The Ultimate Guide to UL 94V-0 Circuit Boards

jhdpcb@gmail.com

What does 94v-0 mean?

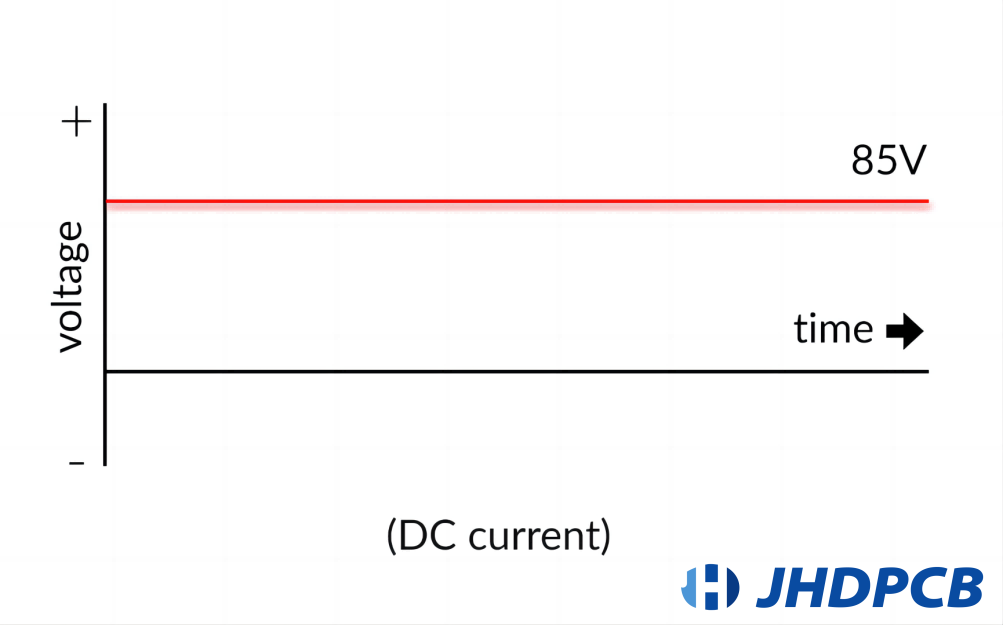

94V-0 is a rating given to materials used in the manufacturing of printed circuit boards (PCBs). It is a flame retardancy rating that indicates the material’s ability to resist catching fire and to self-extinguish if it does catch fire. The rating system was created by Underwriters Laboratories (UL), a safety consulting and certification company.

The “94” in the rating refers to the UL 94 standard, which is used to test the flammability of plastic materials. The “V” stands for vertical, and indicates that the test is conducted with the material in a vertical orientation. The “0” refers to the highest rating a material can receive under this standard, indicating that the material did not burn for more than 10 seconds after the source of ignition was removed.

Therefore, a 94v0 pcb board rating indicates that the material used in the PCB’s construction is highly resistant to catching fire and will not continue to burn after the ignition source is removed, making it a safer choice for electronic devices.

Material properties for UL94v.

UL94V is a flammability rating assigned by Underwriters Laboratories (UL) to plastics and other materials used in electrical and electronic equipment. The “V” in the rating stands for “Vertical”, which means that the material is tested in a vertical orientation.

There are different levels of the UL94V rating, ranging from V-0 (most flame retardant) to V-2 (least flame retardant). To achieve a V-0 rating, the material must meet the following requirements:

- The material must extinguish itself within 10 seconds of the removal of the ignition source.

- The material must not drip flaming particles that ignite cotton.

- The material must not have any glowing combustion after the flame source is removed.

- Standardized design: 94v0 circuit boards have standardized connector pins, making mounting and soldering electronic components easy.

- Assembly density: PCB design improvements include a multi-layer circuit board structure that overlays conductive copper linings and insulating materials. The result is a large circuit on a compact board.

In addition to meeting these requirements, materials with a UL94V rating must also have a number of other properties, including:

- High resistance to heat and fire.

- Low smoke emission.

- Good electrical insulation properties.

- Good mechanical strength and durability.

- Chemical resistance to common solvents and cleaning agents.

Overall, materials with a UL94V rating are designed to be safe and reliable for use in electrical and electronic equipment, where flammability and safety are critical factors.

What is a 94V-0 circuit board?

A 94V 0 circuit board is a printed circuit board (PCB) that has been manufactured using a plastic material that meets the flammability requirements of the UL94V-0 standard. This standard is set by Underwriters Laboratories (UL) and is used to test the flammability of plastic materials used in various applications, including circuit board manufacturing.

The “94V-0” rating indicates that the plastic material used in the circuit board has passed a vertical flame test, which measures the ability of the material to self-extinguish after being exposed to a flame. The test involves holding a flame to the bottom of a vertically oriented sample for a specific amount of time and then removing the flame to see if the material continues to burn or self-extinguishes within a certain period.

In the case of a 94v 0 board, the plastic material used in the board has been tested and found to meet the requirements of the UL94V-0 standard, which means it has a high level of flame retardancy and will self-extinguish quickly if exposed to a flame. This makes 94v-0 pcb circuit boards ideal for use in applications where fire safety is a concern, such as in consumer electronics, industrial controls, automotive, and aerospace applications.

It is important to note that the 94V-0 rating applies only to the plastic material used in the circuit board and not to the entire board itself. The performance of the circuit board as a whole will depend on factors such as the quality of the manufacturing process, the choice of components, and the design of the board.

What is UL 94V-0 flammability testing?

The UL 94 flammability test checks for flame resistance, but how is it done? First, the specimen (plastic) should be 127 x 12.7 mm (5 x 0.5 in.) of the minimum approved material thickness. The sample then gets exposed to a flame, and UL classifies the results into six categories.

- HB: This rating indicates a slow burn on the horizontal specimen. For a material measuring less than 3 mm in thickness, the burning rate should not exceed 76 mm per minute or stop before 100 mm.

- V-2: V stands for vertical, which indicates burning stops within 30 seconds when testing the specimen vertically. Also, the category allows burning drips from the flaming particles.

- V-1: V-1 is similar to V-2, but the difference is in the drips of particles, which should not get inflamed.

- V-0: With V-0, burning on a vertical specimen stops within 10 seconds, and the drops of burning particles should not get inflamed.

In the last two classifications, UL tests both bar and plaque specimens. Also, the flame source is roughly five times as severe as the one used in the upper four classifications.

- 5VB: Burning should stop within 60 seconds on both specimens when tested vertically. The plaque sample may develop a hole, but both should not form burning particles.

- 5VA: Burning stops within 60 seconds on the vertical samples, and the plaque may not develop a hole. There should be no drips as well.

What are the common 94v0 circuit board types?

Single-Sided PCBs:

There are many different types of printed circuit boards. Among them, single-sided printed circuit boards are very common; they are undeniably the most popular type of PCB. On the PCB there is a layer of copper that is individually conductive. Its distinguishing feature is that the electrical components are placed in precise positions on the PCB.

The entire etched circuit is visible at the other end. The conductors do not expand because of the conductive layer. This is consistent with the premise of low-density design. This single-sided substrate is found in low-cost devices. These include timing circuits, calculators, and lighting boards.

This type of PCB has several advantages for the user. It is not difficult to manufacture. Thus, it is very easy for manufacturers to produce. It also saves costs. It is not something that can be obtained at a high price. It is suitable for some designs where the density is not so high. If it breaks, it is very easy to repair. And finally, it is by no means difficult to design. That is because there is only a single layer of conductors.

Double-Sided PCBs:

This is a different type of PCB. Copper is added mainly to the top layer and also to the bottom layer of the PCB. This is on the sides. On each side, the metal parts can be connected through holes. Circuit technicians use this type of PCB for high-power devices such as amplifiers, UPS systems, phone systems, and some others. The advantage of this type is that it is more flexible than single-sided PCBs. It also provides a higher density of circuitry.

UL94V-0 is the flammability rating given to plastics, including those used in the manufacture of PCBs. It is not a standard for a specific type of printed circuit board, but for the flammability of the plastic materials used in printed circuit boards.

However, there are several common PCB types where UL94V-0 materials can be used. These include the following:

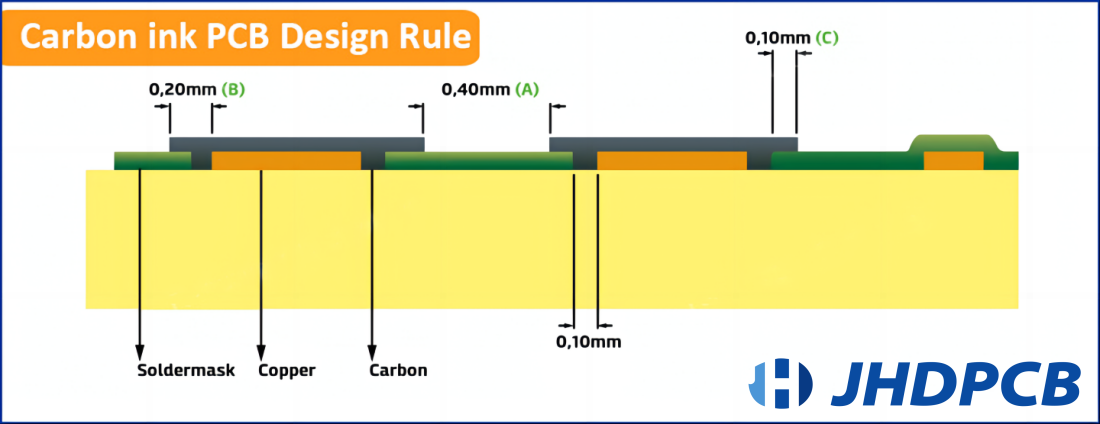

- FR-4: This is the most common type of circuit board material. FR-4 is a fiberglass-reinforced epoxy laminate that is highly durable, flame-resistant, and has good electrical properties. It is widely used in a variety of applications, including consumer electronics, industrial controls, and telecommunications equipment.

- Polyimide: Polyimide is a high-temperature plastic that is commonly used in applications where the board will be subjected to high temperatures, such as in aerospace and military applications. It is highly resistant to heat, chemicals, and radiation, and has excellent electrical properties.

- Rogers: Rogers is a brand of high-frequency laminates that are used in applications where signal integrity is critical. These laminates are made from a variety of materials, including ceramic-filled PTFE, woven fiberglass, and liquid crystal polymer, and are highly resistant to heat, moisture, and other environmental factors.

- Aluminum-based: Aluminum-based circuit boards are made by laminating a layer of aluminum onto a non-conductive substrate, such as FR-4. These boards have excellent heat dissipation properties and are commonly used in applications where thermal management is critical, such as in 94v0LED lighting and power electronics.

Overall, the choice of circuit board material will depend on the specific requirements of the application, including factors such as electrical performance, thermal management, and environmental resistance.

Why do I need a 94V-0 board?

This question arises for consumers, electronic and electrical equipment developers, and manufacturers alike.

- From the consumer point of view:

When buying an electrical appliance, it seems to make the most sense for most consumers to choose a cheap option. Choosing unbranded electronic devices, especially those that have no significant utility, such as light bulbs, doorbells, extension cords, etc., seems to be the most intuitive option because of their affordability.

However, if such an electrical device does not perform as promised or implied, consumers should opt for branded items that have a mark of authenticity.

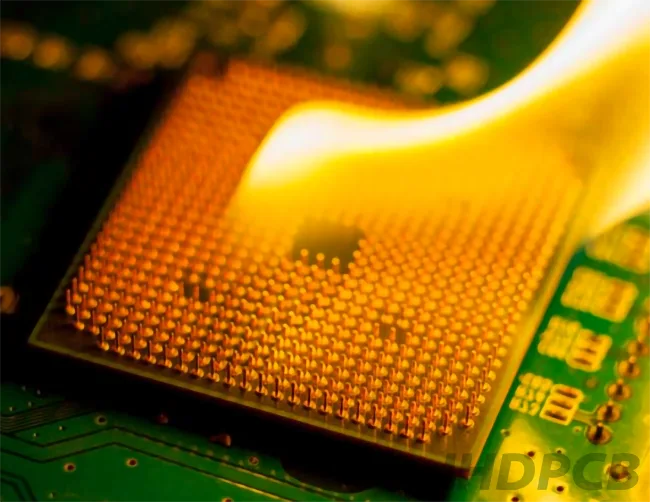

Some of these electronic devices can generate a lot of heat that is unbearable for the user. Consumers may also be alarmed by the extreme heat of electronic devices; they may fear fire or safety risks such as injury, etc.

In addition, electronic devices may deform due to the above-average heat, which affects their functionality and poses a risk to customers.

Based on this experience, customers usually buy these electronic devices only as temporary utility items or abandon them altogether. Such devices lose their sales value on the market. - From the perspective of an electronics developer:

Many electrical engineering students and many independent electronics developers must demonstrate their skills in projects that are evaluated to assess their academic performance or professional skills.

A prudent electrical engineering student should make sure that the project is optimized in all parts to get good grades. Similarly, an independent programmer should make sure that his electronic project meets and exceeds the standards in every aspect so that he can get a better position in a job or be selected in a prestigious company.

Selecting all components, including circuit boards, that must meet all standards can be the best way to ensure the project is accepted. Some universities or customers subject the electrical devices to an additional series of tests, such as thermal testing, to ensure the designs pass with flying colors. - From the manufacturer’s perspective:

Electronics manufacturers produce electrical and electronic devices that can be classified according to various criteria. Some of them focus heavily on the cost efficiency of their products, while others offer more features. Likewise, some electronics manufacturers add other criteria that raise the bar for their standards.

Designing electronics products for normal consumer use may not require special components and circuit boards; however, offering specialized devices that can withstand the rigors of the environment requires additional criteria such as ruggedness.

Many manufacturers have long used nanocoating technology for circuit boards, small electrical components and circuits, which makes the electrical device waterproof at the circuit level. The use of advanced 94V-0 circuit boards can make the devices heat resistant, which is equally destructive to the device in severe situations.

Using such options can allow the manufacturer to introduce more products, add another dimension to the product line and increase sales. In addition, such a high standard can increase brand value, credibility and market recognition.

Application areas of 94V-0 circuit boards.

94V-0 printed circuit boards add the utility aspect of heat resistance to electronic equipment. Electrical equipment manufacturers can use circuit board UL 94V-0 flammability testing to manufacture a wide variety of electronic devices and appliances.

94V 0 printed circuit boards are used in the following situations:

- Occupations requiring uncompromising durability.

94V-0 printed circuit boards are in great demand in occupations requiring heavy equipment, especially in combat-like situations, and in metalworking. They will not fail even after repeated or intermittent exposure to heat. - Occupations requiring uncompromising durability.

Certain occupations that rely on electronic equipment, the malfunction of which could result in death or serious consequences, require the use of PCB 94V-0. Hospitals, aviation equipment, and spacecraft require such durable PCBs. - Accident-prone occupations.

Accident-prone occupations require electronic and electrical equipment that is resistant to a variety of environmental conditions, including heat; UL 94V-0 certified PWBs will operate without problems in the event of an accident.

Large boilers, furnaces, mines, and metal processing plants. – These are occupations where accidents frequently occur. The electronic equipment used there must be able to withstand extreme heat so that it can continue to operate even in the event of an accident.

Thus, there are many areas and occupations that require the use of particularly rugged electrical equipment and devices. The use of 94V-0 printed circuit boards may be the best way to meet high temperature resistance standards. In recent years, many electronics manufacturers have introduced particularly rugged product lines. These rugged devices must be physically strong and resistant to water, heat, and electricity. For this reason, manufacturers are using 94V-0 printed circuit boards in their devices, making them more robust and attractive to the average consumer. - Consumer Electronics.

Consumer electronics, such as televisions, smartphones, laptops, and gaming consoles, require circuit boards that are safe and reliable. The use of 94V-0 rated materials in these devices helps to ensure that they do not pose a fire hazard to users. - Industrial Controls.

Circuit boards used in industrial controls, such as in manufacturing equipment, process control systems, and building automation systems, must be able to withstand harsh environmental conditions and have high reliability. 94V-0 rated circuit boards are commonly used in these applications to ensure that the systems are safe and reliable. - Automotive.

Circuit boards used in automotive applications, such as in engine management systems, entertainment systems, and safety systems, must be able to withstand high temperatures, vibration, and moisture. 94V-0 rated circuit boards are commonly used in these applications to ensure that they do not pose a fire hazard to passengers and do not compromise the safety of the vehicle. - Aerospace and Defense.

Circuit boards used in aerospace and defense applications, such as in avionics, communication systems, and weapon systems, must be able to withstand extreme temperatures, radiation, and other environmental factors. 94V-0 rated circuit boards are commonly used in these applications to ensure the safety and reliability of these critical systems.

Overall, 94V-0 rated circuit boards are used in a wide range of applications where fire safety is a critical concern, and where the reliability and performance of the circuit board are of utmost importance.

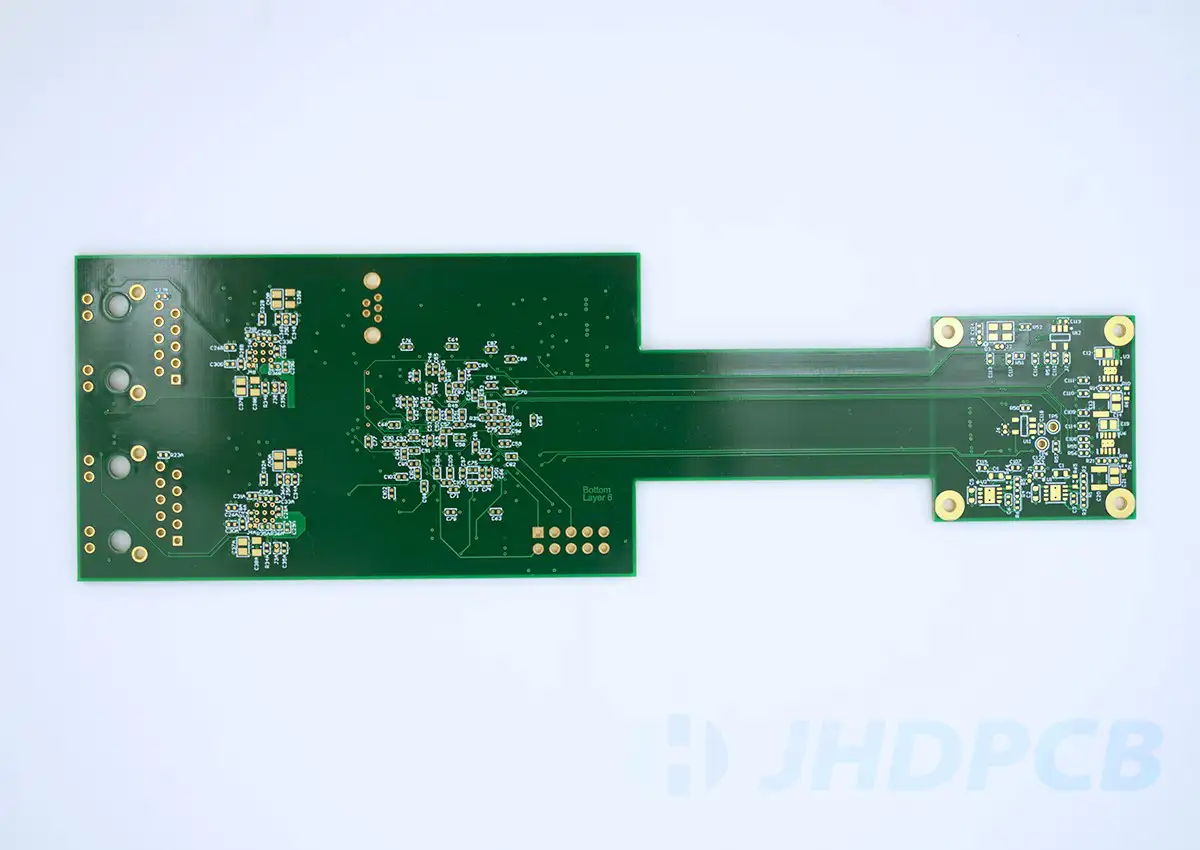

Choose JHD to customize your 94V board.

Many factors must be taken into account when designing PCBs. One of these is to ensure that the PCB complies with the approved UL flammability classification. For example, if you have to design a PCB for 94 V-0, it means that the sample will not burn for more than 10 seconds. If you are working with circuits, you need to choose the right materials to ensure that the PCB actually has a 94 V-0 rating. So, choosing a nice manufacture to customize your 94V board is very important. JHD is a good choice for you to satisfy for your all demands. Here are the reasons for you.

- Compliance with safety standards: JHD comply with safety standards for 94v boards. These boards are designed to meet the safety requirements for use in consumer electronics and other applications.

- High-quality materials: use high-quality materials in the manufacturing process. This ensures that the boards are reliable, durable, and can withstand the harsh conditions of various applications.

- Advanced technology and equipment: We have advanced technology and equipment to produce high-quality 94v boards. This includes computer-aided design (CAD) software, automated testing equipment, and high-speed manufacturing machines.

- Experienced team: We have a team of experienced engineers, designers, and technicians who can handle complex manufacturing processes and troubleshoot any issues that arise during production.

- Timely delivery: JHD are able to deliver the boards on time, without compromising on quality. This is crucial for meeting deadlines and keeping projects on track.

- Customization: We are able to offer customization options to meet the unique requirements of different applications. This includes customization of board sizes, shapes, and features, as well as special coatings or finishes to protect against moisture or other environmental factors.

- Competitive pricing: We can offer competitive pricing without compromising on quality. This ensures that customers get the best value for their money and can stay within their budget.