The effect of hole, character and outline design on PCB production

jhdpcb@gmail.com

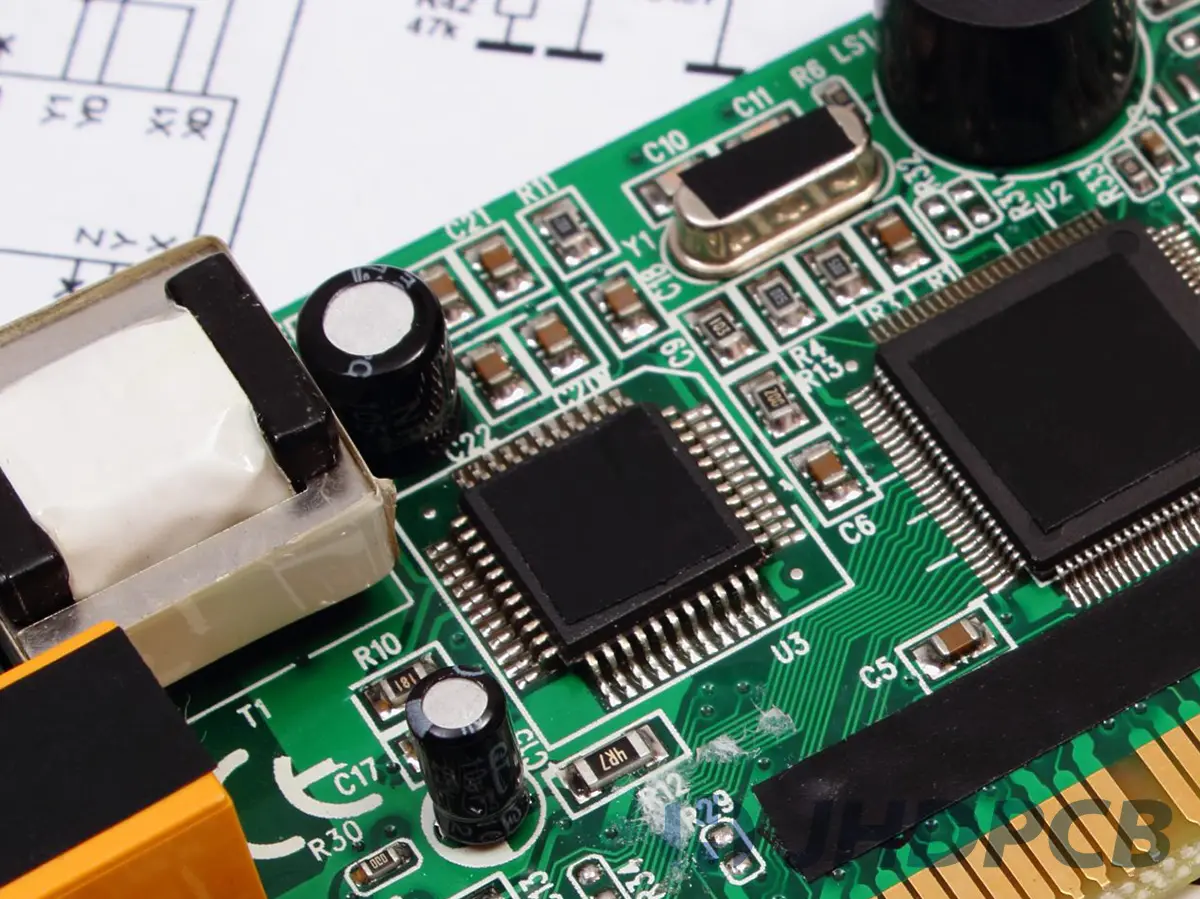

The PCB design is complicated, and various unexpected factors will affect the achievement of the overall pcb solution. To produce high-quality PCB boards on time, without increasing design time or incurring costly rework. Design and circuit integrity issues must be identified early in the pcb design process.

However, there are many details in the PCB design process. If some details are not paid attention to, they may greatly affect the performance of the PCB, and even determine the success or failure of the entire product.

In the actual process of docking with customers, JHDPCB has summarized some precautions for vias, character, shape and panel design.

We are well aware that in the main PCB production chain, although the cost of PCB design, development and design engineering does not account for a high proportion, it will have a great impact on the total cost.

In view of the important role of the PCB design stage on the quality and cost of the PCB, the following will combine the actual cases of vias, character, shape, and panel design to share expert solutions for some problems in the pcb design, so as to help reduce pcb production costs and increase efficiency in the whole process.

directory

How Via Designs Affects PCB Production?

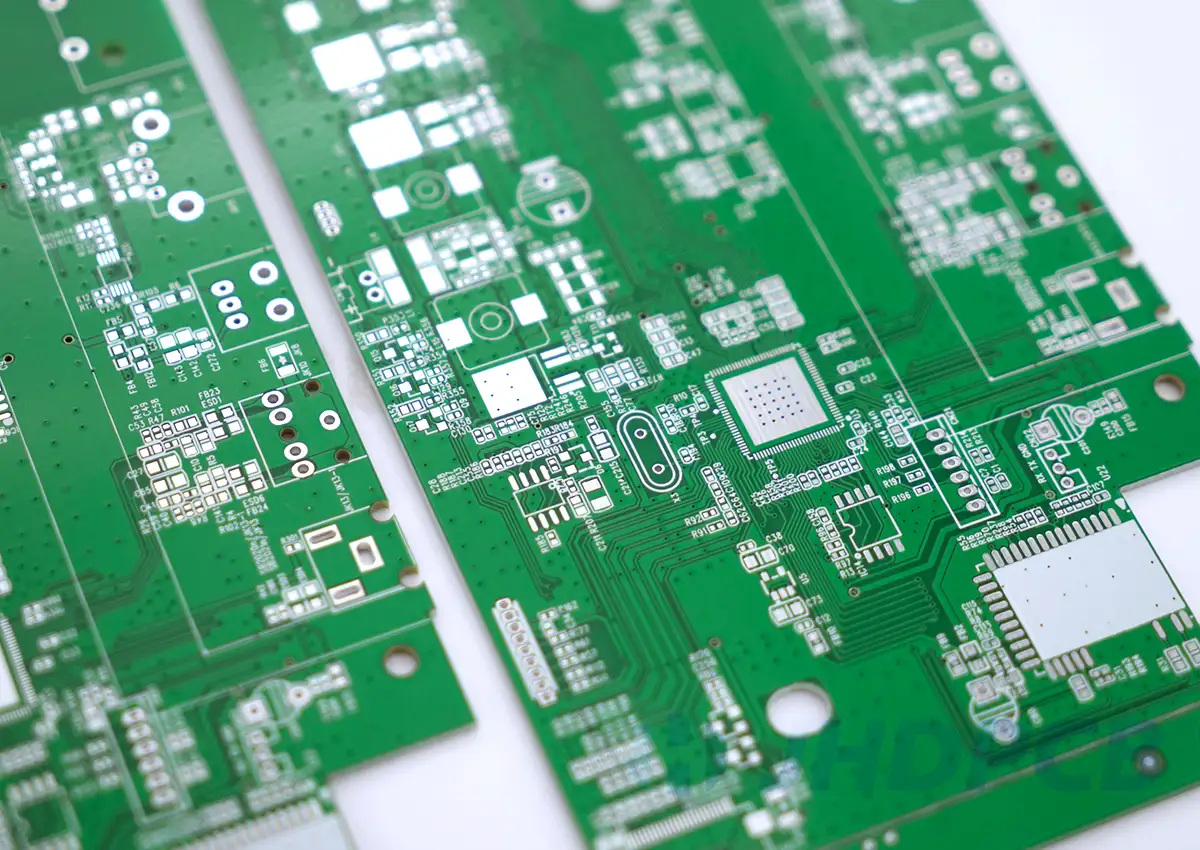

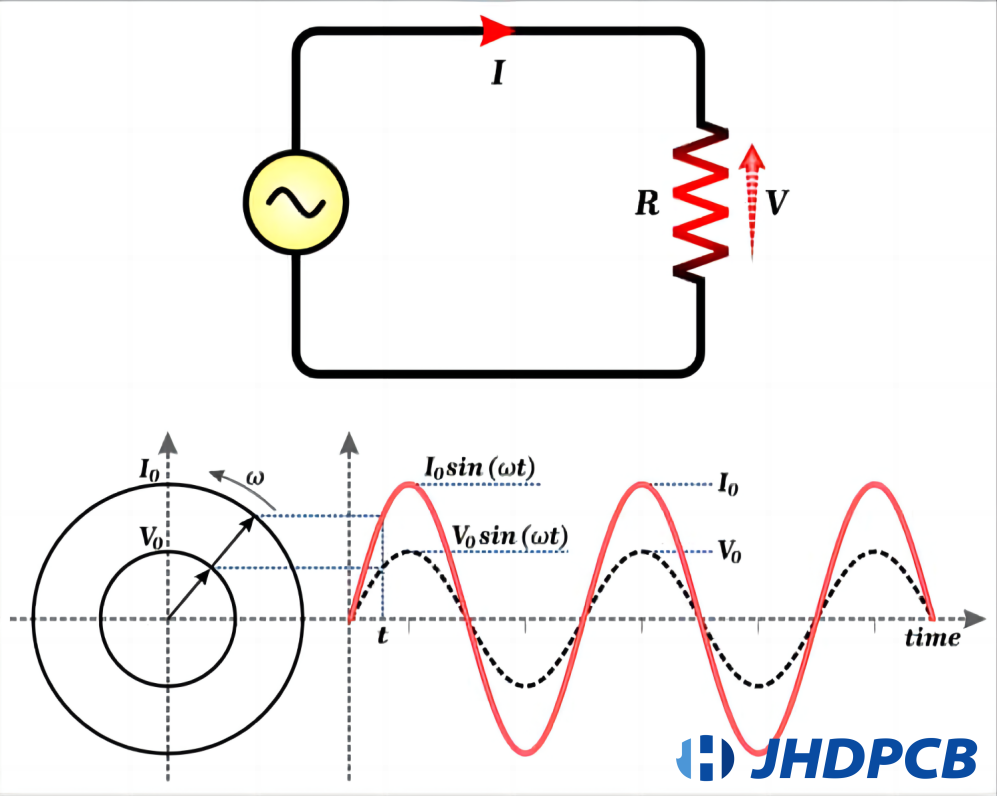

Through the vias to achieve inter-layer conduction, and gradually developed double-sided pcb and multi-layer pcb, HDI pcb, therefore vias have become a key point in PCB design. From a design point of view, vias are usually used to achieve two functions: electrical connection, support or positioning, one is to meet electrical characteristics, and the other is to achieve physical requirements.

The vias are sometimes classified into: vias, support holes, and the support holes are divided into device welding holes (this type of holes are basically metallized holes) and device mounting holes (this type of holes) Most of the holes are not metallized). For detailed PCB hole type information, please refer to our related blog.

The following JHDPCB combines some practical cases to share solutions for some problems in PCB via design.

01 Via design case 1: hole (PTH/NPTH) design and line connection need to follow the routine:

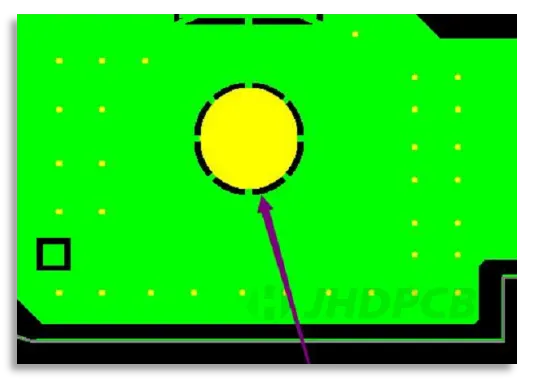

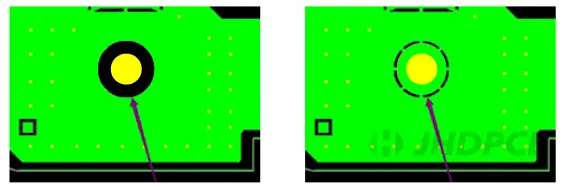

Problems:

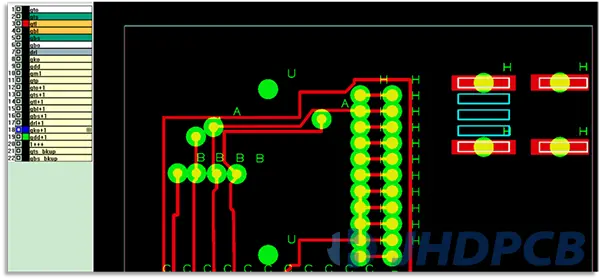

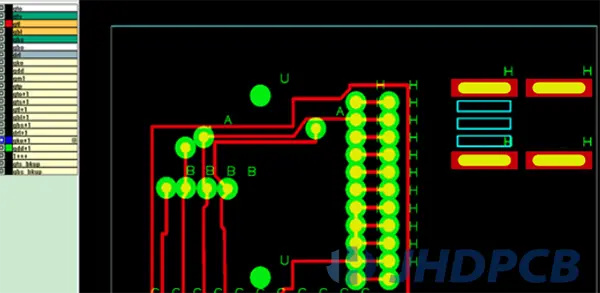

a. As shown in the figure above, the lines corresponding to the vias plate have electrical performance connections, and NPTH are required.

b. As shown in the figure above, the hole plate corresponds to the circuit without electrical performance connection, and requires metal holes.

JHDPCB Suggestion:

According to the standard design, if a non-metal hole is to be made, make sure that the corresponding circuit has no electrical performance connection, and the plate is the same size as the hole design or has no plate; if a metal hole is to be made, ensure that there is an electrical performance connection, or the plate is larger than the hole on one side about 5mil;

In addition, note that if metal holes are to be made but there is no disk in the corresponding circuit position, the back end must go through the positive electroplating process, and the delivery time will be extended by more than one day compared to the negative process, so this design is not recommended.

Correct design:

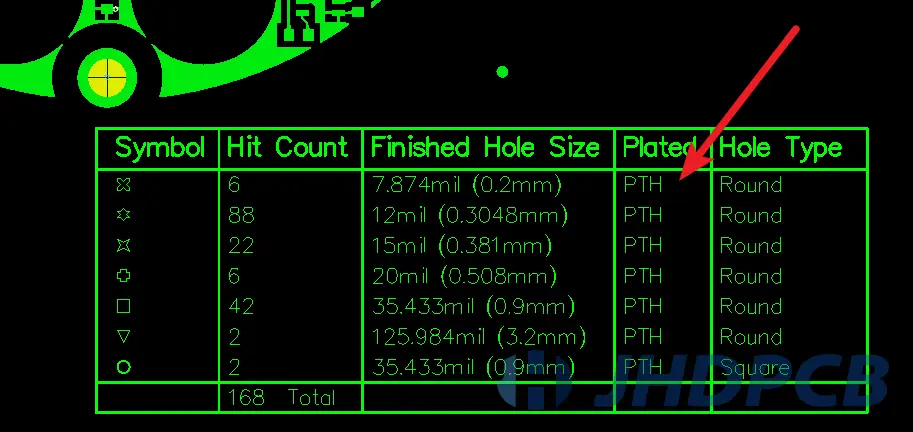

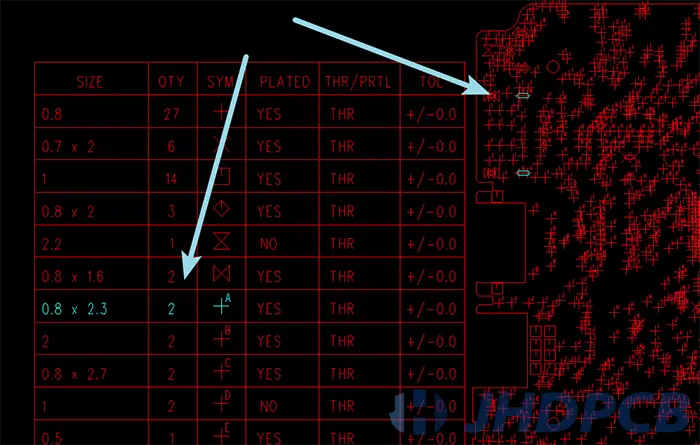

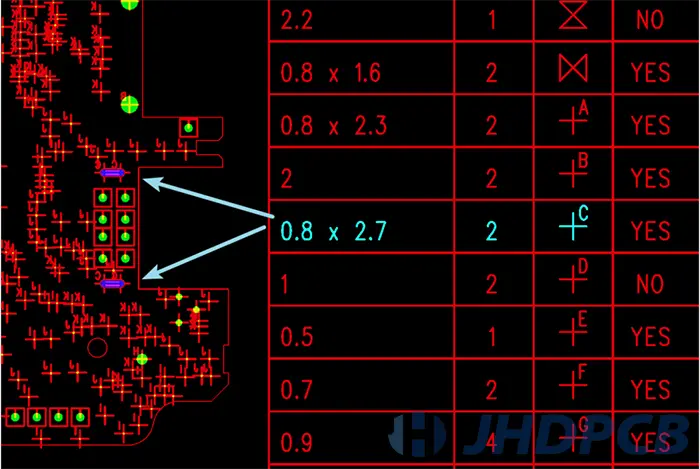

It is best to attach a hole table to clearly mark which are PTH and which are NPTH; it will lead to unnecessary time-consuming EQ communication.

For example:

02 Hole Design Case 2: Slot (metal/non-metal) layer design is differentiated and normalized:

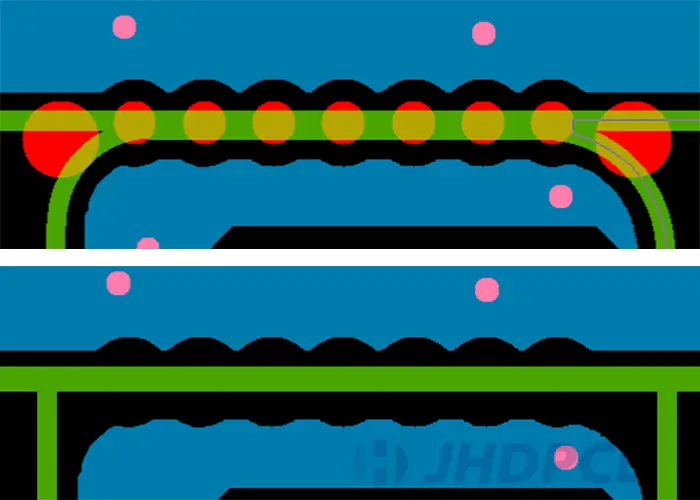

Problems:

There are 7 slots in the above picture. The customer requires that the three red positions in the middle should be made of non-metal slots, and the other four slots should be made of metal slots, but all slots are uniformly designed on the gdd layer. If according to the design, the normal default is to make non-metallic grooves, and the rear end will open the disk to prevent copper exposure during groove milling.

JHDPCB Suggestion:

Separate design, the non-metal slot is placed on the gdd or gm1 layer, the metal slot is placed on the drl layer, or the slot layer is output separately.

correct design:

03 Hole Design Case 3: Standardize the hole symbol, don't "hide" the slot:

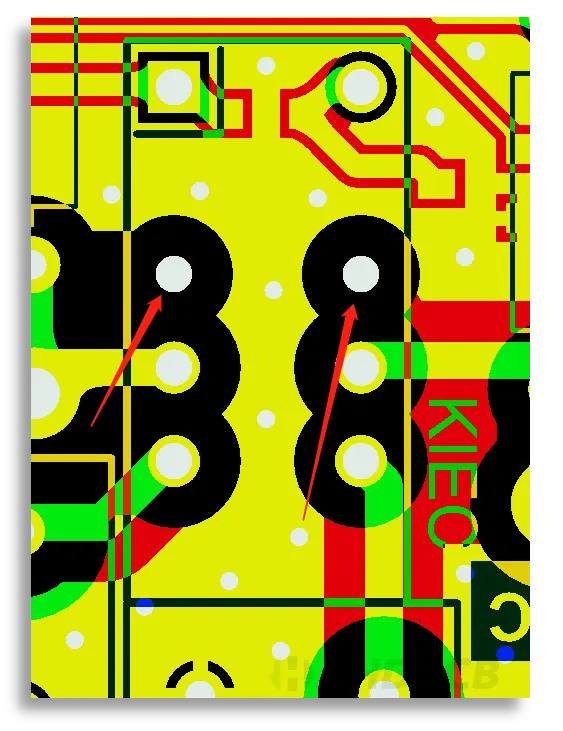

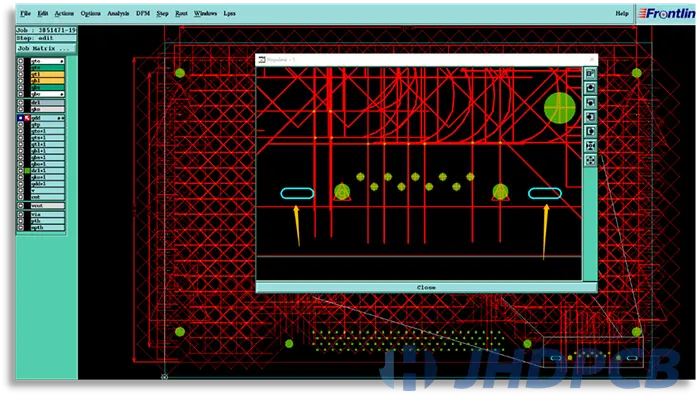

Problems:

1. The hole symbol mark in the pcb design file is too large. When the pcb manufacturers want to check whether the hole and the hole symbol correspond one by one, there is no way to start, therefore the hole position and size deviation caused by the import scale problem cannot be found;

2. The slot is designed in the corner of the hole symbol, and there is not any mark in the hole table, very easy to miss the slot.

JHDPCB Suggestion:

Do not design the hole symbol too big, and it can be clearly seen one by one corresponding to the drilling;

Provide a hole table, mark the position and parameters of the slot, or put it into the through-hole drl layer;

Correct design:

04 Hole Design Case 4: Standardize the hole symbol, don't "hide" the slot:

Problems:

The actual position of the hole design has a slot, the design is unreasonable and there is no additional explanation.

JHDPCB Suggestion:

Do not design holes and slots at the same position; provide a hole table, mark the position and parameters of the slot, and design the corresponding slot directly on the drl layer;

Correct design:

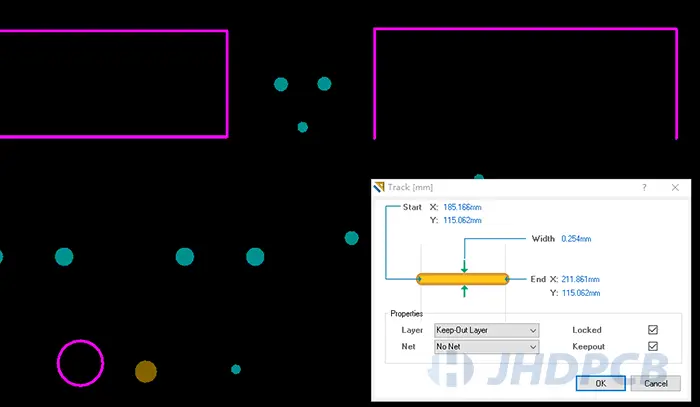

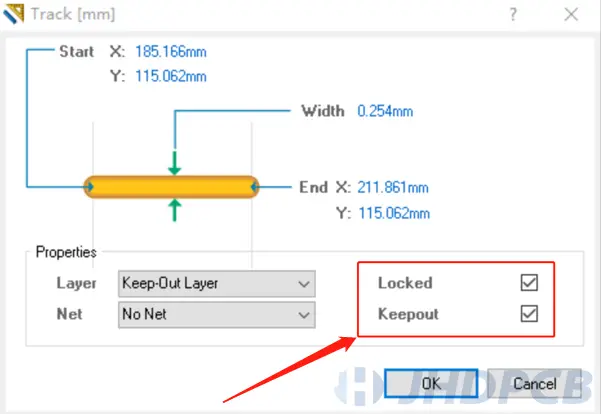

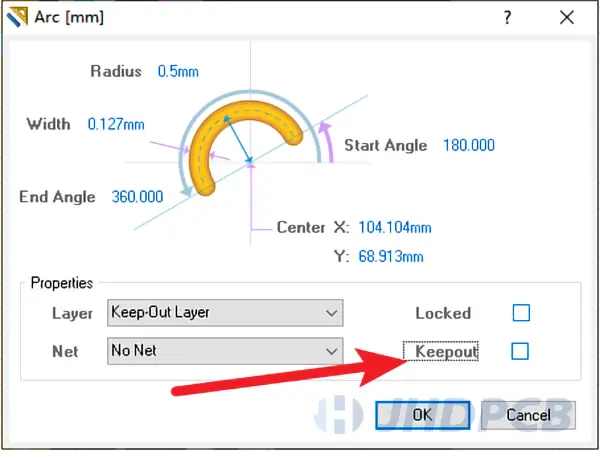

05 Hole Design Case 5: Do not "lock up" the slot when designing the PCB file:

Problems:

When converting PCB files to geber files, slot locking is easy to miss.

JHDPCB Suggestion:

When designing the PCB files, uncheck the Keepout- tagging option.

Correct design:

06 Hole design case 6: Solder mask ink plug hole via hole tolerance should not exceed 0.2mm:

Problems:

The solder mask plug hole is extremely poor, the large hole plug hole is not full, while the small hole ink plug hole is too much.

JHDPCB Suggestion:

When designing via plug holes, the plug hole range should not exceed 0.2mm.

Correct design:

Via(max)-Via(min) requirements≤0.2mm.

For detailed knowledge of PCB via coverage, please refer to our related pages.

How the Character Design Affects PCB Production?

Although character design defects do not affect the function and quality of the PCB, in order to mark the PCB information more clearly, and to avoid engineering problems caused by character design defects before production, please standardize the design of PCB characters.

Standardization of Character Design:

Problem:

The solder pad is usually mounted by machine, so seems the position of the character is not very important, but from the perspective of the JHDPCB manufacturer, if the character position on the pad, we will judge that the design is abnormal, and will communicate with the customer to change the position of characters or delete characters, which consumes valuable time.

JHDPCB suggestion:

For the convenience of maintenance and welding, the character symbols should be placed outside the frame during design, and the character symbols should be placed in order or not placed in the dense area.

Click for comprehensive PCB character silkscreen information.

How the Outline design Affects PCB Production?

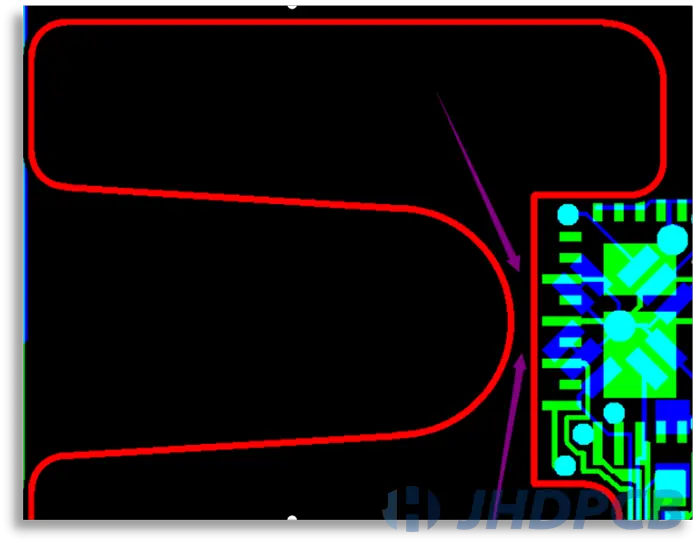

PCB Outline design case 1

Consideration when designing internal milling grooves.

The actual milling cutter can’t go in and the production efficiency problem. Check out our Mechanics article for detailed PCB milling knowledge.

Problem:

In the gerbers provided by the customer, the inner groove needs to be hollowed out, but the distance between the arches is less than 0.8mm, and the conventional milling cutter cannot enter.

JHDPCB suggestion:

If the function of this board is not affected, customers can be advised to increase the distance at the arc; place a “corner hole” at the concave corner (see the white arrow in the figure)

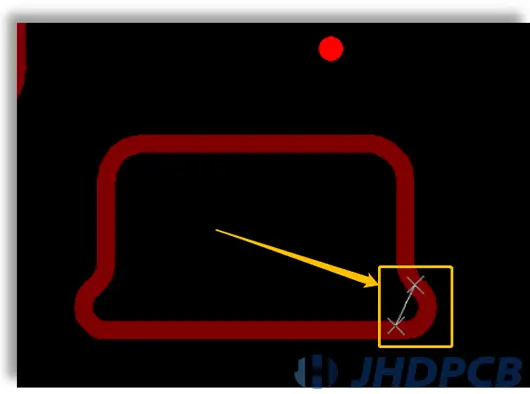

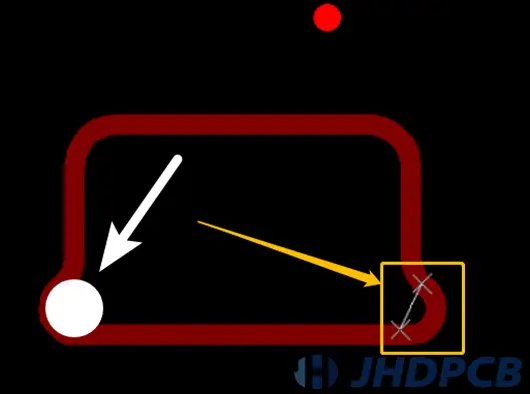

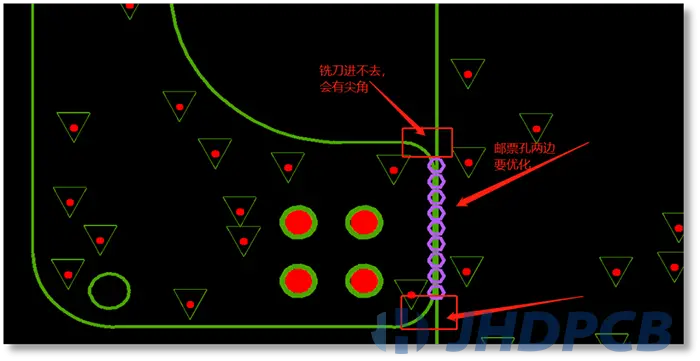

PCB Outline design case 2

Problem:

When the board edge connection position is designed, two adjacent boards have rounded corners on one side, straight edges on the other, and stamp holes in the middle. When the milling cutter cuts, there will be sharp corners behind the board, which needs to be welded.

JHDPCB suggestion:

without affecting the structure, it is recommended to change the rounded corners to right angles or add “corner holes” to increase production efficiency and make the boards more beautiful.

The above is a case of how to avoid the unreasonable design of PCB, resulting in delay in production time. JHDPCB sorts out these cases in daily communication with customers, can communicate with customers efficiently, and provide customers with fast delivery and high-quality PCBs. If you have other PCB manufacturing questions, please feel free to contact us, JHD will help you with professional knowledge and rich experience.