High frequency PCB

What is High Frequency PCB?

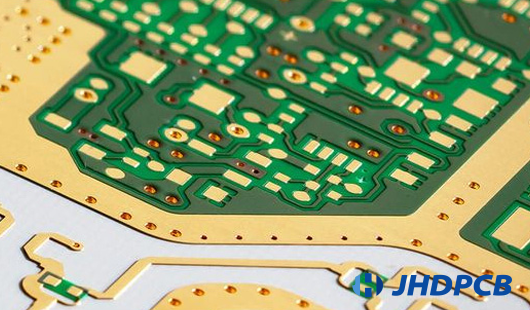

Electronic devices with high frequency are the developing tendency nowadays, especially in the wireless networks. Satellite communication growing rapidly, information products move towards high speed and high frequency. Thus developing new products always need to use high frequency substrate, satellite system, mobile telephone receiving base station and so on, these communication products must use high frequency PCB.

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radiofrequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

Features Of High Frequency PCB

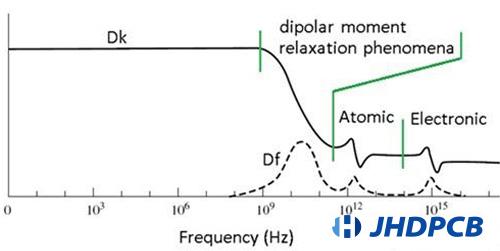

- DK should be small and stable enough, usually the smaller the better, high DK may lead to signal transmission delay.

- DF should be small, which mainly affect the quality of signal transmission, the smaller DF could make smaller signal wastage accordingly.

- The thermal expansivity should be the same with copper foil as much as possible because the difference will lead to copper foil separated in the changes of cold and heat.

- Water absorptivity must be low, high water absorptivity will affect DK and DF when in a wet environment.

- Heat-resisting property, chemistry resisting, impact endurance, peel off resisting must be good.

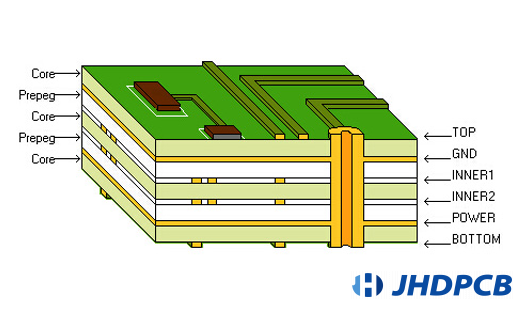

Multi-layered design:

We usually use multi-layered PCBs in high-frequency PCB designs. Multi-layered PCBs have assembly density and small volume, making them very suitable for impact packages. And multi-layered boards are convenient to shorten the connections between electronic components and improve the speed of signal transmission.

Ground plane designing is an important part of high-frequency applications because it not only maintains signal quality but also helps reduce EMI radiations.

How to choose the right material for high frequency PCB?

High-frequency boards for wireless applications and data rates in the upper GHz range have special requirements for the materials used:

- Substrates with low water absorption are more suitable for high-frequency PCB manufacturing, because it can better adapt to the influence of dielectric constant (DK) and dielectric loss (Df).Large ingress of water can affect the dielectric constant and dielectric loss of a PCB, especially when used in a humid environment.

- Dielectric Loss (DF), which affects the quality of signal transmission. The low attenuation of DK and Df is helpful to improve the signal transmission quality.

- Thermal expansion. If the materials used to build the PCB, such as copper foil, have different rates of thermal expansion, the materials may separate from each other due to temperature changes.Homogeneous structure, the substrate and copper foil must have the same thermal expansion coefficient; otherwise it will cause the copper foil to separate.

- High-frequency PCB materials also need to have high heat resistance, chemical resistance and strong resistance to peeling.

High-frequency PCB materials typically include FR4 grade glass-reinforced epoxy laminates, polyphenylene ether (PPO) resins, and Teflon. PTFE is one of the most expensive options because of its small and stable dielectric constant, low dielectric loss, and overall low water absorption. For more PCB substrate properties, please refer to “Introduction To The Material Properties Of PCB CCL“

There are many aspects to consider when selecting a high frequency PCB board and its corresponding type of PCB connector, including dielectric constant (DK), dissipation, loss and dielectric thickness.

The most important of these is the Dk of the relevant material. Materials with a high probability of dielectric constant change often experience impedance changes that disrupt the harmonics that make up the digital signal and cause an overall loss of digital signal integrity – one of the things high frequency PCBs are designed to prevent.

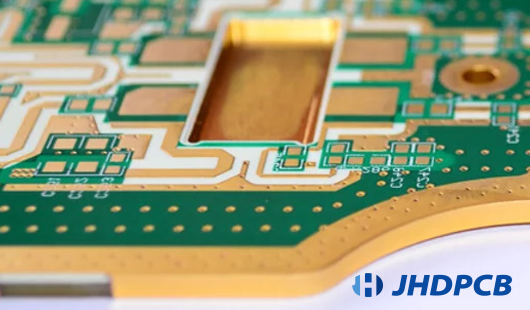

All in all, because of the performance benefits, high-frequency PCBs have been widely used in High-speed and high-density PCB designs. Anyway, you also should consider that high-frequency materials are expensive than ordinary materials. It would be best to consider the actual needs of your PCBs and make a wise decision.

A comprehensive understanding of CCL and its classification methods.

The demand for high-frequency and high-speed PCB products rises rapidly nowadays. As an experienced PCB manufacturer, JHDPCB is focusing on providing customers with reliable high-frequency PCB prototyping with high quality. If you have any problems with PCB designing or PCB manufacturing, please feel free to contact us.