 5mm pitch: The connector follows a 2.5mm pitch standard, providing compatibility with various wire sizes and allowing for the efficient transfer of signals and power.

- Free spring terminals: The RCY connector incorporates free spring terminals, which ensure secure connections and reliable electrical conductivity. These terminals also make it easy to insert and remove wires without the need for additional tools.

- Stable performance: The use of free spring terminals helps to maintain stable performance by minimizing the risk of loose connections or intermittent signals.

- Versatile application: Due to its compact size and versatility, the RCY connector is suitable for a wide range of applications, including electrical circuits that require both signal transmission and power supply.

The RCY connector offers a convenient and reliable solution for connecting wires in various signal and power supply circuits. Its compact size, free spring terminals, and stable performance make it a popular choice for applications where space is limited, such as in consumer electronics, industrial equipment, and automotive systems.

JST Connector Types: Wire-To-Board Connection

The standard wire-to-board JST connector that provides the most dependable linkage comprises the subsequent elements:

SR/SH (1mm Pitch)

The SR/SH connector is a 1mm pitch pin connector with a compact and low-profile design. It features wings on the sides of the receptacle, which facilitate easy disconnection without the need to hold onto the wires. The enclosure of the connector is designated as SH, whereas the male part is denoted by SR.

The SR header is shrouded and includes a locking feature that ensures a secure mating connection with the receptacle. One advantage of the SR header is that it does not have any holes that could interfere with vacuum gripping equipment, making it suitable for automated assembly processes.

The SH connectors are specified with a current rating of 1A and a voltage rating of 50V. They are compatible with 32-28 AWG wires, providing flexibility in wire size selection. Additionally, the SH connectors can be used with SZ and SR IDC series connectors, expanding their compatibility and versatility.

The key features of the SR/SH connector include:

- Compact and low-profile design: The connector’s compact size and low profile make it suitable for applications where space is limited.

- Wings for easy disconnection: The wings on the sides of the receptacle allow for convenient and hassle-free disconnection of wires.

- SR shrouded header with locking feature: The shrouded SR header ensures a secure connection with the receptacle, and the locking feature adds extra stability to the connection.

- Compatibility with vacuum gripping equipment: The absence of holes in the SR header prevents interference with vacuum gripping equipment during automated assembly processes.

- Current and voltage ratings: The SH connectors have a current rating of 1A and a voltage rating of 50V, making them suitable for low-power applications.

- Wire compatibility: The connectors can accommodate 32-28 AWG wires, providing flexibility in wire size selection.

- Compatibility with other connectors: The SH connectors are compatible with SZ and SR IDC series connectors, allowing for seamless integration with existing systems.

Overall, the SR/SH connector offers a reliable and convenient solution for applications requiring a 1mm pitch pin connector. Its compact design, easy disconnection, secure mating connection, and compatibility with various wire sizes make it suitable for a wide range of electrical and electronic devices, including but not limited to consumer electronics, telecommunications, and industrial equipment.

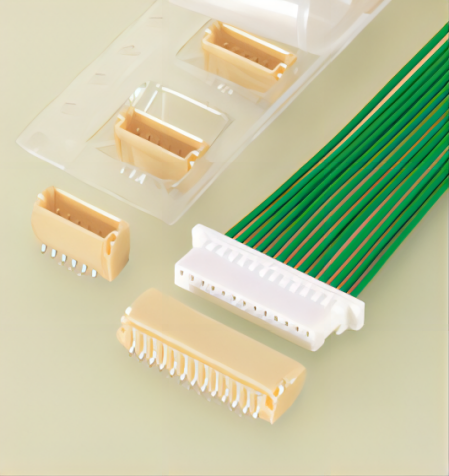

SHD (1mm Pitch)

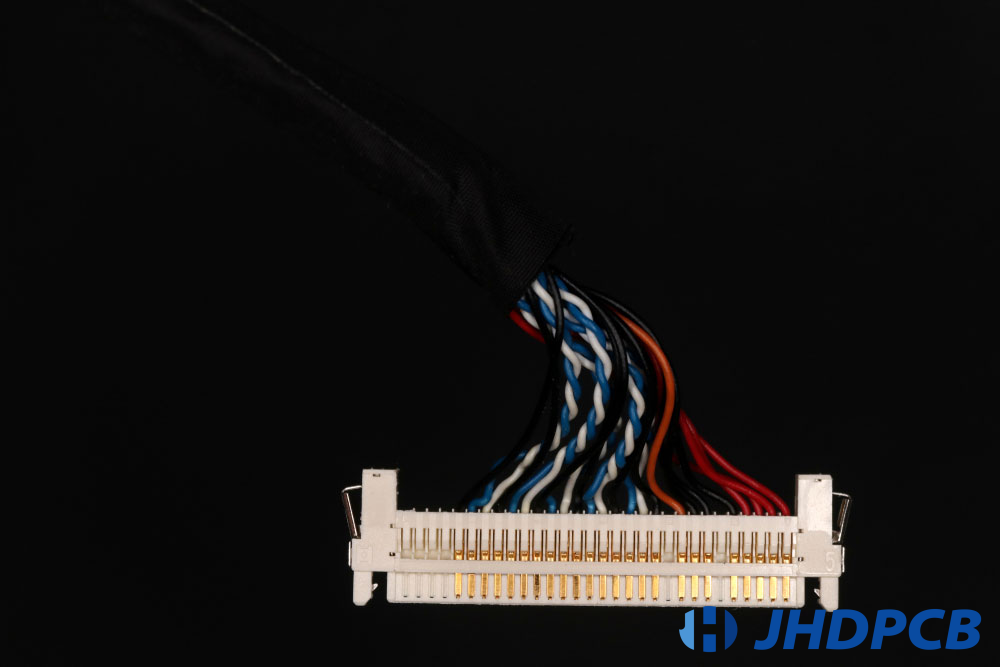

The SHD connectors, also known as JST SHD connectors, are larger versions of the SH type connectors mentioned earlier. They feature two rows of pins instead of a single row. These connectors are commonly used in LVDS (Low-Voltage Differential Signaling) and LCD (Liquid Crystal Display) applications.

The SHD connectors share many of the same attributes as the SH connectors but offer the advantage of a larger physical size. The larger size allows for more pins, enabling higher-pin-count connections, which are often required in LVDS and LCD applications.

Key features of the SHD connectors include:

- Larger size: The SHD connectors have a larger form factor compared to the SH connectors, accommodating two rows of pins.

- Two-row pin configuration: The connectors feature two rows of pins, providing a higher pin count for connecting LVDS and LCD circuits.

- LVDS and LCD applications: SHD connectors are commonly used in LVDS and LCD applications due to their ability to handle higher pin counts and support the requirements of these interfaces.

- Similar features to SH connectors: While larger in size, the SHD connectors retain many of the features of the SH connectors, such as a compact design, reliable connections, and compatibility with specific wire sizes.

- Compatible with other JST connectors: The SHD connectors are part of the JST connector family, ensuring compatibility with other JST connectors and promoting ease of integration into various systems.

The SHD connectors are well-suited for LVDS and LCD applications that necessitate a higher quantity of connections. They provide an ideal solution in such scenarios. Their larger size and two-row pin configuration enable efficient and reliable signal transmission in these applications. Additionally, their compatibility with other JST connectors ensures seamless integration into existing systems that utilize JST connectors.

GH (1.25mm Pitch)

GH connectors, with their 1.25mm pitch, offer a compact and precise interconnect solution for various applications. Below are some essential details regarding JST GH connectors:

- Pin-to-pin pitch: GH connectors have a pin-to-pin pitch of 1.25mm, making them suitable for applications that require a fine pitch connection. This narrow spacing allows for more connections in a limited space, enabling higher density and miniaturization of electronic devices.

- Low-insertion force: GH connectors are designed with a low-insertion force mechanism, ensuring easy and smooth insertion of pins into the connector housing. This characteristic minimizes the likelihood of causing harm to the connector or its components while establishing the connection.

- Positive latching mechanism: GH connectors feature a positive latching mechanism that securely locks the connector in place. This mechanism prevents accidental disconnection caused by external forces, vibrations, or movement, ensuring a reliable and stable connection.

- Similar to SHL connector contact section: The contact section of GH connectors is similar to that of the SHL connector. This means that GH connectors inherit the reliable and proven quality of the SHL connector, making them a trusted choice for interconnectivity.

- Secure locking mechanism: The secure locking mechanism in GH connectors enhances the stability and integrity of the connection. It guarantees that the connection maintains its stability even in challenging environments or applications that involve significant vibration levels.

- Current and wire compatibility: GH connectors can handle a current rating of up to 1A at 50V. They are compatible with 30-26 AWG wires, allowing flexibility in wire selection based on specific application requirements.

- Differentiation from Molex PicoBlade: Although GH connectors may share similarities with the Molex connector family, particularly the PicoBlade connector, they are distinct products. To ensure the appropriate selection for specific applications, it is crucial to distinguish between the two options.

In summary, GH connectors with their 1.25mm pitch, low-insertion force, positive latching mechanism, and secure locking mechanism provide a reliable and convenient interconnect solution. They are capable of handling various wire sizes and offer compatibility with the trusted SHL connector contact section. While some confusion may arise due to similarities with the Molex PicoBlade, it is crucial to distinguish between the two connector families for optimal application performance.

ZH (1.5mm Pitch)

ZH connectors are specifically designed for thru-hole wire-to-board connections and have a pitch of 1.5mm, making them one of the smallest pitch JST connectors available for this type of connection. While other smaller types of connectors are suitable for surface mount device (SMD) connectivity, ZH connectors excel in providing reliable and secure wire-to-board connections.

Key features of ZH connectors include:

- Dimple for positive terminal contact: TheJSTZH connector unit is equipped with a dimple in the middle, which ensures a positive terminal contact with low resistance. This design characteristic improves the overall performance and reliability of the connector, resulting in better functionality and dependability.

- Fully shrouded header: ZH connectors come with a fully shrouded header, providing additional protection and stability for the connection. The shrouded header helps prevent accidental disconnections, provides mechanical support, and minimizes the risk of short circuits.

- Compatibility with ZM (crimp) and ZR (IDC) series connectors: ZH connectors are designed to be compatible with other JST connector series, such as the ZM (crimp) and ZR (insulation displacement contact) series connectors. This compatibility facilitates seamless integration into existing wiring systems or enables the creation of multi-connector setups with ease. It simplifies the process of incorporating the connector into various configurations.

ZH connectors offer a compact and reliable solution for wire-to-board connections that require a pitch of 1.5mm. The inclusion of the dimple ensures a positive terminal contact with low resistance, enhancing the electrical performance of the connector. The fully shrouded header adds an extra layer of protection and stability to the connection.

Furthermore, the ZH connectors’ compatibility with the ZM (crimp) and ZR (IDC) series connectors expands their usability and versatility. This compatibility enables seamless integration into various wiring systems and facilitates the creation of complex or customized interconnect solutions.

Overall, ZH connectors provide a reliable and efficient solution for thru-hole wire-to-board connections with their tiny pitch, positive terminal contact design, fully shrouded header, and compatibility with other JST connector series. These attributes make them well-suited for a diverse range of applications where compactness, secure connections, and stability are essential requirements. They offer versatility and reliability in various scenarios.

PA (2mm Pitch)

JST PA connectors are popular for their 2mm pitch and high electrical capabilities. Here are some key points about PA connectors:

- High electrical capabilities: PA connectors are designed to handle a current rating of up to three amperes at 250V. This high current and voltage rating makes them suitable for applications that require robust electrical performance.

- Secure locking mechanism: To ensure a secure and reliable connection, PA connectors are equipped with a secure locking device. This mechanism prevents accidental disconnections caused by vibrations or pulling forces, providing a stable and uninterrupted power supply.

- Wire compatibility: PA connectors are compatible with 28-22 AWG wires, allowing flexibility in wire selection. This range covers a variety of wire sizes commonly used in electronic applications, enabling versatile and reliable connections.

- Popular battery connectors: Popular battery connectors, such as JST battery connectors, are particularly popular as battery connectors in RC FMA Cellpro battery chargers. These JST connectors provide a reliable and efficient method for connecting batteries to charging systems, ensuring safe and fast charging processes.

In summary, PA JST connectors with their 2mm pitch, high electrical capabilities, and secure locking mechanism offer a reliable and convenient interconnect solution. Their compatibility with a range of wire sizes makes them versatile in various applications. Specifically, they are widely used as battery connectors, including in popular RC FMA Cellpro battery chargers.

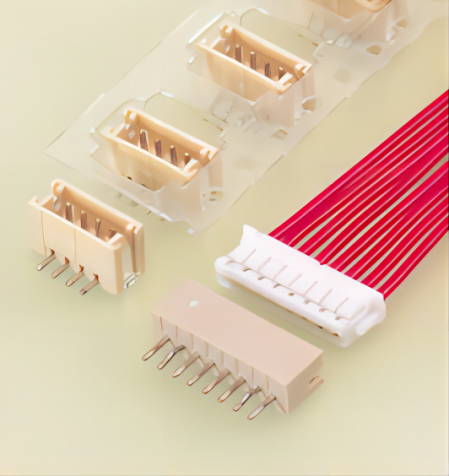

PH (2mm Pitch)

PH connectors are frequently employed for compact connections of internal cables to computer PCBs (printed circuit boards). Here are some key points about JST PH connectors:

- Power ratings: Unlike the PA connectors, PH connectors have lower power ratings, typically rated at 2A at 100V. While they may not handle as high of current and voltage levels as PA connectors, they are still suitable for many electronic applications that require moderate power requirements.

- Lack of secure locking devices: PH connectors generally do not have secure locking devices. This implies that they depend on the resistive force between the male and female connectors to uphold the linkage. Despite the absence of a secure locking mechanism, PH connectors can still provide reliable connections in applications where vibrations or pulling forces are not significant concerns.

- Dense connections: PH connectors demonstrate exceptional performance in situations that require high packing density and restricted space. Their compact size and 2mm pitch allow for efficient and tightly packed connections on computer circuit boards. They enable the routing of numerous internal wires within a small area, optimizing the use of available space.

- Compatibility with other connectors: PH connectors are compatible with other JST connectors such as the CR, KR, and KRD IDC series. This compatibility enables smooth integration with current systems or the potential to merge diverse connector types based on requirements.

- Typical usage in stepper motors: PH connectors find typical usage in stepper motors, which require precise control of position and speed. These connectors provide a reliable interface between the stepper motor and its driver circuitry, ensuring accurate and efficient motor operation.

- Affordability: One of the key selling points of PH connectors is their affordability. They provide a cost-efficient resolution for interconnectivity requirements while maintaining high performance and reliability.

In summary, PH connectors are characterized by their lower power ratings, lack of secure locking devices, suitability for high-density connections, compatibility with other JST connectors, typical usage in stepper motors, and affordability. While they may not handle as high power levels as PA connectors, they excel in applications that prioritize compactness and cost-effectiveness.

XA (2.5mm Pitch)

XA connectors are known for their 2.5mm pitch and their ability to handle similar power requirements as PA terminals. Here are some key points about XA connectors:

- Power requirements: XA connectors are designed to handle power requirements comparable to PA connectors. They can safely accommodate high currents and voltages, providing reliable electrical connections.

- Wire compatibility: XA connectors are compatible with 30-20 AWG wires, offering a broad range of wire size options. This flexibility allows for versatile applications and ensures compatibility with various wire gauges commonly used in electronic devices.

- Secure locking devices: XA connectors feature secure locking devices, which prevent accidental disconnections caused by vibrations or external forces. These locking mechanisms ensure a secure and stable connection, enhancing the reliability of the electrical connection.

- Glass-filled PA66 nylon: The header wafers of XA connectors are constructed using glass-filled PA66 nylon, which is a solder crack preventive material. This material helps to minimize the risk of solder cracks during manufacturing or usage, ensuring long-term durability.

- Circular, reflow-treated header pins: XA connectors are equipped with circular, reflow-treated header pins. These pins have a low insertion force, making it easier and more convenient to connect and disconnect the connectors. The reflow treatment ensures optimal soldering and enhances the overall reliability of the connections.

- Shrouded headers and polarizing bosses: XA connectors offer additional features such as shrouded headers on radial tape and headers with polarizing bosses. Shrouded headers provide added protection to the connector contacts, reducing the risk of damage or accidental short circuits. Polarizing bosses help ensure proper alignment and orientation during connection, preventing incorrect mating and potential damage to the connectors.

In conclusion, XA connectors with their 2.5mm pitch, similar power requirements to PA terminals, secure locking devices, solder crack preventive material, low insertion force header pins, and additional features like shrouded headers and polarizing bosses offer a reliable and versatile interconnect solution. They are appropriate for diverse applications that necessitate sturdy electrical connections and dependable mating.

XH (2.5mm Pitch)

XH connectors, with their 2.5mm spacing, are built upon the adaptable and trustworthy NH series connectors. Here are some noteworthy aspects regarding JST XH connectors:

- Size and pitch: XH connectors have a slightly larger size compared to PH connectors but still maintain a compact design. They feature a 2.5mm pitch, allowing for efficient and space-saving connections in electronic devices.

- Mounting height: XH connectors have a relatively low mounting height of 9.8mm. This low profile makes them suitable for applications where space is limited, enabling the connectors to be installed in tight spaces without causing interference or obstruction.

- Versatility: XH connectors are known for their versatility. They can be used in various low-cost consumer electronics, providing reliable electrical connections for different applications. These connectors are commonly found in devices such as audio equipment, power supplies, and home appliances.

- Cost-effectiveness: XH connectors offer a cost-effective solution for interconnectivity needs. Their cost-effectiveness makes them a favored option for manufacturers seeking to minimize production expenses while ensuring dependable electrical connections.

- Compatibility: XH connectors are typically compatible with standard 2.5mm pitch wire-to-board connections. This compatibility enables seamless integration into current designs or the utilization of standardized components across multiple products.

- Reliable performance: Despite their lower cost, XH connectors deliver reliable performance. They provide secure and stable connections between wires and circuit boards, ensuring proper signal transmission and electrical conductivity.

In summary, XH connectors with their 2.5mm pitch, compact design, low mounting height, versatility, cost-effectiveness, compatibility, and reliable performance are commonly used in low-cost consumer electronics. They offer a practical and economical solution for achieving reliable electrical connections in various applications.

EH (2.5mm Pitch)

EH connectors are a perfect choice for attaining compact wire-to-board connections with high density on computer boards. Here are some essential details about JST EH connectors:

- Compact wire-to-board connectivity: Much like PH terminals, EH connectors are engineered to enable condensed wire-to-board connections within computer circuit boards. They allow for efficient routing and organization of wires in compact spaces, enabling effective integration and reliable signal transmission within electronic devices.

- Shrouded header: EH connectors feature a shrouded header design. The shrouded header provides additional protection to the connector contacts, minimizing the risk of accidental contact damage or short circuits. This characteristic improves the overall robustness and dependability of the connectors.

- Lack of secure locking device: Unlike some other connector types, EH connectors do not incorporate a secure locking device. It is important to note that the absence of a locking mechanism means that additional care should be taken to prevent accidental disconnections caused by vibrations or external forces.

- Power handling capability: EH connectors are capable of handling power flows of up to 3A at 250V. This power handling capacity makes them suitable for applications that require adequate power transmission, ensuring stable and reliable operation of connected devices.

- Wire compatibility: EH connectors support wire sizes ranging from 32 AWG to 22 AWG. This wire compatibility allows for versatile application options and ensures compatibility with various wire gauges commonly used in computer boards and similar electronic devices.

In summary, EH connectors are well-suited for high-density wire-to-board connections within computer boards. They feature a shrouded header for added contact protection and can handle power flows of up to 3A at 250V. While lacking a secure locking device, EH connectors provide reliable electrical connections and are compatible with a range of wire sizes.

RE (2.54mm Pitch)

RE connectors are extensively utilized for the purpose of linking office automation equipment, encompassing computers and their accompanying devices. Presented below are a few significant aspects concerning RE connectors:

- Similar to male pin headers and female DuPont connectors: RE connectors have a similar design concept to male pin headers and female DuPont connectors. They provide an interface for establishing electrical connections between different components or devices within an office automation system.

- Non-shrouded design: RE connectors do not have a shrouded design, meaning that the connector contacts are exposed. Precautions should be exercised during the handling and installation process to avoid inadvertent contact damage or the occurrence of short circuits. The non-shrouded design also allows for easy visual inspection and maintenance of the connectors.

- Lack of a locking mechanism: RE connectors do not incorporate a locking mechanism. This means that the connectors may not have the same level of physical security as connectors with locking features. However, they still provide reliable electrical connections when properly mated.

- Double leaf-springs: RE connectors are equipped with double leaf-springs. These springs ensure secure and stable mating and unmating of the connectors. The double leaf-spring design enables the connectors to withstand repeated stress from mating and unmating cycles, enhancing their durability and longevity.

- Application in office automation equipment: RE connectors find extensive application in office automation equipment. They are commonly used to establish connections between computers, printers, scanners, monitors, and other peripheral devices. The versatility of RE connectors allows for efficient interconnection and communication between various office equipment components.

In summary, RE connectors are non-shrouded connectors that lack a locking mechanism. Nonetheless, they incorporate dual leaf-springs, guaranteeing dependable connections while enduring repeated mating and unmating strains. These connectors are ideal for connecting office automation equipment, facilitating seamless communication and integration within computer systems and peripheral devices.

VH (3.96mm Pitch)

VH terminals, also known as VH connectors, are commonly used in consumer electronics for power supply, signal transmission, and output circuits. Below are some essential details regarding JST VH connectors:

- High current-carrying capacity: VH connectors are designed to handle high current flows. They possess a maximum current-carrying capacity of 10A at 250V, rendering them appropriate for applications that necessitate the transmission of substantial power.

- Shrouded and non-shrouded varieties: VH connectors are available in both shrouded and non-shrouded varieties. The shrouded version features a protective housing that covers the connector contacts, providing additional safety and protection against accidental contact damage or short circuits. The non-shrouded version does not have this protective housing.

- Positive latching mechanism: Both shrouded and non-shrouded VH connectors incorporate a positive latching mechanism. This mechanism ensures secure and reliable mating of the connectors, reducing the risk of accidental disconnections caused by vibrations or external forces. The inclusion of a positive latching feature improves the overall stability and integrity of the electrical connections.

- Broad wire compatibility: VH connectors are compatible with a wide range of wire sizes. They can accommodate wires ranging from 22 AWG to 16 AWG. This broad wire compatibility allows for flexible application options and enables the handling of higher current flows without compromising performance or safety.

- Consumer electronics applications: VH connectors find extensive use in consumer electronics, where they are employed in various power supply, signal transmission, and output circuits. They can be found in devices such as televisions, audio systems, gaming consoles, and other electronic appliances that require efficient power distribution and reliable signal transmission.

In summary, VH connectors are widely used in consumer electronics for power supply, signal transmission, and output circuits. They have a high current-carrying capacity, offer shrouded and non-shrouded options with a positive latching mechanism, and are compatible with a range of wire sizes. VH connectors ensure reliable connections in consumer electronic devices, providing efficient power distribution and signal transmission capabilities.

The list does not conclude there. Additional JST connectors within the product range encompass the following:

- J-FAT:

J-FAT connectors are designed for high-power applications and feature a secure locking mechanism for reliable connections. - BMSC:

BMSC connectors are compact, low-profile connectors used for board-to-board or wire-to-board connections in electronic devices. - CPM:

CPM connectors are wire-to-board connectors with a crimping mechanism, commonly used in automotive and industrial applications. - FAH:

FAH connectors are wire-to-board connectors known for their high current-carrying capacity and robust construction, making them suitable for power transmission applications. - GEZ:

GEZ connectors are miniature connectors often used for signal and data transmission in compact electronic devices. - SJG:

SJG connectors are board-to-board connectors that provide a secure connection while allowing flexibility and vibration resistance. - PBD:

PBD connectors are wire-to-board connectors featuring a positive lock mechanism for secure connections in various electronic applications. - BNI:

BNI connectors are wire-to-board connectors commonly used in consumer electronics, offering a reliable and space-saving solution. - HYV:

HYV connectors are specialized connectors designed for high-speed data transmission, typically found in computer and communication applications. - And more

How to crimp jst connectors?

To crimp JST connectors, you will need the following tools and materials:

- JST connectors:

JST connectors come in various types such as JST-XH, JST-SM, JST-PH, etc. Each type has different pin spacing and specifications. Select the suitable connector based on your specific requirements. - Wire:

Trim your wire to the desired length using wire cutters or wire strippers.Ensure that the wire is long enough to reach your desired connection points but not so long that it becomes difficult to work with or creates unnecessary slack. - Crimping tool:

Use a crimping tool specifically designed for JST connectors. These tools have multiple slots for different wire sizes and crimping sections for both the insulation and conductor. - Wire cutter and stripper:

Utilize a wire cutter and stripper tool to eliminate a segment of insulation from the wire, unveiling the conductor. Ensure that you strip an adequate length of insulation as per the connector’s guidelines.

To properly crimp JST connectors, follow these detailed steps:

- Prepare the wire:

Utilize a wire stripper to carefully remove the insulation from the end of the wire, exposing the conductor. Take care not to damage the conductor while stripping. Strip an appropriate length of insulation based on the connector size and wire gauge. - Insert the wire into the connector:

Carefully place the stripped end of the wire into the designated slot of the JST connector. Verify that the conductor is fully inserted and establishes a secure connection with the connector. The conductor should reach the back of the crimping section without extending beyond it. - Crimp the connector:

Place the connector into the crimping tool, aligning it with the appropriate crimping section for the wire size. Apply sufficient pressure to crimp the connector securely onto the wire. Make sure the insulation crimp section is properly compressed, and the conductor crimp section is tightly secured around the wire. The crimping tool must uniformly apply pressure to compress the connector without inflicting harm to the wire. - Check the crimp:

After crimping, visually inspect the connector to ensure that the wire is securely attached and there are no visible signs of damage or loose connections. Give the wire a gentle tug to confirm its stability. The crimp should be tight and secure, with no movement or play between the wire and the connector. - Repeat for additional connectors:

If you have multiple connectors to crimp, repeat the process for each connector. Make sure to strip and insert the wire correctly into each connector, and crimp them securely.

Remember to refer to the specific instructions and guidelines provided by the manufacturer for the JST connectors you are using. It is important to use the correct crimping tool, choose the appropriate gauge connector, and apply the right amount of pressure to ensure a reliable and secure connection.

Commonly used connector terms.

A connector is an electromechanical contrivance utilized to connect two electrical components, typically involved in linking a JST cable to a system or one cable to another within an electrical circuit. Various kinds of connectors, such as JST connectors, exist, each capable of accomplishing this task. Having a good understanding of general terminology can greatly assist in selecting the appropriate JST connector style that suits your needs.

Prior to embarking on our conversation regarding frequently utilized connectors, let us delve into the vocabulary employed to depict these linkages.

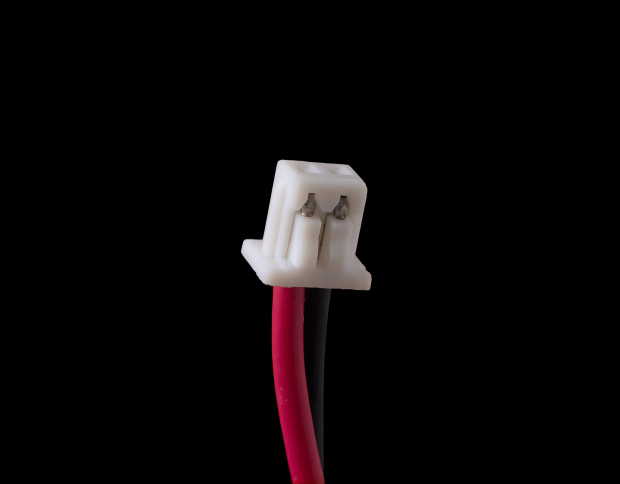

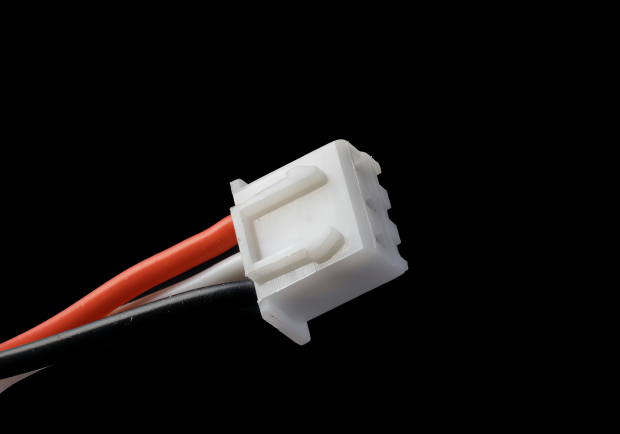

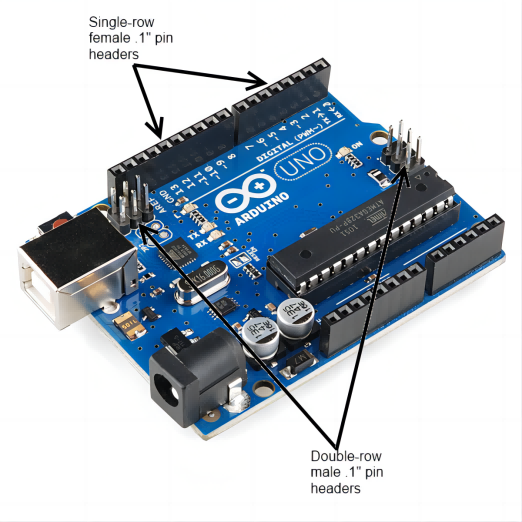

1.Gender

The term “gender” in the context of connectors defines whether it is categorized as male or female. A JST female connector typically has holes or sockets that are designed to accommodate the pins or plugs of a corresponding male connector. This distinction is important in electrical and electronic systems to ensure proper connection and compatibility between devices.

2.Polarity

The majority of connectors have a single specific orientation for proper connection. This attribute is known as polarity, and connectors that include features to prevent incorrect connections are described as polarized or keyed. These polarization or keying mechanisms ensure that connectors can only be mated in the correct alignment, avoiding potential damages or malfunctions.

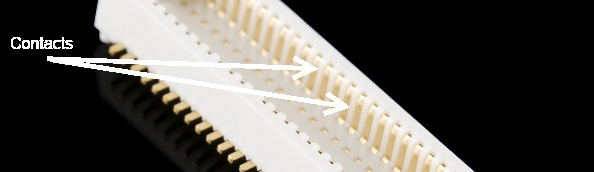

3.Contact

The interfaces within a connector consist of metallic elements that establish a physical connection, facilitating the transmission of electrical signals or power between interconnected devices. Nevertheless, complications can emerge concerning these interfaces as time progresses. The contacts may amass particulate matter, such as dirt, dust, or oxidation, impairing conductivity and causing intermittent connections. Likewise, the pliability and resilience necessary to ensure a steadfast contact may decline with time, potentially resulting in an unstable or undependable connection. Regular upkeep and cleansing of the contacts aid in alleviating these concerns.

4.Pitch

Numerous connectors are composed of a multitude of contacts arranged in a repetitive configuration. The connector’s pitch is defined as the gap between the central points of consecutive contacts. This factor holds significance as various contact families may exhibit striking resemblances but vary in pitch, thus posing challenges in ensuring the acquisition of the correct corresponding connector.

5.Mating Cycles

Connectors possess a limited lifespan, and their durability degrades with repeated connections and disconnections. This information is typically indicated in datasheets as “mating cycles,” and it varies significantly across different technologies. For instance, a USB connector may endure thousands or tens of thousands of cycles, whereas a board-to-board connector intended for consumer electronics may only last tens of cycles. It is crucial to choose a connector with an appropriate lifespan that aligns with the requirements of the specific application.

6.Mount

The term “mount” can be used to describe various aspects of a connector. It may pertain to how the connector is installed or positioned during use (e.g., panel mount, free-hanging, board mount), the angle at which the connector is oriented relative to its attachment (e.g., straight or right-angle), or the specific method of mechanical attachment (e.g., solder tab, surface mount, through hole). Further details and examples related to each specific connector will be discussed in the subsequent sections.

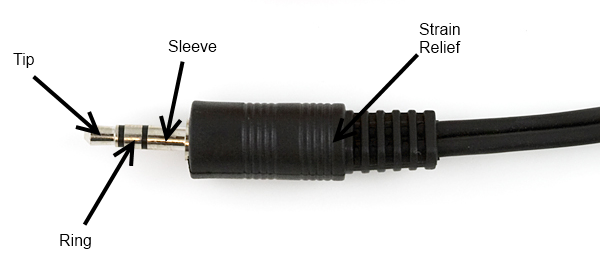

7.Strain Relief

When a connector is affixed to a board or cable, the electrical connections are frequently vulnerable to potential harm or damage.. To mitigate this, it is common practice to incorporate strain relief mechanisms that transfer any external forces exerted on the connector to a stronger mechanical structure instead of the delicate electrical connections. Detailed examples highlighting this concept will be provided later on.

These terms are frequently employed within the realm of diverse connector types, encompassing electrical, electronic, and telecommunications connectors. Familiarizing oneself with these terms facilitates the efficient selection, installation, and troubleshooting of connectors.

8.Male connector

A connector with exposed pins or prongs that fit into a corresponding female connector.

9.Female connector

A connector with holes or slots that receive the pins or prongs of a male connector.

10.Pin

A male contact that protrudes from a connector and makes contact with a corresponding female connector. JST connectors come in various pin configurations to accommodate different wiring needs:

- 2 pin JST connector: Similar to a JST connector 2 pin, a 2 pin JST connector is a type of JST connector with two pins. It is frequently utilized for basic two-wire connections, such as power and ground. The connector’s pins extend outward, enabling them to establish electrical contact with the corresponding female connector. This allows for a reliable and secure connection for transmitting power or signals between devices.

- JST connector 3 pin: With three pins, this JST connector provides additional flexibility for applications that require more complex wiring configurations. Each pin serves a specific purpose, such as power, ground, and signal transmission.

- JST connector 4 pin: Featuring four pins, this JST connector offers even greater versatility for applications that demand more connections. The pins ensure proper electrical connectivity between the male and female connectors.

- 5 pin JST connector: Likewise, a 5 pin JST connector consists of five pins and is well-suited for applications that necessitate a larger number of connections.

- 6 pin JST connector: Designed with six pins, this JST connector provides further flexibility for applications with more extensive wiring requirements.

In all cases, the pins of JST connectors extend from the connector housing, making physical contact with the corresponding female connector to establish an electrical connection.

11.Socket

A female contact that receives and makes contact with a male pin or prong.

12.Housing

The outer casing or body of a connector that holds and protects the contacts.

13.Mating:

Toggle Content

14.Unmating

The process of disconnecting two connected connectors.

15.Keying

The use of unique shapes or features on connectors to prevent incorrect connections or mismating.

16.Locking mechanism

A feature on some connectors that secures the connection and prevents accidental disconnection.

17.Termination

The method used to attach wires or cables to a connector, such as soldering, crimping, or screw terminals.

18.Shielding

The use of conductive materials or layers in connectors to protect against electromagnetic interference (EMI) or radio frequency interference (RFI).

19.Backshell

A protective covering or enclosure that is attached to the rear of a connector to provide strain relief and additional protection.

20.Insertion loss

The reduction in signal strength or power that occurs when a signal passes through a connector.

21.Return loss

The amount of reflected signal power at the connector interface, usually due to impedance mismatches.

22.Crosstalk

The unwanted transfer of signals between adjacent conductors or channels in a connector.

23.Environmental sealing

Environmental sealing refers to the capability of a connector to prevent the entry of moisture, dust, or other contaminants.

24.Durability

Durability refers to the capacity of a connector to endure multiple mating and unmating cycles without experiencing a decline in performance or reliability.

JST Connectors Q&A

What are the different types of JST connectors?

JST connectors come in various types, including JST-XH, JST-SH, JST-ZH, JST-PH, JST-SM, and many more. Each type has different pin configurations, sizes, and current ratings to suit different applications.

What are JST-XH connectors used for?

JST-XH connectors are commonly used for connecting lithium-ion battery packs, such as those found in laptops, drones, and RC vehicles. They provide a secure and balanced connection for charging and discharging the battery.

What is the difference between JST-SH and JST-ZH connectors?

JST-SH and JST-ZH connectors are both small, compact connectors used for signal transmission in electronic devices. The main difference is in the pitch (spacing between pins) and pin count. JST-SH connectors have a pitch of 1.0mm and a pin count ranging from 2 to 15, while JST-ZH connectors have a pitch of 1.5mm and a pin count ranging from 2 to 10.

Are JST connectors waterproof?

JST connectors are not inherently waterproof. However, there are some variants of JST connectors, such as JST-SM waterproof connectors, which are designed to provide a waterproof and dustproof connection. These connectors have additional seals and features to prevent water ingress.

Can JST connectors handle high currents?

The current capacity of JST connectors varies depending on the type and dimensions. Smaller JST connectors like JST-PH and JST-SH are typically rated for lower currents, while larger connectors like JST-XH can handle higher currents. It is important to check the datasheet or specifications of the specific JST connector being used to determine its maximum current rating.

Can JST connectors be crimped or soldered?

JST connectors can be crimped or soldered, depending on the type and application. Crimping is a common method for attaching wires to JST connectors, as it provides a secure and reliable connection. However, some JST connectors may also have solder tabs or pins, allowing for soldering if desired.

Where can I buy JST connectors?

JST connectors can be purchased from various electronic component suppliers, online retailers, and specialized connector distributors. Some popular sources include Digi-Key, Mouser Electronics, and Newark.

Are JST connectors compatible with other connector brands?

JST connectors have their own unique design and pin configurations, so they may not be directly compatible with connectors from other brands. However, there are adapters and conversion cables available that can facilitate compatibility between different connector types. It is crucial to review the datasheets and specifications of both connector variants to ascertain compatibility and the need for adapters.

Can JST connectors be used for high-temperature applications?

JST connectors come in different series and materials, some of which are designed for high-temperature applications. For example, the JST VH series offers high-temperature resistance up to 250°C. It is important to select the appropriate JST connector series and consult the datasheet or manufacturer for the maximum temperature rating to ensure compatibility with a specific high-temperature application.

Are JST connectors compatible with other connector types?

JST connectors are not generally compatible with other connector types, as they have their own unique design and pin configurations. However, there are adapter cables or harnesses available that can convert JST connectors to other connector types, allowing for compatibility with different systems.

Can JST connectors be used for high-speed data transmission?

JST connectors are primarily designed for power and low-speed signal transmission. They may not be suitable for high-speed data transmission applications, as they lack the shielding and impedance control required for such applications. In high-speed data transmission scenarios, other connector types like USB or HDMI connectors are typically used.

Are there any safety considerations when using JST connectors?

When using JST connectors, it is important to ensure proper polarity and correct mating of the connectors to avoid any short circuits or damage to the devices. It is also crucial to adhere to the specified current ratings of the connectors to prevent overheating or electrical failures. Additionally, using JST connectors in environments with high moisture or exposure to liquids may require the use of waterproof or sealed variants to maintain proper functionality and safety.

Are JST connectors standardized?

JST connectors are not part of a formal industry standard, but they are widely used and recognized in the electronics industry. JST is a brand name that has become widely recognized and synonymous with this particular type of connector. However, it is important to note that there are other manufacturers producing similar connectors, often referred to as “JST-style” connectors, which may have slight variations in design and specifications.

Can JST connectors be reused?

JST connectors are generally designed for single-use connections. However, if the connectors are handled carefully and not subjected to excessive stress or strain during disconnection, they can be reused a few times. Examining the connectors for any indications of harm or deterioration before reutilizing them is crucial to guarantee a dependable linkage.

Are there any alternatives to JST connectors?

While JST connectors are widely used, there are other connector types available that serve similar purposes. Some alternatives include Molex connectors, Hirose connectors, TE Connectivity connectors, and Amphenol connectors. The choice of connector depends on specific requirements such as size, current rating, pin configuration, and application.

To sum up, JST connectors are flexible and extensively employed in diverse electronic applications. They offer a reliable and compact solution for power and signal connections. Whether you need connectors for battery connections, power supplies, or signal transmission, JST connectors can meet your requirements. At JHDPCB, we understand the importance of quality connectors and seamless integration with PCBs. We offer a wide range of JST connectors and can assist in procuring them to be delivered along with your PCBs. Our team is dedicated to providing excellent service and ensuring customer satisfaction. Please feel free to contact us today to initiate a discussion about your connector requirements and how we can assist in fulfilling your project specifications.