FR4 Materials in PCB Manufacturing

jhdpcb@gmail.com

FR-4 and its characteristics make it widely used with a reasonable price. This is the main reason its using is so widely in PCB production. This article will comprehensively introduce the relevant knowledge and precautions of FR4 materials in PCB manufacturing:

directory

What is FR-4 laminate & FR-4 PCB?

FR4: FR4 is a standard defined by NEMA for glass reinforced epoxy laminates.

FR refer to “Flame Retardant” and means that the material with the UL94V-0 standard for the flammability of plastic materials. If the 94V-0 code available on all FR-4 PCBs. It ensures that the fire does not spread and goes out quickly when the material burns. And 4 distinguishes this material from other similar materials. FR4 material is a composite material structure. The most basic layer of the material is fiberglass, which is woven into a thin cloth surface.

FR-4 PCB: FR-4 print circuit board refers to the PCB processed with FR-4 copper base material. FR4 is the most common grade of dielectric material used to manufacture circuit boards. This material also common used in single-sided, double-sided, and multi-layer PCBs.

Learn more about JHD related FR4 PCB knowledge;

What are the properties of FR4 material?

1. Flame Retardant:

Chemicals used in materials to prevent or delay the spread of fire are called flame retardants. FR4 substrate has excellent thermal, mechanical and electrical properties, making it an ideal choice for various electronic applications. Flame retardant laminates and prepregs are widely used in various manufacturing processes and produce predictable results.

2. Good Electrical Performance:

The electrical characteristics of PCB material are very important for signal integrity and impedance consideration. They specify the speed at which the electrical signal travels through the material and how much charge can be retained in a given volume. The following table lists some important electrical characteristics and their typical values.

3. Hygroscopicity Is Good:

Hygroscopicity is the ability of PCB materials to resist water absorption when immersed in water. It is given by the increased percentage in the weight of the circuit board substrate due to water absorption under controlled conditions. The moisture absorption of FR4 material is as low as 0.10% after putting it in water for 24 hours.

| General Data From Normal FR4 | ||||

|---|---|---|---|---|

| Test Item | Treatment Condition | Unit | SPEC | Typical Value |

| Tg | DSC | °C | >110 | 135 |

| Flammability | C-48/23/50 E-24/125+des | / | 94V-0 | 94V-0 |

| Volume Resistivity | After moisture resistance E-24/125 | MΩ-cm | ≥10³ | 10^6 |

| Surface Resistivity | After moisture resistance E-24/125 | MΩ | ≥10³ | 10^6 |

| Arc Resistance | D-48/50+D-0.5/23 | S | ≥60 | 80 |

| Dielectric Breakdown | D-48/50+D-0.5/23 | KV | ≥40 | 55 |

| Dielectric Constant (1MHz) | C-24/23/50 | / | ≤5.4 | 4.5 |

| Dissipation Factor (1MHz) | C-24/23/50 | / | ≤0.035 | 0.021 |

| Thermal Stress/Unetched/Etched | 288°C ,solder dip | / | ≥10s No delamination | ≥10s No delamination |

| Peel Strength / Hoz | 288°C,10s 125°C | LBS/IN / | ≥6.0 ≥4.0 | 7.8 5.5 |

| Flexural Strength / LW / CW | A | MPa | ≥415 ≥345 | 550 435 |

| Moisture Absorption | D-24/23 | % | ≤0.35 | 0.20 |

| CTE TMA Z-axis / Before Tg / After Tg | TMA | 卩 m/m°c | / | 70 280 |

| CTI | IEC60112 Method | V | 175-250 (III) | 175 |

Classification of FR-4 CCL and Application of FR4 PCB

FR-4 Copper Clad Laminate Class A1:

This is mainly used in military, communications, computers, digital circuits, industrial instruments, automotive circuits and other electronic products. The quality of this series of products has fully reached the world-class level, the highest grade and the best performance.

FR-4 Copper Clad Laminate Class A2:

This is mainly used in general computers, instrumentation, advanced home appliances and general electronics. This series of copper clad laminates(CCL) is the most widely developed, and all performance indicators can meet the needs of general industrial electronic products.This can effectively improve the price competitiveness of customers.

FR-4 Copper Clad Laminate Class A3:

This grade of CCL is a FR-4 product specially developed and produced for the household appliance industry, computer peripheral products and general electronic products. Its characteristic is that the price is competitive on the premise that the performance meets the requirements.

FR-4 Copper Clad Laminate Class A4:

This grade is the low-end material of FR-4 copper clad laminate. However, various performance indicators can still meet the needs of ordinary household appliances, computers and general electronic products. Its cost is very cheap, price-performance ratio is also very good..

FR-4 Copper Clad Laminate Class B:

This grade of steel plate has poor quality and poor quality stability. Not fit for large-size PCBs. Its price is the cheapest, just pay attention to its selection and use.

Note that higher grades of FR-4 CCL are more expensive. We usually advise customers to select the appropriate material grade according to the actual PCB application needs. If you are not sure which material grade is the best for your project, you can send the relevant production information to JHD. Our professional engineers will check and give cost-effective suggestions. For other PCB CCL classification and quality standards, please refer to the article “What is CCL“;

FR-4 Material Types.

- Standard FR4: As the name suggests, it is standard FR-4 with heat resistance of about 140℃to 150℃.

- FR4 with high Tg: This type of FR-4 has a high glass transition temperature (TG) at 180℃.

- FR4 with high CTI: The relative tracking index is above 600 volts.

- FR4 without copper laminate: Suitable for insulating boards and board supports.

- FR4 G10: A glass fiber and resin laminated composite material, which has the characteristics of insulation, corrosion resistance and wear resistance. For specific G10 materials, please refer to “What Is G10 Epoxy Sheet?“

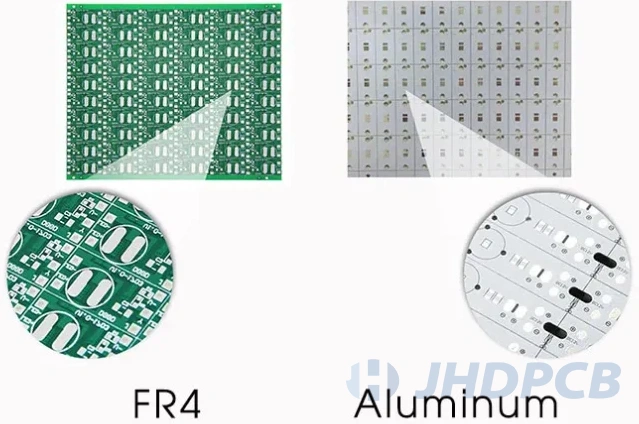

The Difference Between PCB Substrates: Aluminum and FR4

Aluminum:

LED aluminum substrate with good thermal conductivity, and then soldering electronic components on it. The important reason of using aluminum substrate is that it has great heat dissipation. Due to the large heating of high-power LED, most aluminum substrates are used for the production of LED lighting lamps. The quality of LED aluminum substrate according to the material model, hardness level, surface dealing and Alu plates thickness, and also selects the appropriate model and size with corresponding thermal conductivity.

FR4:

FR-4 glass fiber circuit board is a traditional circuit board of electronic products. It is widely used because of its good insulation, corrosion resistance, compression resistance, multi-layer printing and other characteristics. FR4 substrate,its glass transition (TG) is of the order of 115℃ to 200℃ for the High TGs or HiTGs depending on the manufacturing methods and the resins used. A standard FR-4 PCB will have a layer of FR-4 sandwiched between two thin copper layers. Learn more about high TG PCB;

FR-4 uses bromine, a fire-resistant so-called halogen chemical element. It replaces another less resistant composite G-10 in most applications.

The advantage of FR4 is that it has a good resistance. It does not absorb water, maintains high mechanical strength and has good insulation ability whatever in dry or humid environment.

Check other PCB copper clad laminate substrate characteristics;

FR4 Materials Advantages:

- Wide operating temperature range (50℃ to 115℃).

- Higher Tg value (about 180℃).

- Provides good mechanical properties to maintain board structure integrity.

- Compared with other materials, the cost is lower.

Limitations Of FR4 Circuit Board Materials:

FR4 has been used in the production of PCB for many years now. It’s low cost and provides adequate electrical insulation. However, the following problems may happened when FR4 is used in high-speed applications:

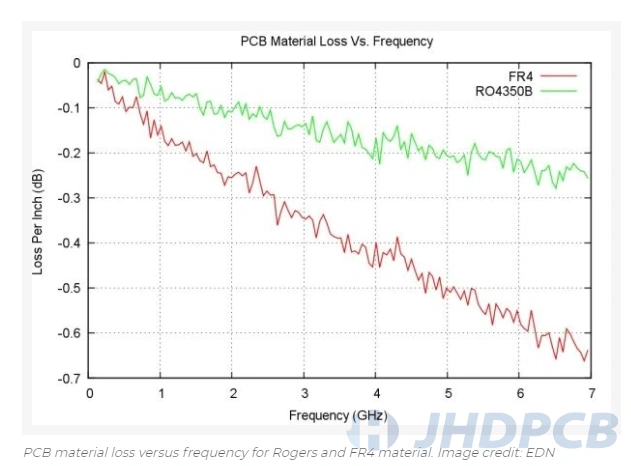

Controlled Impedance –

FR4 does not provide a uniform dielectric constant like high-speed board materials. Dk changes as the frequency increases. The dielectric constant tolerance of high-speed materials is less than 2%, while the dielectric constant tolerance of FR4 is as high as 10%. The Dk variation in FR4 presents challenges while maintaining impedance values. Therefore, this material is not the material of choice for controlled impedance boards.

Insulating Stability –

While FR4 is a good insulator, it also has its limitations under high power, high voltage, or high thermal conditions.The insulating performance of the material will deteriorate and it will begin to conduct electricity if fixed limits are exceeded. This can lead to plate failure.

Signal Losses –

Signal loss is an important factor to do PCB design, especially in high frequency applications. FR4 is not the best material for these applications because it has a larger Df (dissipation factor) than high frequency lamination.

The differences of FR4 CCL and FR-5 CCL.

GR-4 CCL: FR-4 is a code for the grade of flame-resistant material, which means that the resin material must be able to extinguish itself after combustion.

FR-4 epoxy glass cloth laminate is generally called FR-4 epoxy glass cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4, fiberglass board, fiberglass board, FR-4 reinforcing board, FPC reinforcing board, flexible circuit board reinforcing board, FR-4 epoxy resin board, flame retardant insulating board, FR-4 laminated board, epoxy board, FR-4 smooth board, FR-4 fiberglass board, epoxy glass cloth board Epoxy glass cloth laminate, drilling on circuit board plate.

FR5 CCL: FR5 epoxy plate is a plate-like laminated product made of special electronic cloth impregnated with epoxy phenolic resin and other materials by high temperature and high-pressure hot pressing. It has high mechanical and dielectric properties, good insulation, heat and moisture resistance, and good machinability Application: it is used as insulating structural parts in motors and electrical equipment, and is also widely used in PCB testing; It can be used in humid environment and transformer oil.

FR-5 has better advantages than FR-4:

A. TG and TD are higher;

B. The heat resistance is better, about twice as normal FR-4r;

C. Z-cte is not big and suitable for manufacturing multilayer PCBs.

Which PCB is not suitable for FR4 material?

As mentioned above, FR4 is really a good standard or default option in most cases. However, there are cases where FR4 is not the best material for a board, as shown below:

If high-frequency signal is used.

At high frequencies, FR4 boards cannot maintain constant impedance and reflections can occur, negatively affecting signal integrity. This is the result of a relatively high dk value. When high-frequency signals are required, we still recommend customizing high-frequency PCBs according to the requirements. Send your Gerber data if you are not sure if you need high-frequency material. Our professional engineers will check and give the best advice. Click to learn about high-frequency PCB knowledge.

If lead-free soldering is required.

If your boards will be sold in Europe and must comply with the Restriction of Hazardous Substances Directive (RoHS), or if your customers require lead-free soldering, then you may want to explore other material options. This is because the reflow temperature of lead-free PCBAs can be as high as 250°C, which greatly exceeds the Tg of many versions of FR4.

If the board is exposed to extremely high temperatures during operation.

It is also not wise to use FR4 if the PCB needs to work in an extremely high-temperature environment. For example, near the engine compartment of an aerospace vehicle.

Are you ready to have your pcb design manufactured? Try our quick quote tool to upload your CAD and BOM files in our website www.jhdpcb.com.

The PCB substrate plays a vital role in the performance of the board. JHDPCB as a top 5 and responsible PCB manufacturer in China. We will strictly control the quality of all types of substrates used in the PCB manufacturing process to ensure the smooth progress of downstream processes and use. We will advise you on the best selection based on your application conditions, PCB design and production process requirements. If you have any PCB related needs, please feel free to contact us, our professional customer service team will do our best to help you.

JHD’s Custom PCB Manufacturing Service.

- IPC-600, IPC-610 and ISO-9001,Quality Certification Commitment.

- Chat Support Available for 24 hours for Quick Turn.

- Get whole quotation online within one working day.

- Excellent procurement supply chain management

- The good cost performance help our client to improve price competitiveness.

- Lead time is as fast as 48 hours.

- Performs multiple automated inspections during assembly to ensure PCB quality for prototyping.

- Provides support throughout the PCB manufacturing process, beginning with Gerber file design.

- Fast transition from prototyping to bulk production.